On-line analysis equipment for alkalinity of working solution in preparation of hydrogen peroxide by anthraquinone process and use method thereof

An analytical equipment, hydrogen peroxide technology, applied in chemical instruments and methods, program control in sequence/logic controllers, analytical materials, etc., can solve problems that cannot reflect the true pH of the working fluid, production has no guiding significance, and discrete to achieve continuous online analysis, reduce labor intensity, and achieve accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

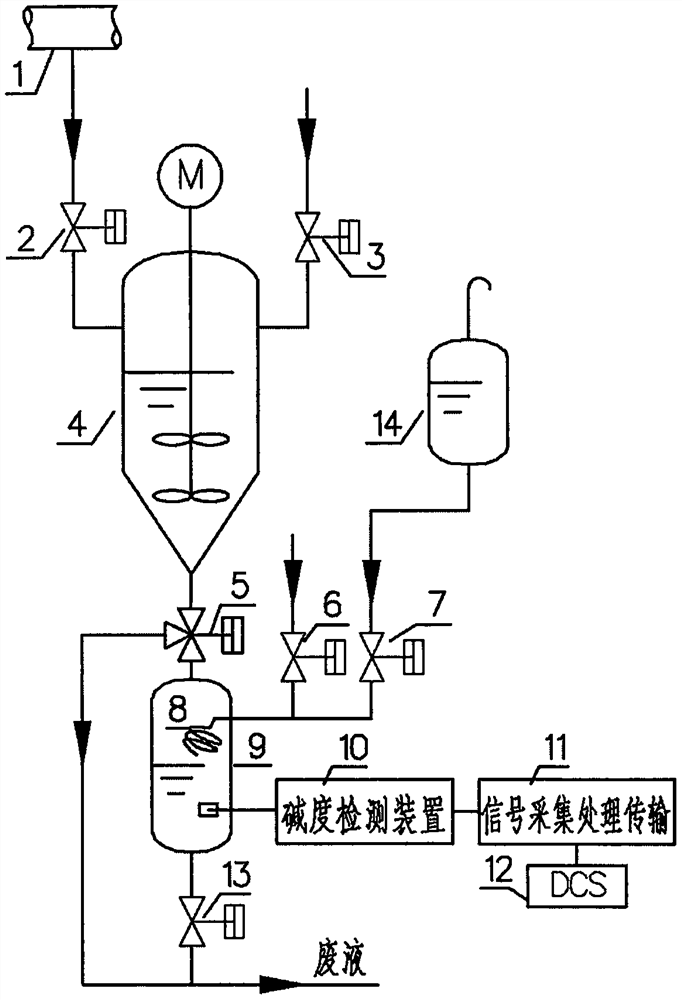

[0028] Such as figure 1 As shown, an online analysis device for preparing the alkalinity of working fluid in hydrogen peroxide by anthraquinone method includes a mixing chamber 4, which is provided with a stirring device and has a conical bottom; the upper part of the mixing chamber 4 is quantitatively fed by working fluid The control valve 2 is connected to the working fluid pipeline 1, and the pure water quantitative control valve 3 is connected to the water source through the mixing chamber; the liquid discharge pipe at the bottom of the mixing chamber 4 is provided with a two-position three-way solenoid valve 5, and one of the three-way solenoid valves drains to waste Pipeline, one discharges liquid to the measurement chamber 9; the upper part of the measurement chamber 9 is provided with a measurement chamber pure water quantitative control valve 6, which is connected in parallel to the buffer liquid tank 14 through the buffer liquid quantitative control valve 7; the inter...

