Solvent-friction-corrosion-resistant scratch-resistant black shading edge-covered conductive cloth adhesive tape

A technology of friction corrosion and conductive cloth, applied in the direction of conductive adhesives, adhesives, adhesive types, etc., can solve the problems of poor solvent resistance, low yield rate, easy rebound and warping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the ink layer 10 includes the following steps: adding each component into a high-speed stirring disperser according to the above ratio, keeping the stirring speed at 1000-1200 rpm, stirring for 20-30 minutes, standing and filtering to obtain a black solvent-resistant Scratch-resistant blackout ink.

[0030] The light-shielding adhesive layer 40 is a black conductive light-shielding adhesive layer, which is composed of the following components in mass percentage: 70-80% of high-viscosity and high-temperature-resistant acrylic glue; 5-10% of conductive material; 1-3% of isocyanate curing agent; black color 4-6% pulp; 10-15% diluent.

[0031] The conductive material is composed of the following components in mass percentage: 45-65% of superfine nickel powder; 35-55% of superfine silver powder.

[0032] The preparation method of the light-shielding adhesive layer 40 includes the following steps: adding each component into a high-speed stirring dis...

Embodiment 1

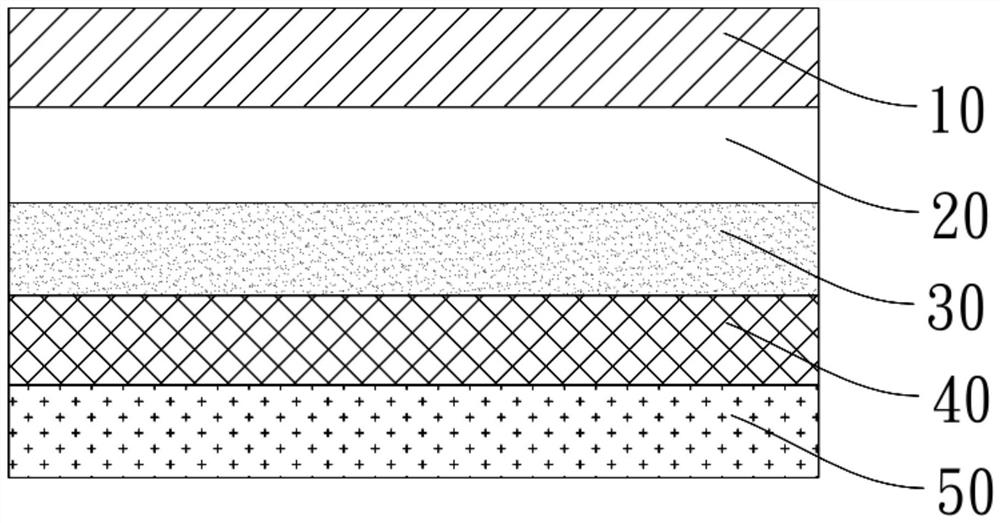

[0036] A solvent-resistant, friction-corrosion, scratch-resistant, black light-shielding and edge-wrapping conductive cloth 3 tape, the tape includes an ink layer 10, an anti-penetration layer 20, a conductive cloth 3, and a light-shielding adhesive layer 40; the ink layer 10 is arranged on the anti-penetration layer 20; the impermeable layer 20 is disposed above the conductive cloth 3; the conductive cloth 3 is disposed above the light-shielding adhesive layer 40.

[0037] The ink layer 10 is a black solvent-resistant and scratch-resistant shading ink layer, which is composed of the following components in mass percentage: 30% of nano-carbon black; 15% of polyurethane resin; 20% of solvent-resistant auxiliary agent; 5% of bridging agent, wetting 5% dispersant; 25% solvent; and 20-30% isocyanic acid crosslinking agent of the total amount of the above components.

[0038] The solvent-resistant auxiliary agent comprises the following components in mass percentage: 10-30% of nano...

Embodiment 2

[0047] A solvent-resistant, friction-corrosion, scratch-resistant, black light-shielding and edge-wrapping conductive cloth 3 tape, the tape includes an ink layer 10, an anti-penetration layer 20, a conductive cloth 3, and a light-shielding adhesive layer 40; the ink layer 10 is arranged on the anti-penetration layer 20; the impermeable layer 20 is disposed above the conductive cloth 3; the conductive cloth 3 is disposed above the light-shielding adhesive layer 40.

[0048] The difference from Example 1 is that the ink layer 10 is a black solvent-resistant and scratch-resistant shading ink layer, which is composed of the following components in mass percentages: 45% of nano-carbon black; 10% of polyurethane resin; 20% of solvent-resistant auxiliary agent %; bridging agent 5%, wetting and dispersing agent 5%; solvent 15%; also includes 20-30% isocyanic acid crosslinking agent of the total amount of the above components.

[0049] The solvent-resistant auxiliary agent comprises t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com