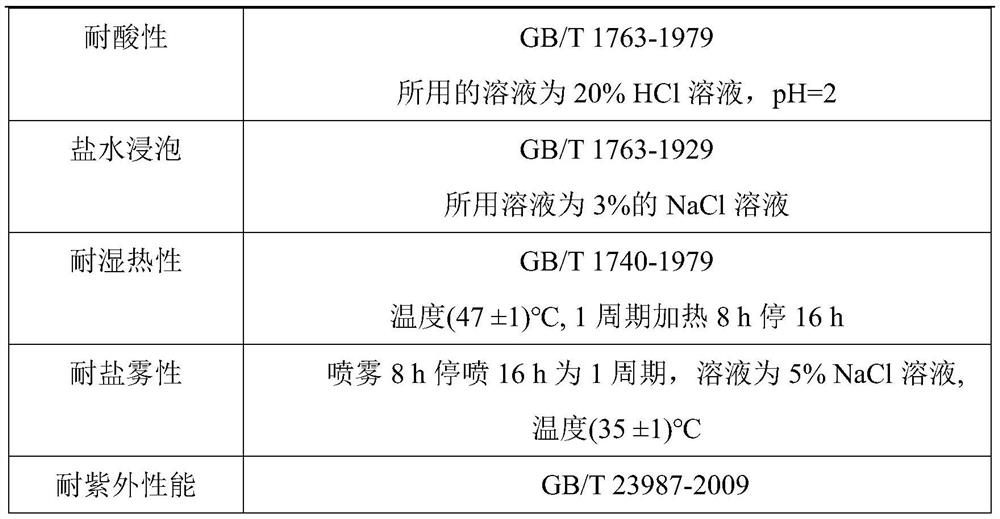

Anti-corrosion epoxy resin coating

A technology of epoxy resin coatings and epoxy resins, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., and can solve the problems of decreased anti-corrosion effect, easy degradation, broken chains, and increased aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

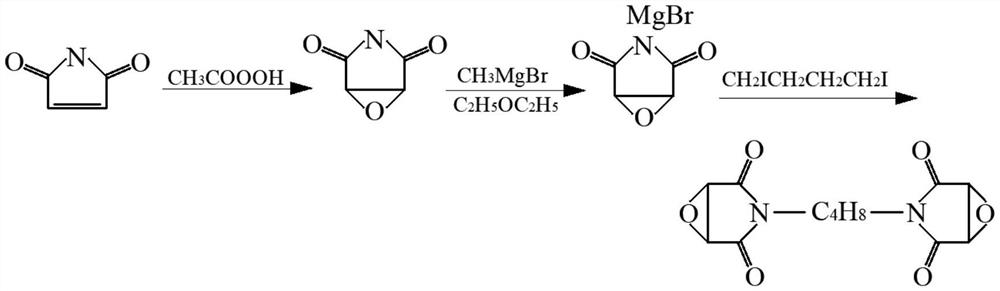

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of polyamide resin containing silicon atoms

[0026] Prepare the polyamide resin as follows:

[0027] Step 1: Add 54.42g glutaramide to 100.00g toluene, heat to 195°C for 15 minutes;

[0028] Step 2: Weigh 158.27g of polydimethylsiloxane (average DP is 100) and 2g of platinum (0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane;

[0029] Step 3: Add 5 g of polydimethylsiloxane dropwise to the reaction mixture;

[0030] Step 4: adding 0.8-1 g of platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane to the reaction mixture;

[0031] Step 5: adding the remaining polydimethylsiloxane dropwise to the reaction mixture;

[0032] Step 6: Add the remaining platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane to the reaction mixture, and continue the reaction for 1 hour, during which stirring is provided;

[0033] Step 7: negative pressure distillation, remove solvent, obtain the polyamide resin with following general structure: Marked as polyamide resin I...

Embodiment 2

[0043] The anti-corrosion epoxy resin coating provided in this embodiment includes component A and component B. In this example, by constructing variables in the formula of component A that constitutes the above-mentioned epoxy resin coating, four treatment groups are set, respectively marked as treatment IA, treatment IIA, treatment IIIA and treatment IVA. Adopt 3 kinds of different epoxy resins respectively as the epoxy resin that is used to prepare component A, to set above-mentioned treatment IA, treatment IIA, treatment IIIA: treatment IA, with the epoxy resin I that makes in the embodiment 1 as For the preparation of the epoxy resin of component A; process IIA, use the epoxy resin II prepared in Example 1 as the epoxy resin for the preparation of component A; process IIIA, use commercially available bisphenol A as the epoxy resin for the preparation of component A; The epoxy resin used to prepare component A; the raw materials used to prepare component A for treatment ⅠA...

Embodiment 3

[0054] The epoxy resin coating that this embodiment provides comprises component A and component B, and wherein, component B is curing agent component, and present embodiment adopts 2 kinds of different materials respectively as component B of epoxy resin coating to set 2 treatment groups. The specific arrangement of each treatment group is as follows: treatment IB, the polyamide resin I prepared in Example 1 was used as component B; treatment IIB, commercially available polyamide 651 was used as component B. The formula composition of component A of each treatment group is exactly the same, and the raw materials used to prepare component A are shown in Table 2. According to Table 2, the required raw materials are fully mixed in proportion to obtain component A. In this embodiment The epoxy resin I prepared in Example 1 is used to prepare the epoxy resin of component A.

[0055] When using the epoxy resin coatings of each treatment group, mix and mix component A and component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com