A large diameter slag discharge gate valve

A slag discharge gate valve, large-diameter technology, applied in valve devices, valve details, sliding valves, etc., can solve problems such as valve jamming, accumulation, pipeline blockage, etc., to avoid pipeline blockage, speed up work efficiency, and speed up flow The effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

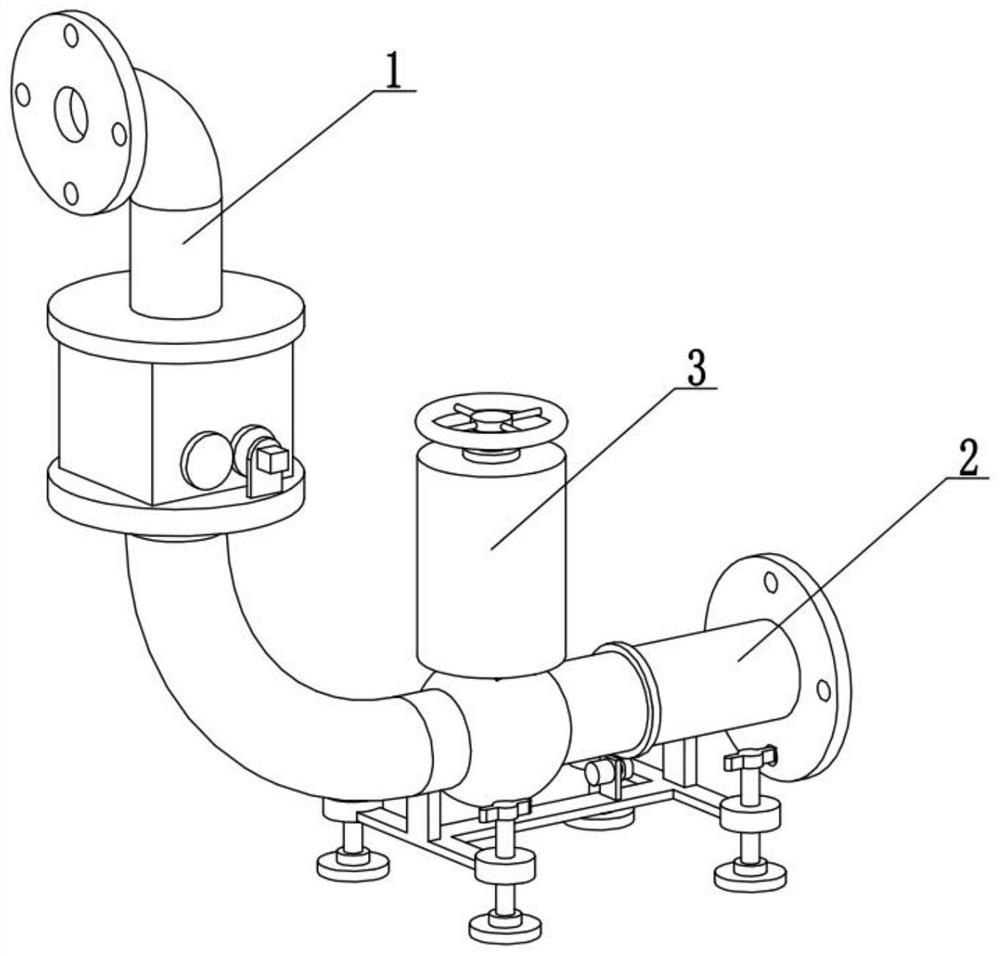

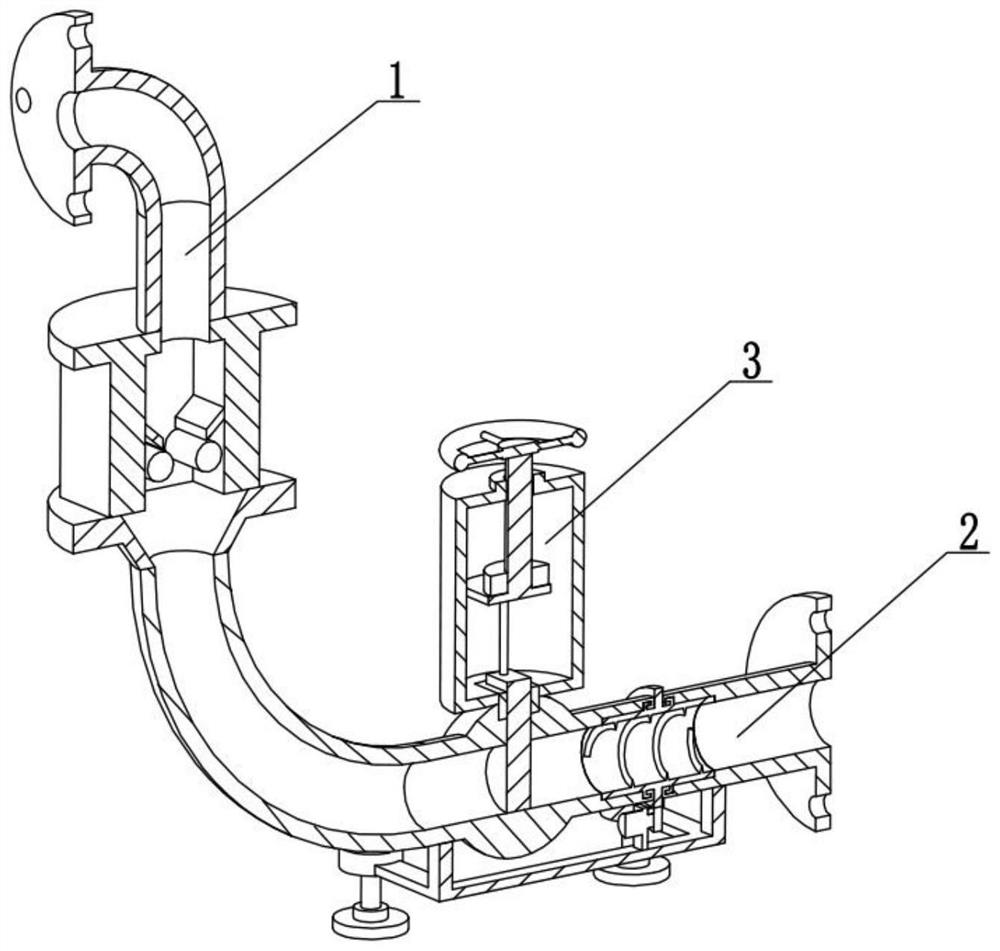

[0025] The present embodiment will be described below, and the present invention relates to the field of slag groove valve, and more particularly to a large-diameter slagable gate valve, including a slag pulverizing assembly 1, a power lifting assembly 2, and a opening and closing gate assembly 3, said The slag pulverization assembly 1 is connected to the left end of the power lifting assembly 2, and the opening and closing gate assembly 3 is connected to the top end of the power lifting assembly 2.

[0026] The slag pulverizing assembly 1 pulverizes the large particle residue in the incoming segments, so that the size of the slag disintegrating the slag pulverized assembly 1 is maintained in a small range, so that the size of the particles is uniform, avoiding In the pipeline, the slag stacked or blocked in the line due to the bending, turning of the line, and also avoids the large particle material residue card to the opening and opening and opening and opening and opening and o...

