Preparation method and application of iron-doped cobalt imidazolate hollow nano catalytic material

A technology of cobalt imidazolate nanometer and catalytic material, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as high cost, save time and The effect of large cost and storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

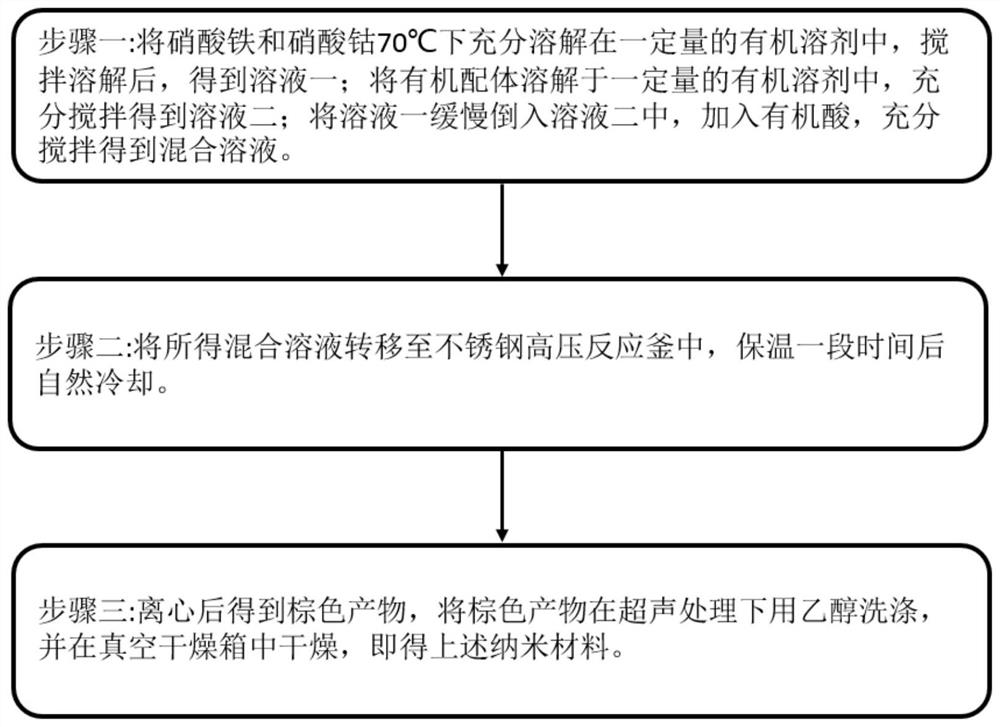

[0035] like figure 1 As shown, the preparation method of the iron-doped cobalt imidazolate nanomaterial provided by the embodiments of the present invention comprises the following steps:

[0036] 1) Fully dissolve ferric nitrate and cobalt nitrate in a certain amount of organic solvent at 70°C, stir and dissolve to obtain solution 1; dissolve the organic ligand in a certain amount of organic solvent, and fully stir to obtain solution 2; Slowly pour one into solution two, add organic acid, and stir thoroughly to obtain a mixed solution.

[0037] 2) The resulting mixed solution is transferred to a stainless steel autoclave, and naturally cooled after being kept warm for a period of time;

[0038] 3) A brown product is obtained after centrifugation, and the brown product is washed with ethanol under ultrasonic treatment, and dried in a vacuum oven to obtain the above-mentioned nanomaterial.

[0039] The preparation method of the iron-doped cobalt imidazolate nanomaterial provi...

Embodiment 1

[0056] The preparation method of the iron-doped cobalt imidazolate nanomaterial provided by the embodiments of the present invention comprises the following steps:

[0057] Firstly, dissolve 0.066g of ferric nitrate and 0.218g of cobalt nitrate in 15mL of organic solvent, and fully stir to form solution 1. Dissolve 0.98g of organic ligand in 15mL of organic solvent and stir well to form solution 2. Slowly pour solution 1 into solution 2 to form a mixed solution, add 100 μL of organic acid, then stir the mixed solution rapidly at room temperature for 15 min, then transfer the mixture to a stainless steel autoclave, and put the autoclave into Keep it in an oven at 160°C for 12 hours; finally, after the temperature of the autoclave is cooled to room temperature, the mixture is centrifuged and washed to obtain a brown precipitate, which is ultrasonically dispersed and washed several times with absolute ethanol. It was collected by centrifugation and dried in a vacuum dryer for 6h...

Embodiment 2

[0059] The preparation method of the iron-doped cobalt imidazolate nanomaterial provided by the embodiments of the present invention comprises the following steps:

[0060] Firstly, 0.06g of ferric nitrate and 0.174g of cobalt nitrate were dissolved in 15mL of organic solvent, and fully stirred to form solution 1. Dissolve 0.98g of organic ligand in 15mL of organic solvent and stir well to form solution 2. Slowly pour solution 1 into solution 2 to form a mixed solution, add 100 μL of organic acid, then stir the mixed solution rapidly at room temperature for 15 min, then transfer the mixture to a stainless steel autoclave, and put the autoclave into Keep it in an oven at 160°C for 12 hours; finally, after the temperature of the autoclave is cooled to room temperature, the mixture is centrifuged and washed to obtain a brown precipitate, which is ultrasonically dispersed and washed several times with absolute ethanol. It was collected by centrifugation and dried in a vacuum drye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com