Efficient intrinsic flame-retardant polycarbonate and preparation method thereof

An intrinsic flame retardant, polycarbonate technology, applied in the field of high-efficiency intrinsic flame retardant polycarbonate and its preparation, can solve the problems of large investment in phosgene method, small amount of sulfonate added, high risk, etc. Overcome uneven dispersion, improve flame retardant properties, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

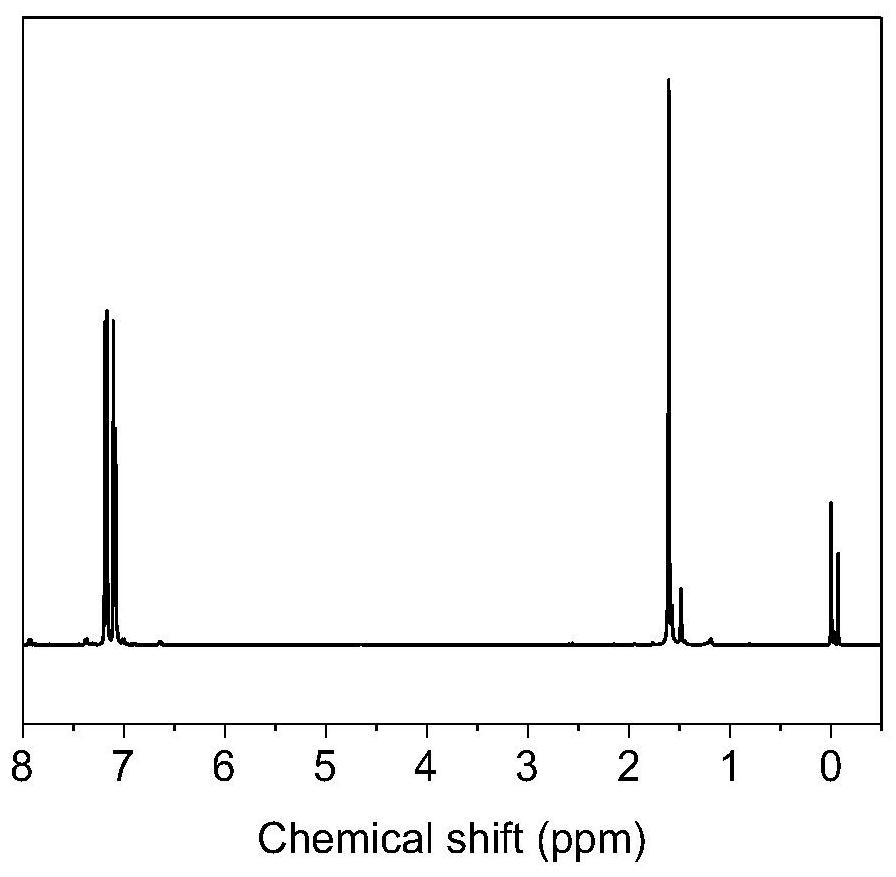

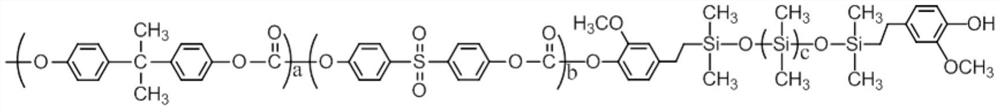

Method used

Image

Examples

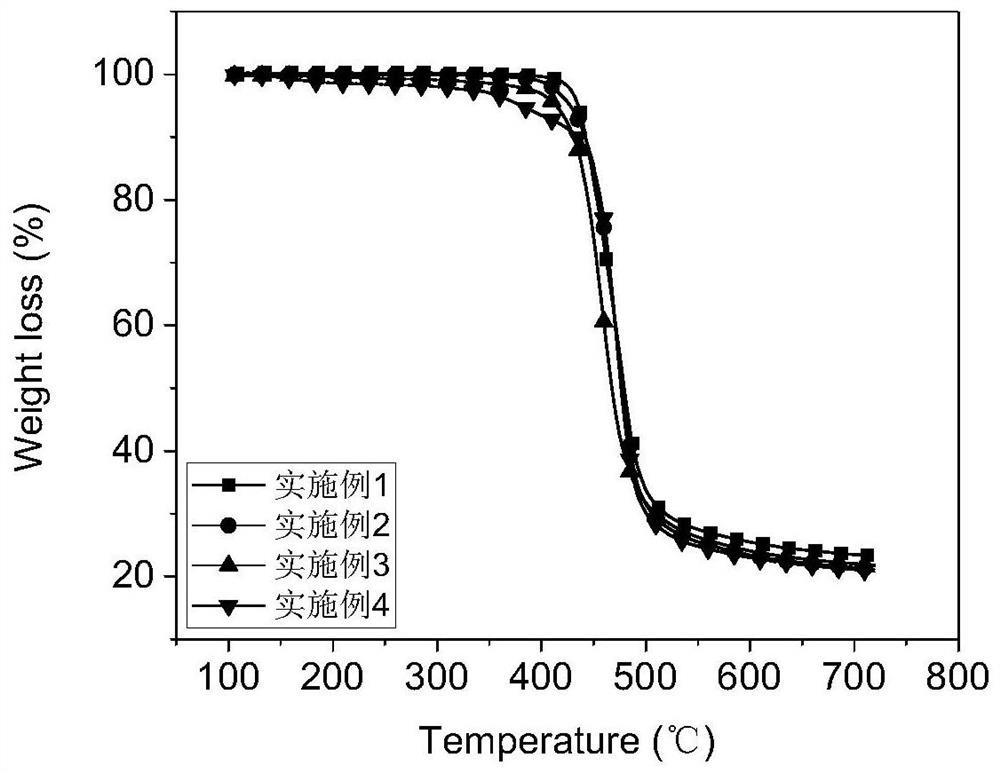

Embodiment 1

[0031] Add 26.54g of bisphenol A and 0.9g of bisphenol S into a 250ml three-necked flask, then add a certain amount of NaOH aqueous solution, and stir to fully dissolve it. Then add 0.22g of triethylamine, 1.65g of siloxane and 0.18g of sodium bisulfite, stir rapidly and raise to 35°C to dissolve completely. Dissolve 13.024g of triphosgene in 160ml of dichloromethane, dropwise add it into a three-neck flask with a constant pressure dropping funnel, and continue to react for 1 hour after the dropwise addition is completed. Let the contents of the three-necked flask stand for 1 hour, pour out the supernatant, wash the lower turbid solution with deionized water until it is neutral, then use 200ml of absolute ethanol to precipitate the product, filter it, and dry it in an oven at 100°C for 12 Hours, the intrinsic flame retardant polycarbonate was obtained.

Embodiment 2

