Perovskite precursor solution, preparation method and application thereof

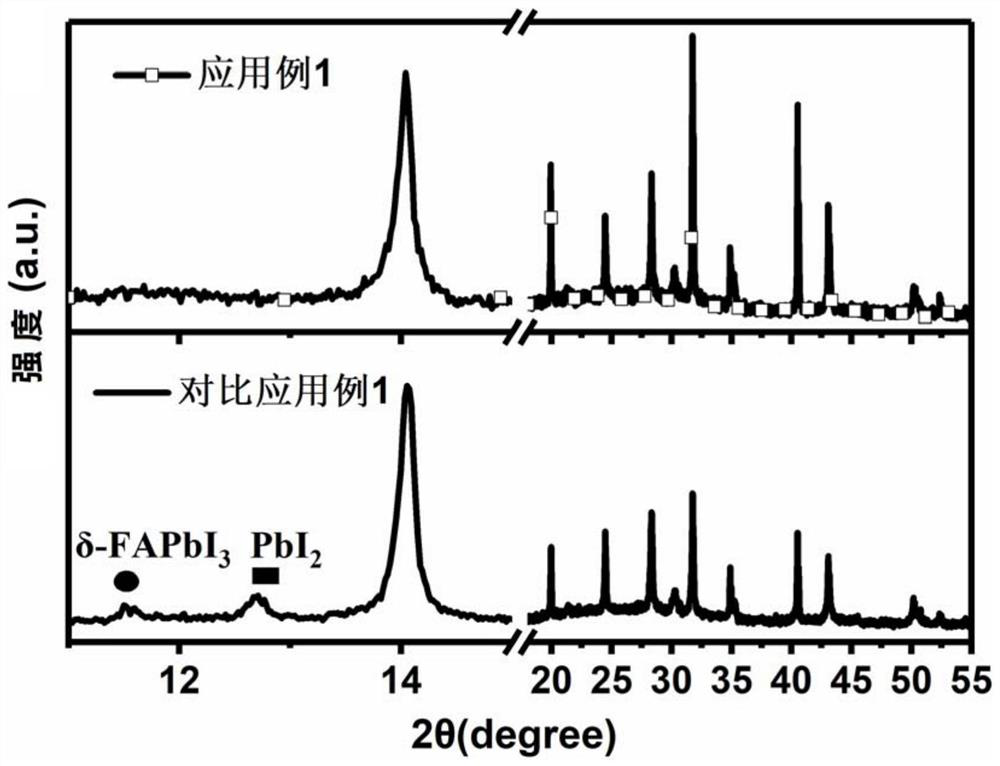

A perovskite precursor and precursor solution technology, applied in the field of perovskite precursor solution and its preparation, can solve the problems of unfavorable saving of production cost, unfavorable commercial application, high weighing accuracy requirements, and achieve less defects, The effect of good air stability and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

