High-structure-stability nickel-based high-temperature alloy and preparation method thereof

A nickel-based high-temperature alloy, stability technology, applied in the field of high-temperature alloys, to achieve the effect of less addition, good high-temperature creep performance, and strong structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

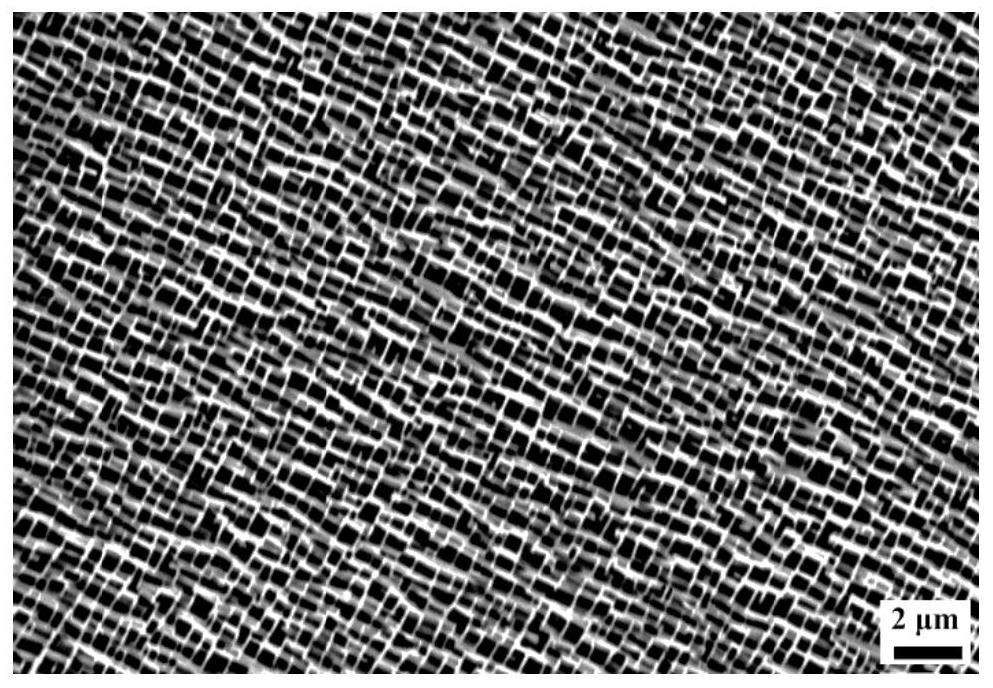

[0039] Weigh high-purity elemental metals such as Ni, Al, Co, Cr, Mo, Re, Ru, Ta, W, etc. according to the composition shown in alloy 1 in Table 1, and place the above-mentioned weighed metal raw materials in a vacuum arc melting furnace. The alloy is smelted under the protection of high-purity argon, and the current of the melting arc is controlled at 350A. After the alloy is completely liquefied, it is kept for 1 minute, and then the power is turned off and cooled until the alloy is completely solidified. Repeat the above-mentioned smelting steps 12 times to ensure the uniformity of the alloy, and finally obtain a nickel-based superalloy ingot; Heat preservation for 24 hours, air cooling, then heat preservation at 1150°C for 4 hours, air cooling, then heat preservation at 870°C for 24 hours, air cooling, to obtain a nickel-based superalloy with high structural stability. Such as figure 1 As shown in the scanning electron micrograph of the typical microstructure of the alloy...

