Perovskite quantum dot glass film and preparation method and application thereof

A technology of quantum dot glass and perovskite, which is applied in chemical instruments and methods, instruments, luminescent materials, etc., can solve the problems of low luminescence quantum efficiency of quantum dot glass and can not reach industrial applications, and achieve wide color gamut Display and improve the effect of quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

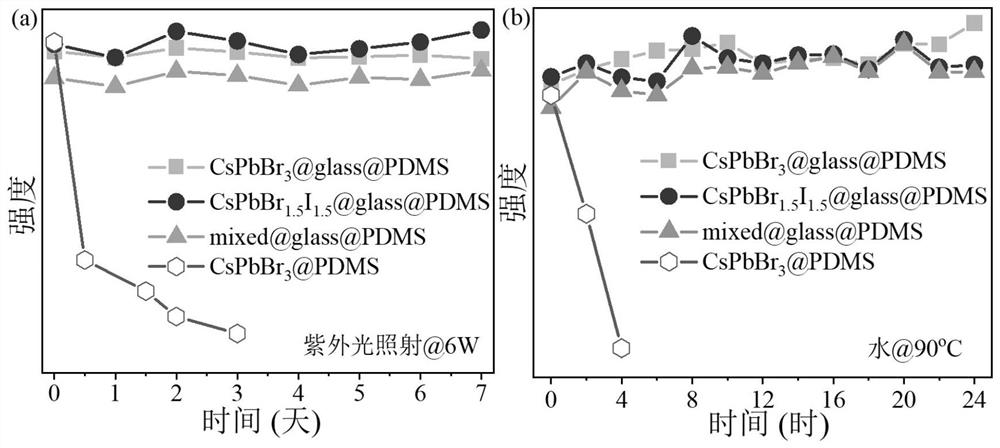

[0029] CaB 3 (X=Br, BrI) specific preparation process of perovskite quantum dot glass

[0030] The total mass is about 10g and the molar percentage is 85SiO 2 , 85B 2 o 3 , 55ZnO, 12Cs2 O. 5PbX 2 and 15NaX raw materials were put into an alumina crucible, covered and put into a muffle furnace and melted at 1200°C for 8 minutes to obtain a uniform glass melt; then, the melt was poured into a brass mold to obtain PG; finally, Heat treatment at 480-580°C for 2 hours to crystallize PG and induce CsPbX 3 In situ growth of CsPbX in glass matrix 3 Quantum dot glass.

[0031] The CsPbX 3 Quantum dot glass is CsPbBr 3 quantum dot glass, the SiO 2 , B 2 o 3 , ZnO, Cs 2 O, PbBr 2 and NaBr in a molar percentage of 85:85:55:12:5:15.

[0032] The CsPbX 3 Quantum dot glass is CsPbBr 1.5 I 1.5 Quantum dot glass, SiO 2 , B 2 o 3 , ZnO, Cs 2 O, PbBr 2 , PbI 2 , NaBr and NaI and the molar percentages are 85:85:55:12:2.5:2.5:7.5:7.5.