[0033] Add 25.72g of bisphenol A and 1.8g of bisphenol S into a 250ml three-necked flask, then add a certain amount of NaOH aqueous solution, and stir to fully dissolve it. Then add 0.22g triethylamine, 1.65g siloxane and 0.18g sodium bisulfite, stir rapidly and raise to 35°C to dissolve completely. Dissolve 13.024g of triphosgene in 160ml of dichloromethane, dropwise add it into a three-neck flask with a constant pressure dropping funnel, and continue to react for 1 hour after the dropwise addition is completed. Let the contents of the three-necked flask stand for 1 hour, pour out the supernatant, wash the lower turbid solution with deionized water until it is neutral, then use 200ml of absolute ethanol to precipitate the product, filter it, and dry it in an oven at 100°C for 12 Hours, the intrinsic flame retardant polycarbonate was obtained.

Embodiment 3

[0035] Add 24.90 g of bisphenol A and 2.7 g of bisphenol S into a 250 ml three-necked flask, then add a certain amount of NaOH aqueous solution, and stir to fully dissolve it. Then add 0.22g triethylamine, 1.65g siloxane and 0.18g sodium bisulfite, stir rapidly and raise to 35°C to dissolve completely. Dissolve 13.024g of triphosgene in 160ml of dichloromethane, dropwise add it into a three-neck flask with a constant pressure dropping funnel, and continue to react for 1 hour after the dropwise addition is completed. Let the contents of the three-necked flask stand for 1 hour, pour out the supernatant, wash the lower turbid solution with deionized water until it is neutral, then use 200ml of absolute ethanol to precipitate the product, filter it, and dry it in an oven at 100°C for 12 Hours, the intrinsic flame retardant polycarbonate was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com