Preparation method of nanofiller modified ceramic coating

A nano-filler and ceramic coating technology, which is applied in metal material coating process, coating, superimposed layer plating, etc., can solve the restrictions on the application of nano-ceramic coating materials, low thermal shock resistance, wear resistance, and combination Low strength and other problems, to achieve the effect of low cost, improved performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

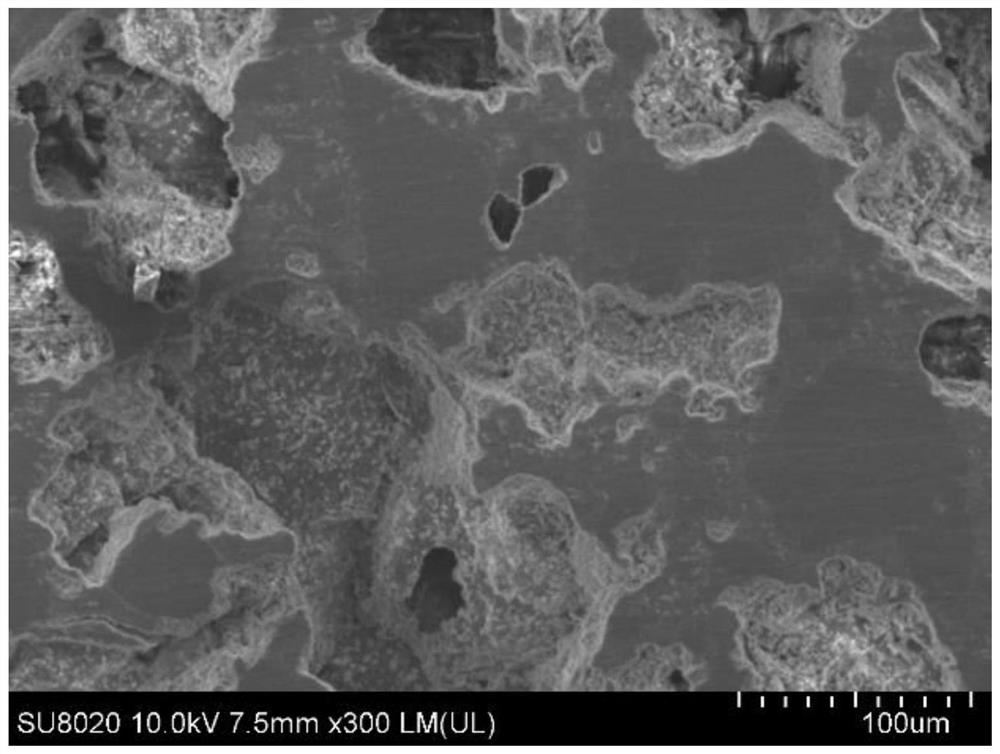

[0030] The invention provides a method for preparing a nano-filler modified ceramic coating, comprising the following steps:

[0031] The preparation method of nano filler modified ceramic coating comprises the following steps:

[0032] 1) Clean the surface: remove dust, grease and oxides on the surface of the metal substrate, and clean and dry the surface;

[0033] 2) Preparing the transition layer: roughening the surface of the metal substrate, spraying the powder of the transition layer onto the surface of the metal substrate by thermal spraying to form a bonding layer;

[0034] 3) After fully mixing the oxide powder, add it to the inorganic binder, add an appropriate amount of additives after stirring evenly, stir evenly to obtain a slurry, add nano fillers in proportion, and continue stirring evenly to obtain the final slurry;

[0035] 4) Spraying or coating the slurry on the bonding layer formed in step 2) to form a surface coating with a thickness of 150-500 μm, and dr...

Embodiment 1

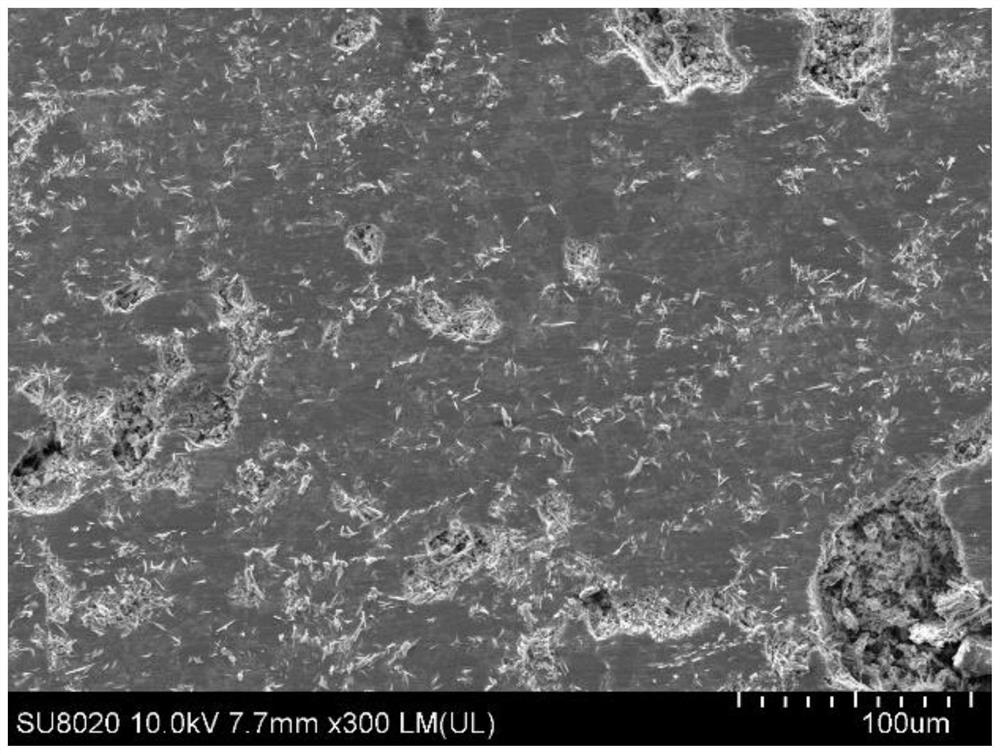

[0053] A method for preparing a nano-filler modified ceramic coating, comprising the following steps:

[0054] 1) Clean the surface: remove dust, grease and oxides on the surface of the metal substrate, and clean and dry the surface;

[0055] 2) Preparation of the transition layer: roughen the surface of the metal substrate by sandblasting, and spray the powder of the transition layer onto the surface of the metal substrate by thermal spraying to form a bonding layer with a thickness of 100 μm;

[0056] 3) Mix the oxide powder thoroughly and add it to the sodium silicate. After stirring evenly, add an appropriate amount of silicone defoamer. After stirring evenly to obtain a slurry, add nano-alumina powder and nano-zirconia powder in proportion, and continue stirring The final slurry is uniformly obtained, and the powder is composed of the following raw materials in parts by weight: 47% of silicon oxide; 25% of aluminum oxide; 22% of zirconia; 6% of titanium oxide; The weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com