Embodiment 2

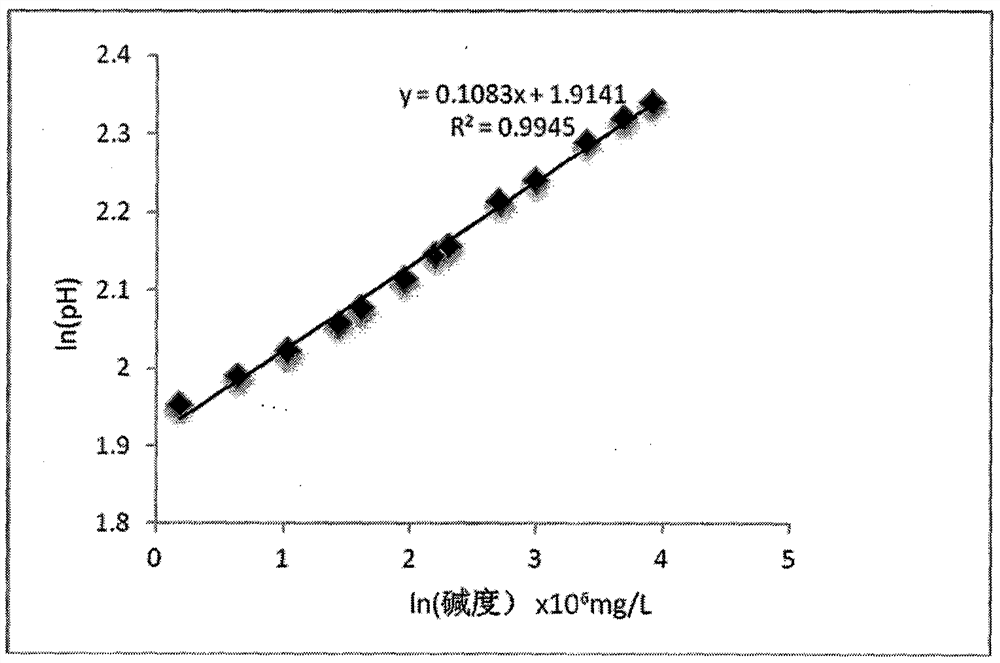

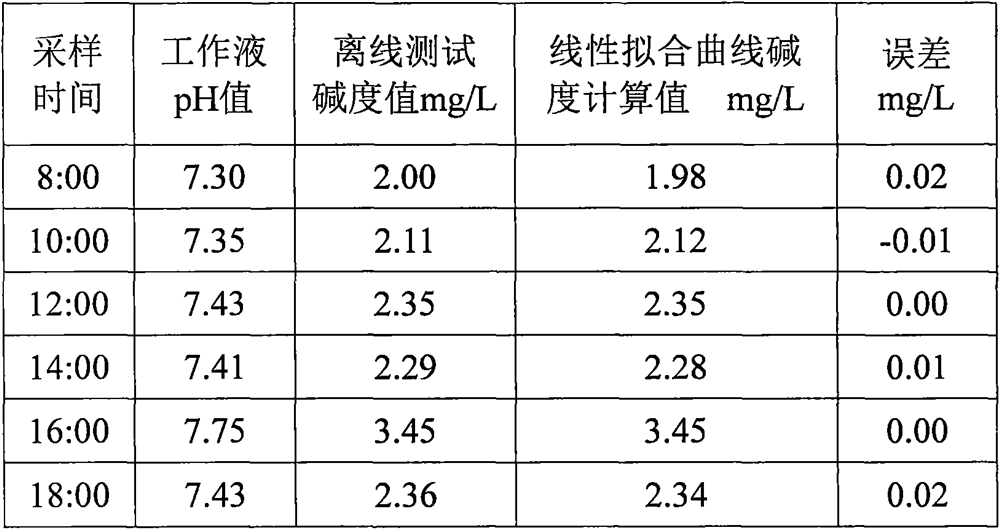

[0037] A certain 100,000 tons / year (27.5%) hydrogen peroxide plant is installed with an online analyzer for the alkalinity of the working fluid, and the alkalinity of the working fluid is measured on-line every 2 hours. Among them, 200mL of working solution and 100mL of pure water were taken each time, stirred for 1min, allowed to stand for 3min to stratify, and the pH value of the aqueous phase after stratification was tested online.

[0038] At the same time, the operator goes to the site to take samples at the same time as the online analyzer every 2 hours. The alkalinity of the samples is measured by the offline method in the laboratory, and the pH value is measured by the on-site alkalinity online analyzer, and the linear fitting curve is used Calculate its alkalinity. The experimental results are shown in Table 1.

[0039] Table 1 Comparison of offline test alkalinity value and linear fitting curve alkalinity calculation value.

[0040] Table 1 Comparison of offline test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com