Axle remanufacturing method, remanufactured axle and system

A remanufacturing and axle technology, applied in coating, metal material coating process, etc., can solve problems such as surface residual stress and surface tissue deterioration, improve product quality and service life, eliminate residual tensile stress, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] In a typical implementation of the present invention, an axle remanufacturing method includes the following content:

[0068] 1) Laser cladding remanufacturing

[0069] Use a lathe to remove scratches on the axle shaft with a depth of 0.2 mm. After removing the scratches, use magnetic particle inspection to confirm whether the removal of the defects is complete.

[0070] The hollow axle to be repaired is clamped on the lathe, specifically clamped by a three-jaw chuck, a semiconductor laser is used to emit laser light, and laser cladding is carried out on the position of the axle to be repaired by coaxial powder feeding. Specifically, iron-based powder can be selected As filler material for laser cladding of axles.

[0071] Laser cladding process parameters are: laser power 2-2.5kw; spot diameter 3mm; scanning speed: 8-10mm / s; lapping amount: 50%; distance between nozzle and workpiece: 10-15mm. Laser cladding is carried out according to the above process parameters. Th...

Embodiment 2

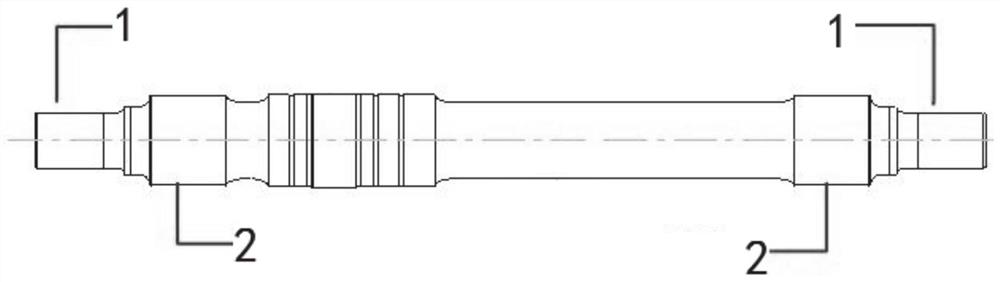

[0103] This embodiment provides a remanufactured axle, which is manufactured through the axle remanufacturing method described in Embodiment 1.

Embodiment 3

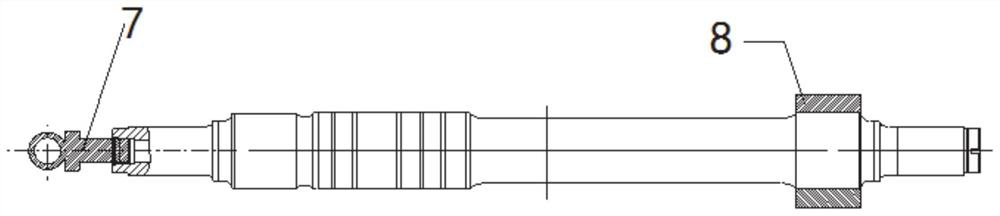

[0105] This embodiment provides a processing system for remanufacturing an axle, including:

[0106] Lathe, which can realize the removal of the scratch defect of the axle, and can realize the rough machining of the axle, and there can be multiple lathes;

[0107] Laser cladding equipment, used for laser cladding on the axle, the laser cladding equipment can be installed on the lathe;

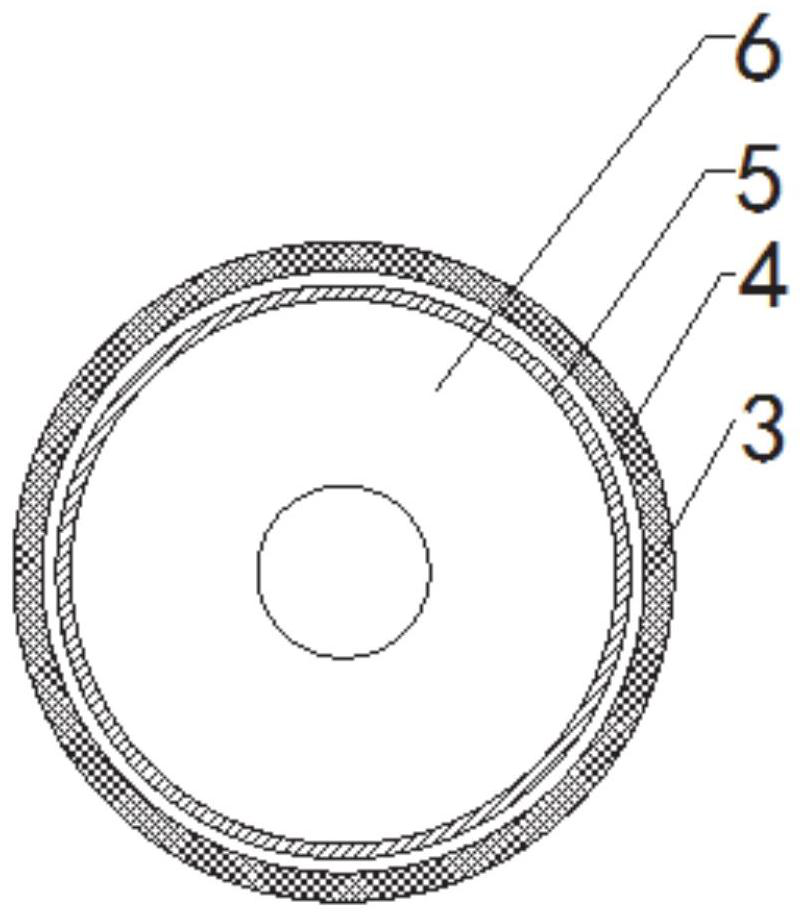

[0108] The package kit, which can be wrapped on the axle completed by laser cladding, is used to insulate the area where the laser cladding layer of the axle is set to the center of the axle;

[0109] The laser shock strengthening equipment is used to carry out laser shock strengthening on the rough-machined axle. The laser shock head is clamped by the manipulator of the robot, and the robot is set on the side of the lathe.

[0110] Of course, the processing system also includes a kerosene tank, which can cool down the axle after the first wrapping and heat preservation.

[0111] In addition,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com