Embodiment 2

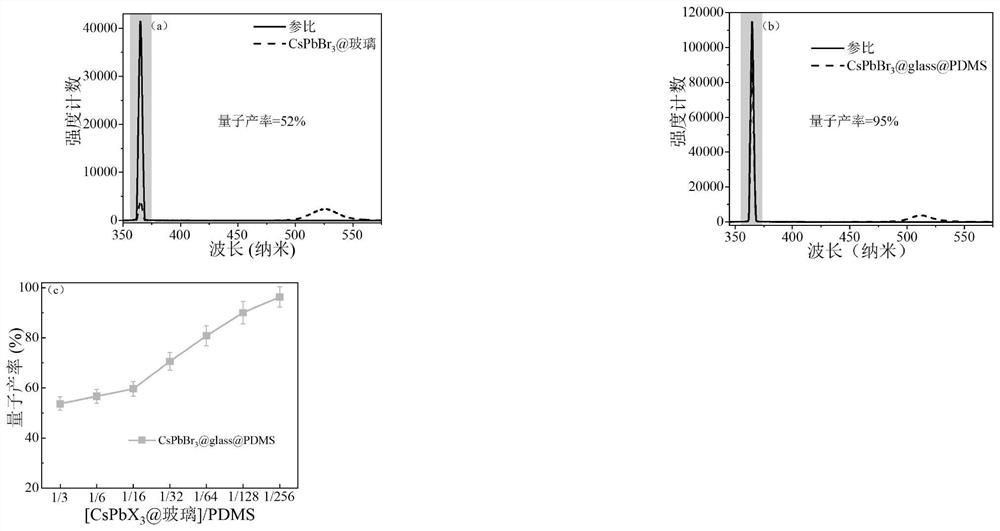

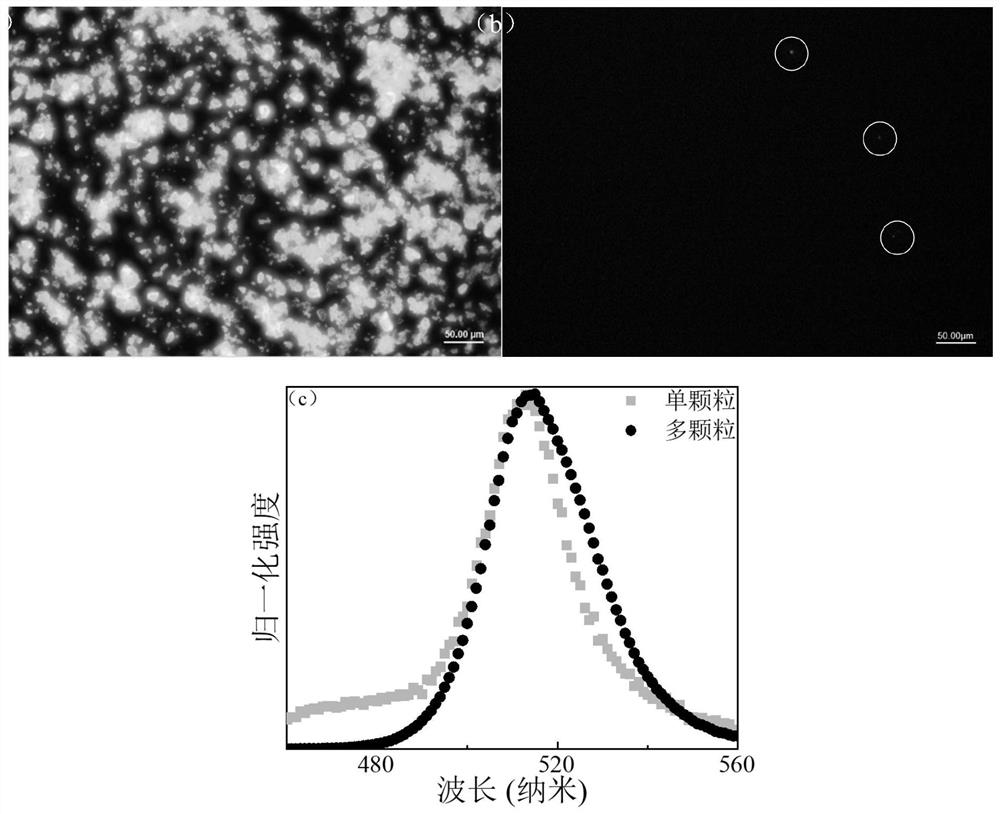

[0034] A method based on physical dilution to enhance the luminescence quantum yield of perovskite quantum dot glass

[0035] The CsPbBr prepared by the method of embodiment 1 3 Quantum dot glass (CsPbBr 3 @glass) powder crushed and ground to the average particle size of micron level and physically mixed and diluted with polydimethylsiloxane at a weight ratio of 1:3, adding quantum dot glass powder into a beaker with PDMS and stirring until uniform , to obtain a mixed colloidal liquid with a large amount of air bubbles, then inject the mixed colloidal liquid obtained by dilution into a petri dish mold of Φ90 mm polystyrene (PS) material, place it in a vacuum drying oven to vacuumize for 1 hour to remove the air bubbles, After the air bubbles are completely eliminated, turn on the heating switch, heat and cure in a vacuum environment at 80°C for 12 hours, and finally peel off to form CsPbBr 3 Quantum dot-inorganic glass-silica gel triple composite film, the obtained quantum d...

Embodiment 3

[0037] CbBr 3 Specific preparation process of quantum dot-inorganic glass-silica gel composite film

[0038] The CsPbBr prepared by the method of embodiment 1 3 The quantum dot glass powder is pulverized and ground to an average particle size of micron level and physically diluted and mixed with polydimethylsiloxane (PDMS) in a beaker at a weight ratio of 1:256 and stirred until uniform to obtain a mixed gel with a large number of bubbles liquid, and then inject the diluted mixed colloidal liquid into a Φ90 mm polystyrene (PS) petri dish mold, place it in a vacuum drying oven to vacuumize for 1 hour to remove air bubbles, and turn on the heating switch after the air bubbles are completely eliminated. Heat and cure at 80°C for 12 hours in a vacuum environment, and finally peel off to form CsPbBr 3 Quantum dots-inorganic glass-silica gel triple composite film (CsPbBr 3 @glass @PDMS).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com