Embodiment 2

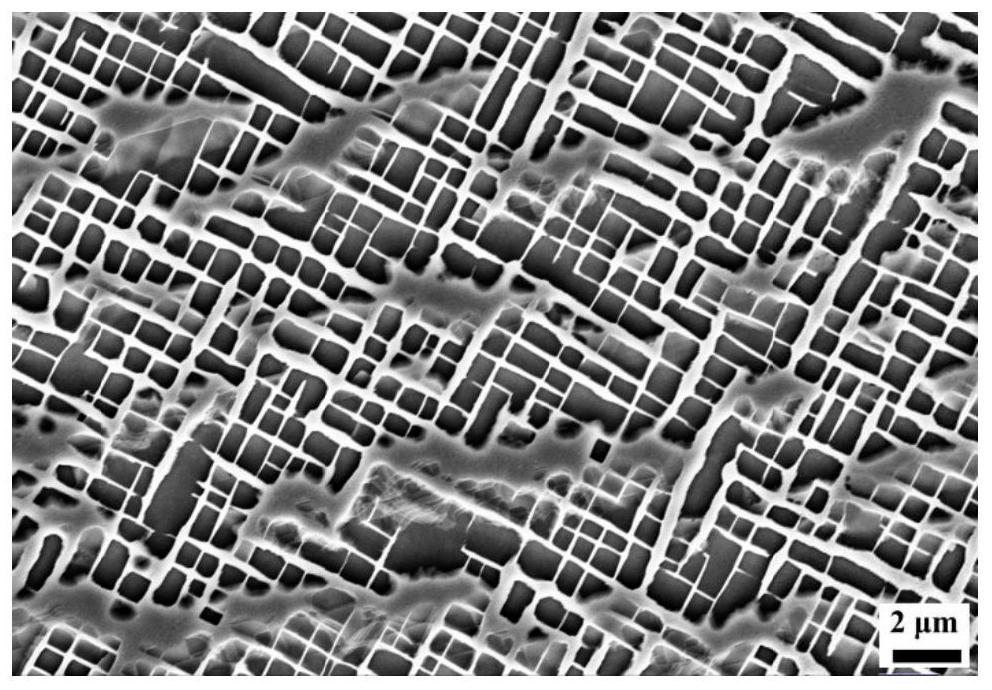

[0041] Weigh high-purity elemental metals such as Ni, Al, Co, Cr, Mo, Re, Ru, Ta, W, etc. according to the composition shown in alloy 2 in Table 1, and place the above-mentioned weighed metal raw materials in a vacuum arc melting furnace. The alloy is smelted under the protection of high-purity argon, and the current of the melting arc is controlled at 350A. After the alloy is completely liquefied, it is kept for 1 minute, and then the power is turned off and cooled until the alloy is completely solidified. Repeat the above smelting steps 12 times to ensure the uniformity of the alloy, and finally obtain a nickel-based superalloy ingot; Heat preservation for 10 hours, air cooling, then heat preservation at 1100°C for 4 hours, air cooling, then heat preservation at 870°C for 16 hours, air cooling, to obtain a nickel-based superalloy with high structural stability. Such as Figure 4 As shown in the scanning electron micrograph of the typical microstructure of the alloy in Examp...

Embodiment 3

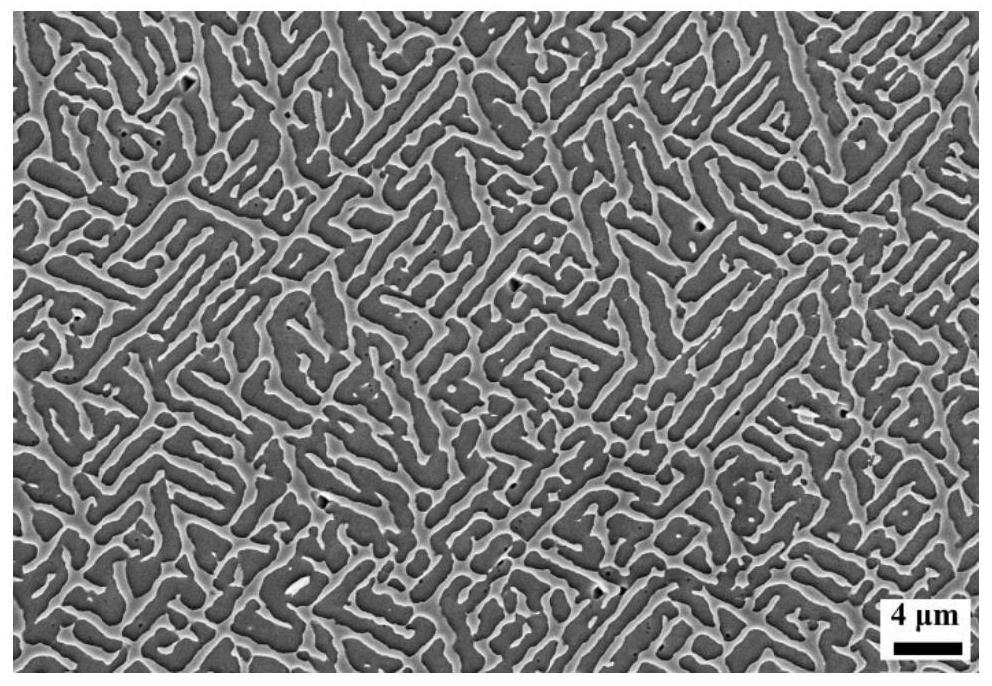

[0043] Weigh high-purity elemental metals such as Ni, Al, Co, Cr, Mo, Re, Ru, Ta, W, etc. according to the composition shown in alloy 3 in Table 1, and place the above-mentioned weighed metal raw materials in a vacuum arc melting furnace. The alloy is smelted under the protection of high-purity argon, and the current of the melting arc is controlled at 350A. After the alloy is completely liquefied, it is kept for 1 minute, and then the power is turned off and cooled until the alloy is completely solidified. Repeat the above-mentioned smelting steps 10 times to ensure the uniformity of the alloy, and finally obtain a nickel-based superalloy ingot; Heat preservation for 16 hours, air cooling, then heat preservation at 1150°C for 4 hours, air cooling, then heat preservation at 870°C for 23 hours, air cooling, to obtain a nickel-based superalloy with high structural stability. Such as Image 6 Shown is the scanning electron micrograph of the typical microstructure of the alloy of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com