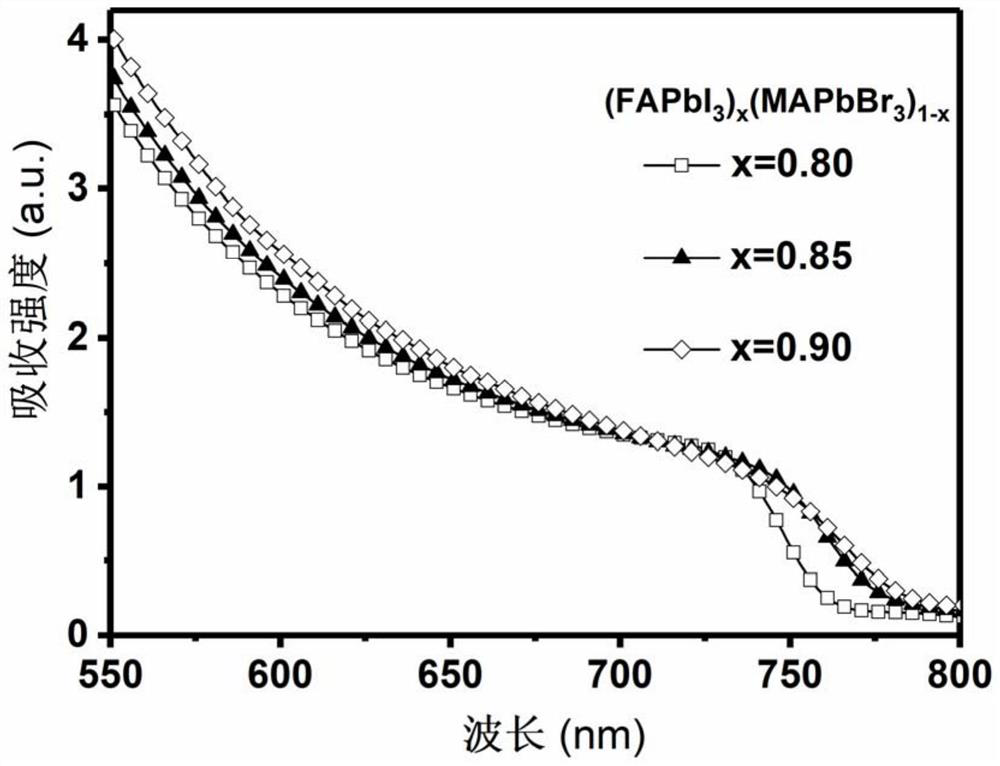

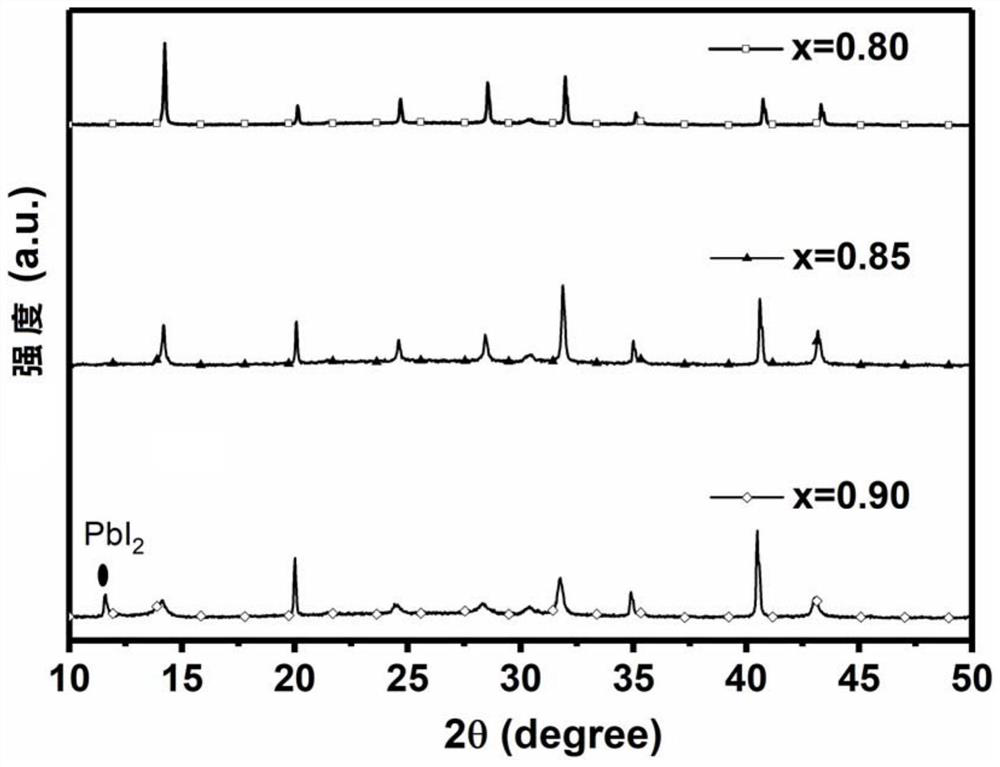

Embodiment 1

[0051] This embodiment provides a perovskite precursor solution and a preparation method thereof, the preparation method comprising the following steps:

[0052] (1) Mix 753.2mg of FAPbI at 65°C for 20min at a rate of 800rpm 3 powder and polar solvent to obtain FAPbI 3 An intermediate precursor solution with a concentration of 1.5mol / L; the composition of the polar solvent is: 80% N,N-dimethylformamide+20% dimethyl sulfoxide (V / V);

[0053] (2) Mix 100.6 mg of MAPbBr at 65°C for 20 min at a rate of 800 rpm 3 The single crystal and the intermediate precursor solution obtained in step (1) are filtered through a polytetrafluoroethylene filter membrane with an average pore diameter of 0.22 μm to obtain a perovskite precursor solution.

[0054] In this example, the MAPbBr 3 Single crystal with FAPbI 3 The molar ratio of the powder is 0.15:0.85.

Embodiment 2

[0056] This embodiment provides a kind of perovskite precursor solution and preparation method thereof, in the preparation method except described MAPbBr 3 Single crystal with FAPbI 3 The mol ratio of powder is changed into 0.2:0.8, that is to say FAPbI described in step (1) 3 The quality of powder is changed into 708.8mg, and step (2) described MAPbBr 3 The mass of the single crystal was changed to 134.1 mg, and the rest of the conditions were the same as in Example 1, so details are not repeated here.

Embodiment 3

[0058] This embodiment provides a kind of perovskite precursor solution and preparation method thereof, in the preparation method except described MAPbBr 3 Single crystal with FAPbI 3 The mol ratio of powder is changed into 0.1:0.9, that is to say FAPbI described in step (1) 3 The quality of powder is changed into 797.5mg, and step (2) described MAPbBr 3 The mass of the single crystal was changed to 67.1 mg, and the rest of the conditions were the same as in Example 1, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com