Small-spacing epoxy molding compound applied to outdoor display screen and preparation method thereof

A technology for epoxy molding compounds and outdoor display screens, applied in the direction of adhesive additives, triglycidyl isocyanurate adhesives, non-polymer adhesive additives, etc. LED packaging requirements, reducing the reliability of new high-power LEDs, low impact strength and other issues, to achieve the effects of easy control of process parameters, strong adhesion, and high and low temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049]A second aspect of the invention provides a method of preparing a small spacing of an outdoor display screen as described above, including the following steps:

[0050](1) According to the weight, a trihydrate glyceride epoxide epoxide epoxy resin is tapered and stirred at 100-180 ° C for 0.5-1 hours; the temperature is adjusted to 60 ° C - 12 ° C, add curing agent, chain extender, and partial additive. , Mixed with mixing for 5-40 minutes, resulting in a mixture;

[0051](2) The mixture obtained by the incubation force promoter and partial additive is added, and the mixture obtained by the step (1) is added, and the temperature is adjusted to 60-100 ° C for 5-10 minutes, and the remaining additive is added, stirred for 1-8 minutes, discharge , Cool, pulverized cake.

[0052]The above method is prepared from the outdoor display small pitch containing a low-light attenuated epoxy-based plastic seal containing an epoxy resin of the isocyanic acid trihydrate.

[0053]The above-mentioned low-...

Embodiment 1

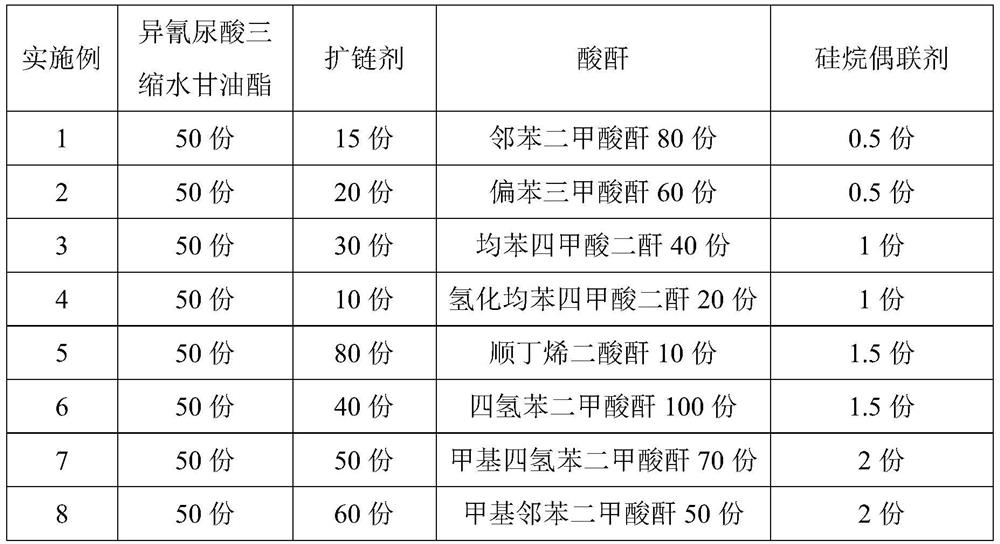

[0061]The formulation is shown in Table 1 (part of the weight), taking a trihydrate of cyanic acid trihydrate glyceride epoxide is stirred at 130 ° C for 1 hour; the temperature is adjusted to 60 ° C, add an anhydride, chain extender, and a silane coupling agent for 40 minutes. Mix is uniform to give a mixture;

Embodiment 2

[0063]The formulation is shown in Table 1 (part of the weight), taking a trihydrate of cyanic acid trihydrate glycerylate epoxy resin is stirred at 120 ° C for 1 hour; the temperature is adjusted to 80 ° C, add an anhydride, chain extender, and a silane coupling agent for 40 minutes. Mix is uniform to give a mixture;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com