Polyurethane sealant

A polyurethane sealant and isocyanate-terminated technology, used in the field of sealants, can solve the problems of increased modulus of the sealant, environmental pollution, low volatility, etc., and achieve the effects of prolonging service life, high purity, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of carboxyl-containing chlorinated paraffin 42: Dissolve 20 g of chlorinated paraffin 42 in 210 mL of acetone, stir to dissolve, add 20 g of p-hydroxybenzoic acid and 28 g of potassium carbonate, and react at 55° C. for 30 h under nitrogen protection. After the reaction, the pH was adjusted to 3.0 with hydrochloric acid, and then extracted with ethanol, and the product was vacuum-dried at 100° C. for 5 h to obtain carboxyl-containing chlorinated paraffin 42.

[0027] (2) Preparation of chlorinated paraffin 42 containing acid chloride: add 70mol carboxyl-containing chlorinated paraffin 42 to the reaction kettle, add dropwise 85mol phosphorus trichloride, stir and heat up to 70°C, react for 4h, cool to room temperature, and stand to separate Layer to obtain chlorinated paraffin 42 containing acid chloride.

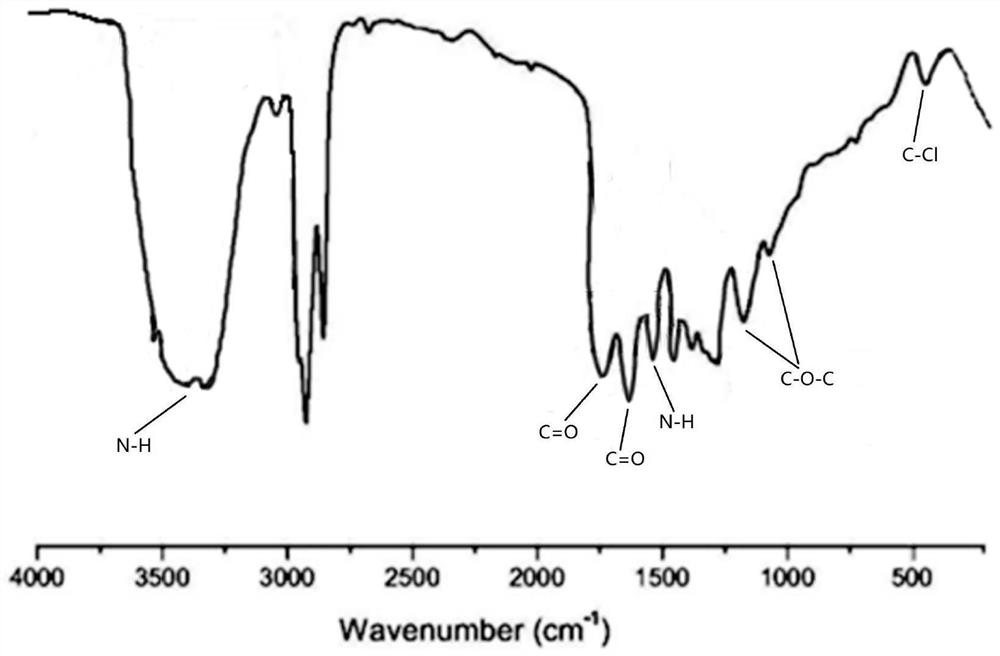

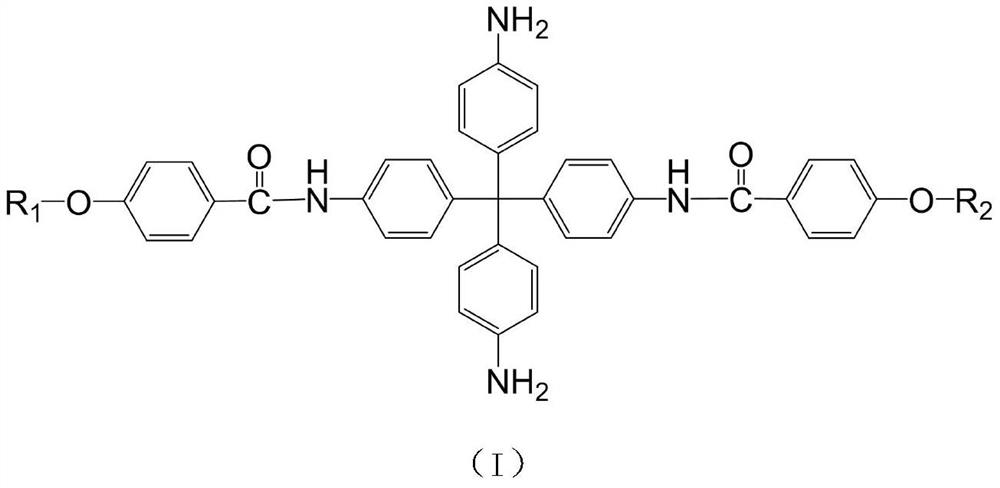

[0028] (3) Preparation of chlorinated paraffin 42 modified diamine: add 100mol anhydrous dichloromethane, 50mol tetrakis(4-aminophenyl)methane and an ...

Embodiment 2

[0030] (1) Preparation of carboxyl-containing chlorinated paraffin 52: Dissolve 20 g of chlorinated paraffin 52 in 220 mL of acetone, stir to dissolve, add 20 g of p-hydroxybenzoic acid and 29 g of potassium carbonate, and react at 80° C. for 10 h under nitrogen protection. After the reaction, the pH was adjusted to 3.0 with hydrochloric acid, and then extracted with ethanol. The product was vacuum-dried at 100° C. for 5 h to obtain carboxyl-containing chlorinated paraffin 52.

[0031] (2) Preparation of chlorinated paraffin 52 containing acid chloride: add 70 mol of chlorinated paraffin 52 containing carboxyl to the reaction kettle, dropwise add 85 mol of phosphorus trichloride, stir and heat up to 50°C, react for 6 hours, cool to room temperature, let stand to separate layer to obtain the chlorinated paraffin 52 containing the acid chloride.

[0032] (3) Preparation of chlorinated paraffin 52 modified diamine: add 100mol anhydrous dichloromethane, 50mol tetrakis(4-aminopheny...

Embodiment 3

[0034] (1) Preparation of carboxyl-containing chlorinated paraffin 70: Dissolve 20 g of chlorinated paraffin 70 in 200 mL of acetone, stir to dissolve, add 20 g of p-hydroxybenzoic acid and 30 g of potassium carbonate, and react at 65° C. for 24 h under nitrogen protection. After the reaction, the pH was adjusted to 3.0 with hydrochloric acid, and then extracted with ethanol, and the product was vacuum-dried at 100°C for 5 hours to obtain carboxyl-containing chlorinated paraffin 70.

[0035] (2) Preparation of chlorinated paraffin 70 containing acid chloride: add 70mol carboxyl-containing chlorinated paraffin 70 to the reaction kettle, add dropwise 85mol phosphorus trichloride, stir and heat up to 60°C, react for 5h, cool to room temperature, and stand to separate layer to obtain chlorinated paraffin 70 containing acid chloride.

[0036] (3) Preparation of chlorinated paraffin 70 modified diamine: add 100mol anhydrous dichloromethane, 50mol tetrakis(4-aminophenyl)methane and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com