Method and equipment for electrochemically depositing metal pattern

A technology for depositing metal and deposition equipment, which is applied in the field of solar cells, can solve the problems of large footprint and easy generation of fragments, and achieve the effects of small footprint, less potion configuration, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

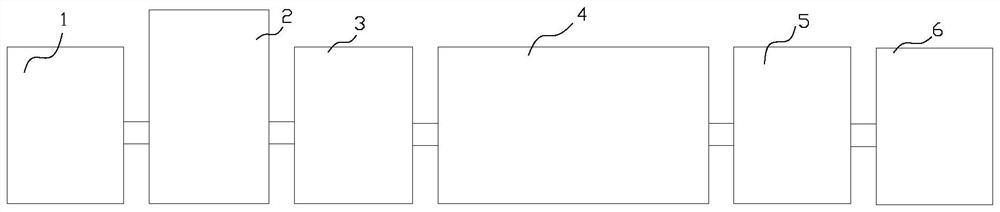

[0043] Take the fabrication of metal grid wire electrodes on the surface of solar cells as an example.

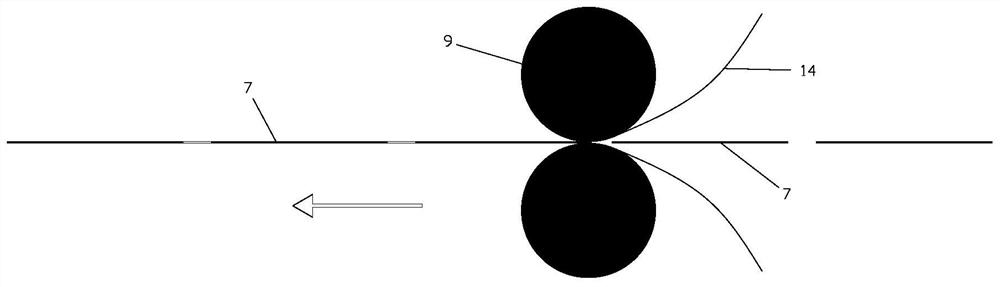

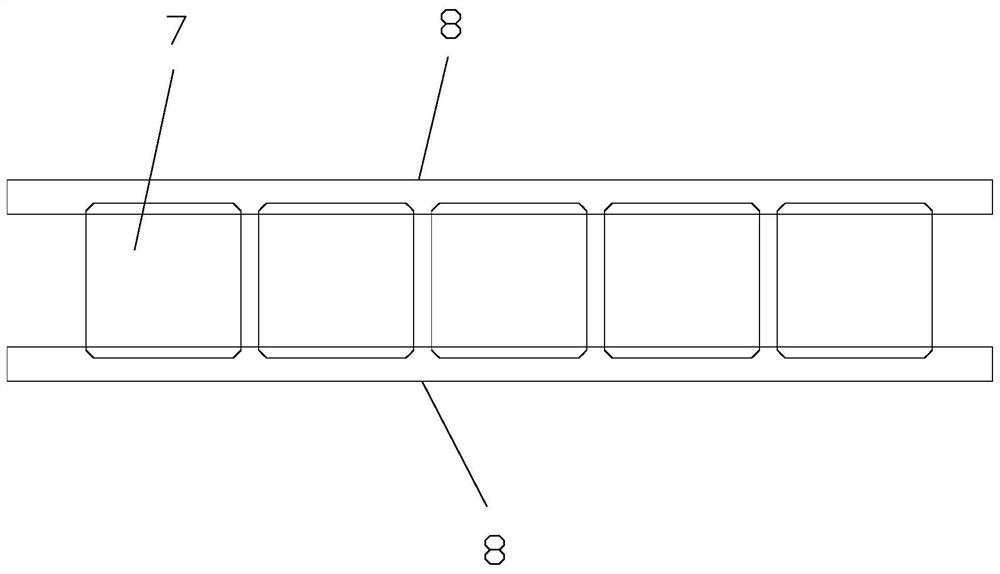

[0044] The solar cells (that is, the substrate 7) are conveyed in a horizontal manner, and at the same time, the conductive tape 8 and the photosensitive film 14 are bonded to the upper and lower surfaces of the solar cells through the film roller 9 to form a string of solar cells; after the film is pasted, the horizontal transfer To the exposure device 2, after the exposure machine performs automatic positioning, it exposes on both sides of the area where the solar cell is located, and completes the graphic transfer; after exposure, the solar cell is horizontally transferred to the development device 3 for double-sided development, and the required grid pattern Developed; then horizontally transported to the metal deposition equipment 4, using the cathode fixing assembly 12 to connect the entire string of battery sheets, the cathode fixing assembly 12 can not only provide e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com