Equipment for continuous online analysis of alkalinity of working solution in anthraquinone-process preparation of hydrogen peroxide and use method of equipment

A technology for analyzing equipment and working fluids, applied in chemical instruments and methods, analytical materials, peroxides/peroxyhydrates/peroxyacids/superoxides/ozonides, etc. Problems such as real pH, non-guiding significance for production, complex components, etc., to achieve continuous online analysis, reduce labor intensity, and achieve accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

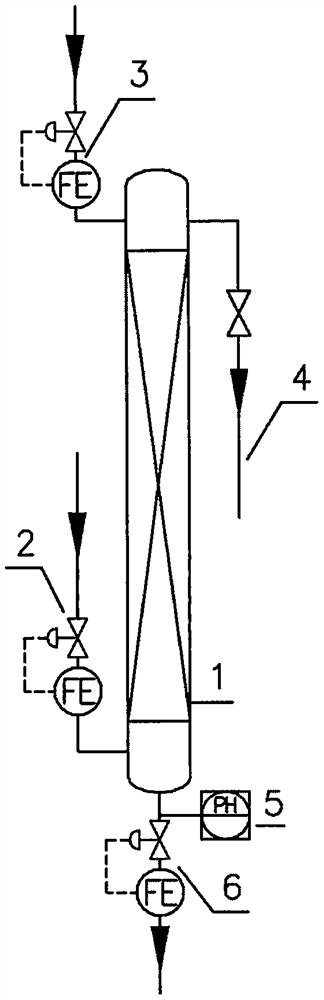

Image

Examples

Embodiment 1

[0024] A hydrogen peroxide model test device is installed with the above-mentioned continuous online analysis equipment for the alkalinity of the working fluid. The working fluid controls the flow rate of 100L / h and enters the extraction column from the bottom of the extraction column (the ratio of height to diameter is 100:1, and the metal mesh θ ring is highly efficient packing). Pure water controls the flow rate of 10L / h to extract the water-soluble lye in the working fluid.

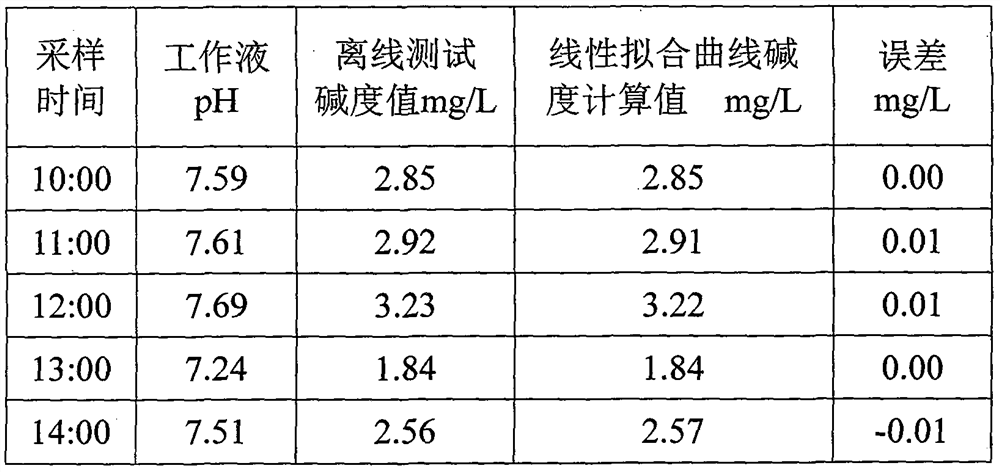

[0025] The operator takes samples at the site every hour. The alkalinity of the samples is measured in the laboratory using an off-line method. At the same time, the pH value is measured with an on-site alkalinity online analyzer, and the alkalinity is calculated using a linear fitting curve. The experimental results are shown in Table 1.

[0026] It can be seen from Table 1 that the error between the offline test alkalinity value and the linear fitting curve alkalinity calculation value is between ±0...

Embodiment 2

[0030] A 100,000-ton / year (27.5%) hydrogen peroxide plant is installed with the above-mentioned continuous on-line analysis equipment for the alkalinity of the working fluid. Net θ ring high-efficiency packing), pure water control flow rate 100L / h to extract the water-soluble lye in the working fluid.

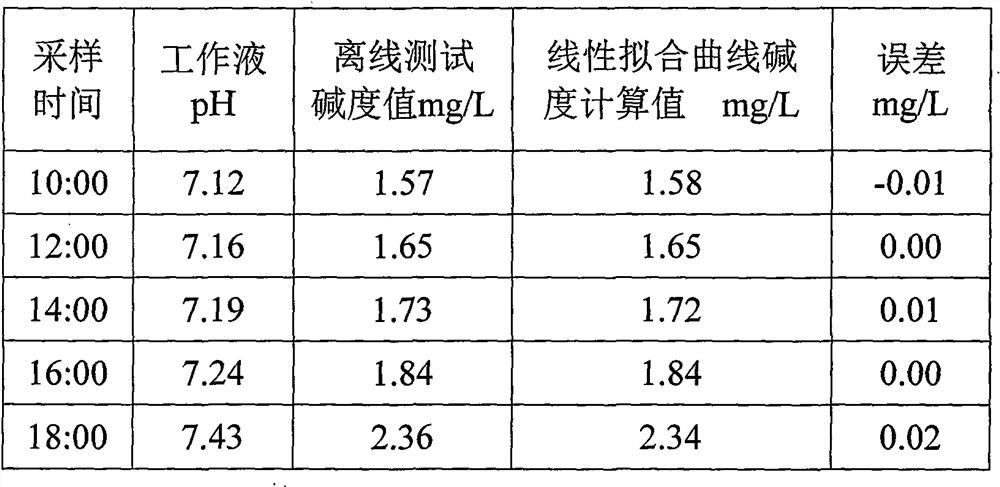

[0031] Every 2 hours, the operator goes to the site to take samples, and the samples go to the laboratory to measure their alkalinity offline. At the same time, the on-site alkalinity online analyzer is used to measure the pH value, and the linear fitting curve is used to calculate the alkalinity. The experimental results are shown in Table 2.

[0032] Table 2 offline test alkalinity value and linear fitting curve alkalinity calculation value comparison

[0033]

[0034] It can be seen from Table 2 that the error between the offline test alkalinity value and the linear fitting curve alkalinity calculation value is between ±0.02mg / L, which meets the test requirement of error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com