Method for preparing fishy smell-removed fish albumen glue by using superheated steam to promote glycosylation

A superheated steam and fish protein technology, applied in the direction of fish protein composition, animal protein processing, protein food composition, etc. The effect of shortening extraction time, improving emulsification and foaming, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

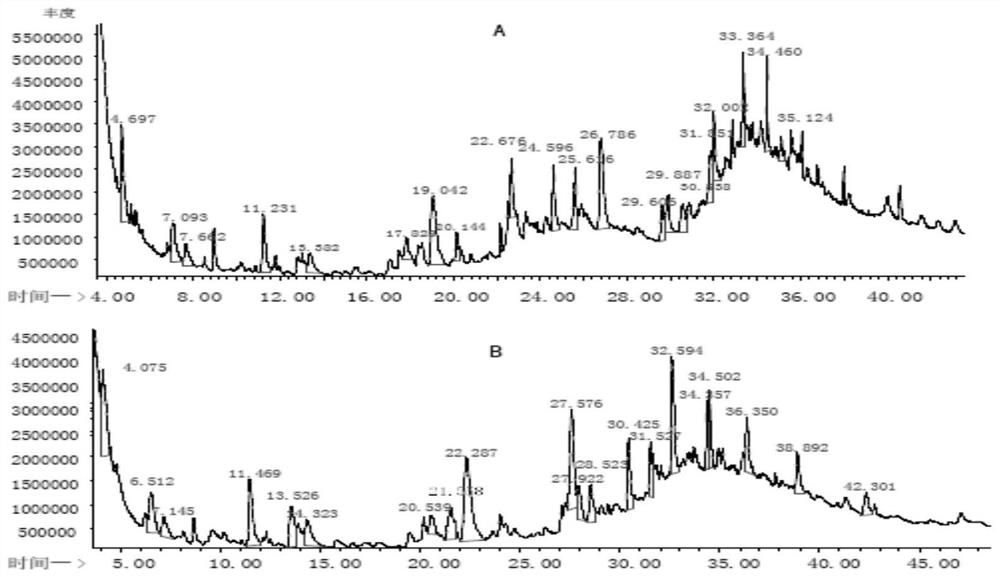

[0033] Embodiment one, figure 1 It is the GC-MS chromatogram of fish protein glue volatile matter before and after the deodorization of embodiment one, as figure 1 shown, including the following steps: S1, degreasing treatment

[0034] Use the snakehead skin as raw material, remove the scales and flesh on the surface of the skin, and then perform degreasing treatment;

[0035] Preferably, in step S1, after removing fish scales and fish meat on the surface of the fish skin, it is necessary to drain the water and cut it into pieces, and cut it into a sheet of 2cm × 2cm in step S1. Then use organic reagents to extract and degrease. In step S1, the organic reagent is an isopropanol solution with a volume fraction of 10-30%, the solid-liquid ratio of snakehead skin and isopropanol is 1:10g:mL, the extraction and degreasing time is 24 hours, and the extraction and degreasing temperature is 4°C.

[0036] S2, fish protein glue mother liquor preparation

[0037] adding the degrease...

Embodiment 2

[0068] Embodiment two, comprising the following steps: S1, degreasing treatment

[0069] Use the snakehead skin as raw material, remove the scales and flesh on the surface of the skin, and then perform degreasing treatment;

[0070] Preferably, in step S1, after removing fish scales and fish meat on the surface of the fish skin, it is necessary to drain the water and cut it into pieces, and cut it into a sheet of 2cm × 2cm in step S1. Then use organic reagents to extract and degrease. In step S1, the organic reagent is an isopropanol solution with a volume fraction of 10-30%, the solid-liquid ratio of snakehead skin and isopropanol is 1:10g:mL, the extraction and degreasing time is 24 hours, and the extraction and degreasing temperature is 4°C.

[0071] S2, fish protein glue mother liquor preparation

[0072] adding the degreased fish skin in step S1 to the compound organic acid, extracting the fish protein glue under ultrasonic treatment, and obtaining the fish protein glue...

Embodiment 3

[0087] Embodiment 3, the difference between this embodiment and embodiment 1 is: omit the two-step deodorization step of superheated steam glycosylation in step S6, and the rest is the same as embodiment 1.

[0088] Adopt the assay method described in embodiment 1 to measure deproteinized rubber emulsifying properties and foaming properties, the experimental results show that the emulsifying power and emulsifying stability of fish protein glue are respectively 72m 2 / g and 9min, the foaming ability and foaming stability were 101% and 54%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emulsion stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com