specific Embodiment approach 2

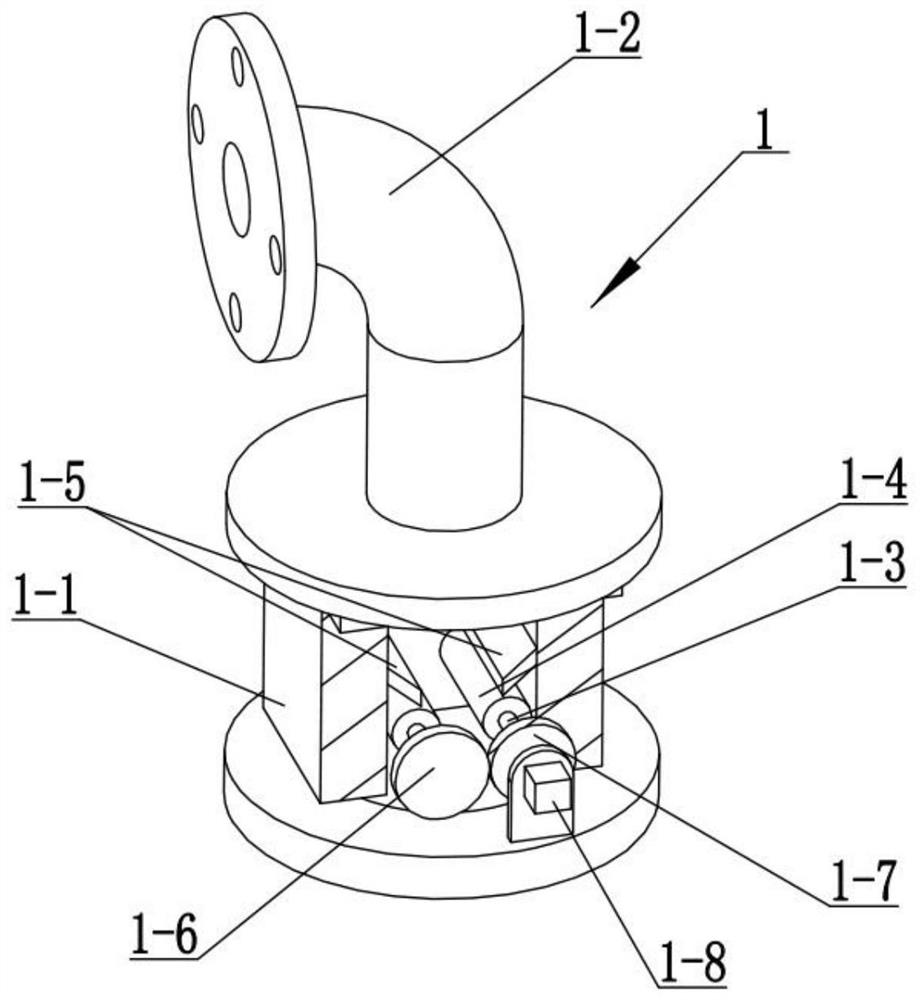

[0027] The present embodiment will be described below, and the present embodiment will further explain the embodiment, and the slag pulverization assembly 1 includes a rectangular aisle 1-1, an inlet connection opening 1-2, a rotating shaft 1-3, a pulverizing roller 1 -4, gathered slant plate 1-5, follow-up gear 1-6, active gear 1-7, and pulverizing motor 1-8, the water connection port 1-2 is fixed to the top of the rectangular aisle 1-1, two rotation The front and rear ends of the shafts 1-3 are rotated on the front and rear inner walls of the rectangular aisle 1-1, and the two rotation shafts 1-3 mirror are set, and the two pulverizing rollers 1-4 are fixed to the two rotation shafts 1-3, respectively. At the end, the follow-up gear 1-6 is fixed to the front end of the rotation shaft 1-3 located on the left end, the active gear 1-7 is fixed to the front end of the rotating shaft 1-3 located at the right end, the rotation gear 1-6 and the active gear 1-7 Meshing Transmission, the...

specific Embodiment approach 3

[0029] The present embodiment will be described below with reference to the second embodiment, and the second embodiment is further explained by the second embodiment, and the secondary gear 1-6 index circular diameter is a five-fold five times the diameter of the active gear 1-7 indexing circle; The gear 1-6 and the active gear 1-7 rotate have a differential, and while the large particles are extruded while extruding the large particles, the large particles are frictionally pulverized, and the large particle material slag is more thorough, increased. The pulverization of large particles slag can be quickly pulverized to avoid large particle slag binding between two pulverizing rollers 1-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com