Novel composite material for sterilization, disinfection and rapid hemostasis as well as preparation and application

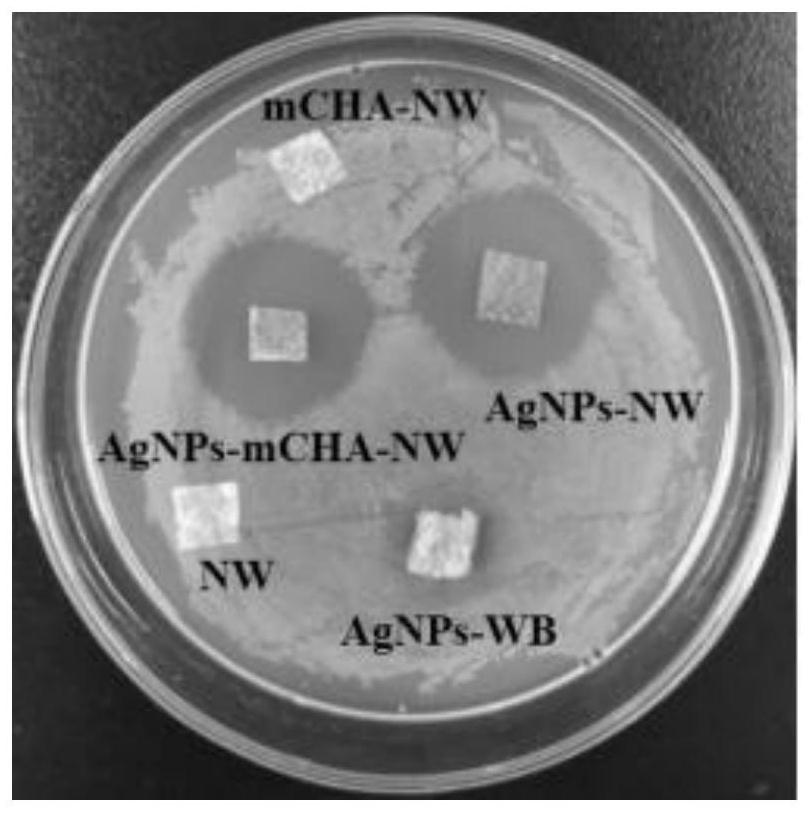

A composite material, sterilization and disinfection technology, applied in the field of biomedicine, can solve the problems of easy loss of active ingredients, easy contamination of wounds, and unsatisfactory hemostasis effect on irregular-shaped wounds, so as to prevent wound infection, quickly and effectively stop bleeding, and inhibit bacterial growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

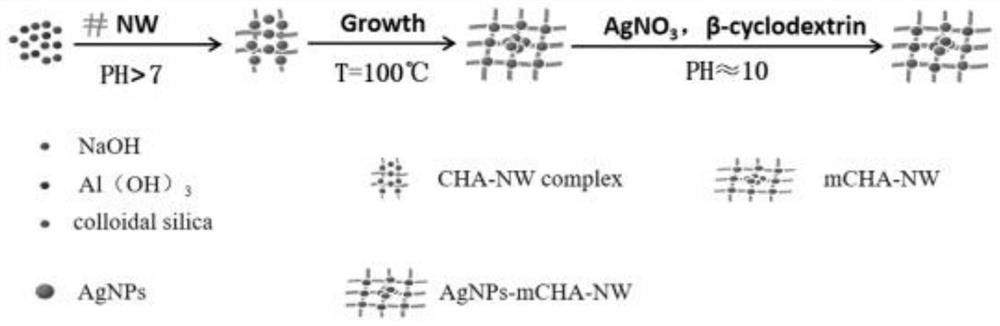

[0074] Preparation of mCHA-NW

[0075] Take 0.25g NaOH and 0.068g Al(OH) 3 Add it into 16.0mL ultrapure water, put it in a stainless steel autoclave at 100°C for 18 hours to dissolve it completely, and prepare A solution. Take 0.2g NaOH and 1.25g silica gel (30wt%) and add it into 6.8mL ultrapure water, stir at room temperature for 12h to dissolve completely, and prepare solution B. The prepared A solution was added dropwise to the B solution. During the dropwise addition, the B solution was vigorously stirred at room temperature. After the dropwise addition, the mixed solution continued to be vigorously stirred at room temperature for 3-4 hours. Take 0.2-0.3g of non-woven fabric and cut it into small squares of 2-3cm, put it into the above mixed solution, soak it at room temperature for 3-4h, put it in a 100℃ reactor for hydrothermal crystallization for 24h, and finally soak it in 0.5M CaCl 2 In the solution for 12h, soak twice at room temperature.

Embodiment 2

[0077] Preparation of mCHA-NW

[0078] Take 0.5g NaOH and 0.136g Al(OH) 3 Add it into 16.0mL ultrapure water, put it in a stainless steel autoclave at 100°C for 18 hours to dissolve it completely, and prepare A solution. Take 0.4g NaOH and 2.5g silica gel (30wt%) and add it into 6.8mL ultrapure water, stir at room temperature for 12h to dissolve completely, and prepare solution B. The prepared A solution was added dropwise to the B solution. During the dropwise addition, the B solution was vigorously stirred at room temperature. After the dropwise addition, the mixed solution continued to be vigorously stirred at room temperature for 3-4 hours. Take 0.2-0.3g of non-woven fabric and cut it into small squares of 2-3cm, put it into the above mixed solution, soak it at room temperature for 3-4h, put it in a 100℃ reactor for hydrothermal crystallization for 24h, and finally soak it in 0.5M CaCl 2 In the solution for 12h, soak twice at room temperature.

Embodiment 3

[0080] Preparation of mCHA-NW

[0081] Take 1.0g NaOH and 0.273g Al(OH) 3 Add it into 16.0mL ultrapure water, put it in a stainless steel autoclave at 100°C for 18 hours to dissolve it completely, and prepare A solution. Take 0.8g NaOH and 5.0g silica gel (30wt%) and add it into 6.8mL ultrapure water, stir at room temperature for 12h to dissolve completely, and prepare solution B. The prepared A solution was added dropwise to the B solution. During the dropwise addition, the B solution was vigorously stirred at room temperature. After the dropwise addition, the mixed solution continued to be vigorously stirred at room temperature for 3-4 hours. Take 0.2-0.3g of non-woven fabric and cut it into small squares of 2-3cm, put it into the above mixed solution, soak it at room temperature for 3-4h, put it in a 100℃ reactor for hydrothermal crystallization for 24h, and finally soak it in 0.5M CaCl 2 In the solution for 12h, soak twice at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com