Low-noise air purifier with stable efficiency

An air purifier and stable technology, applied in chemical instruments and methods, gas treatment, air conditioning systems, etc., can solve the problems of reduced purification efficiency and increased noise, and achieve the effect of reducing dust content, increasing air humidity, and good dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

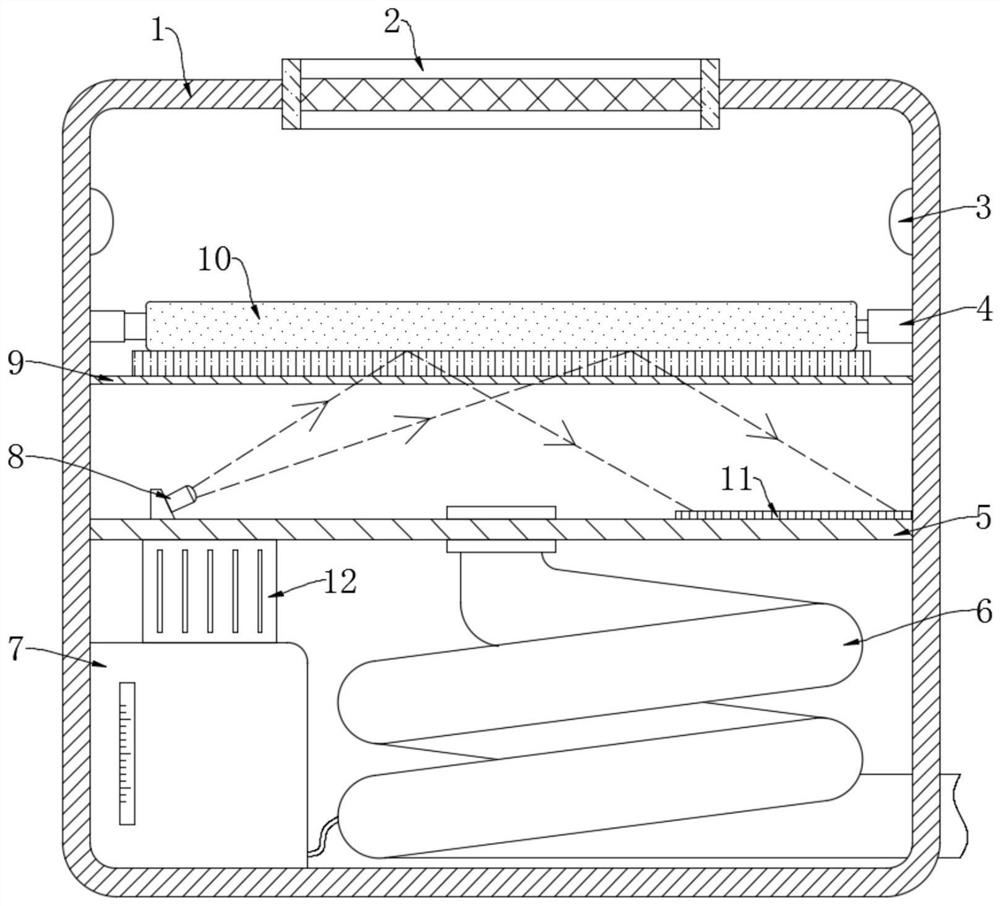

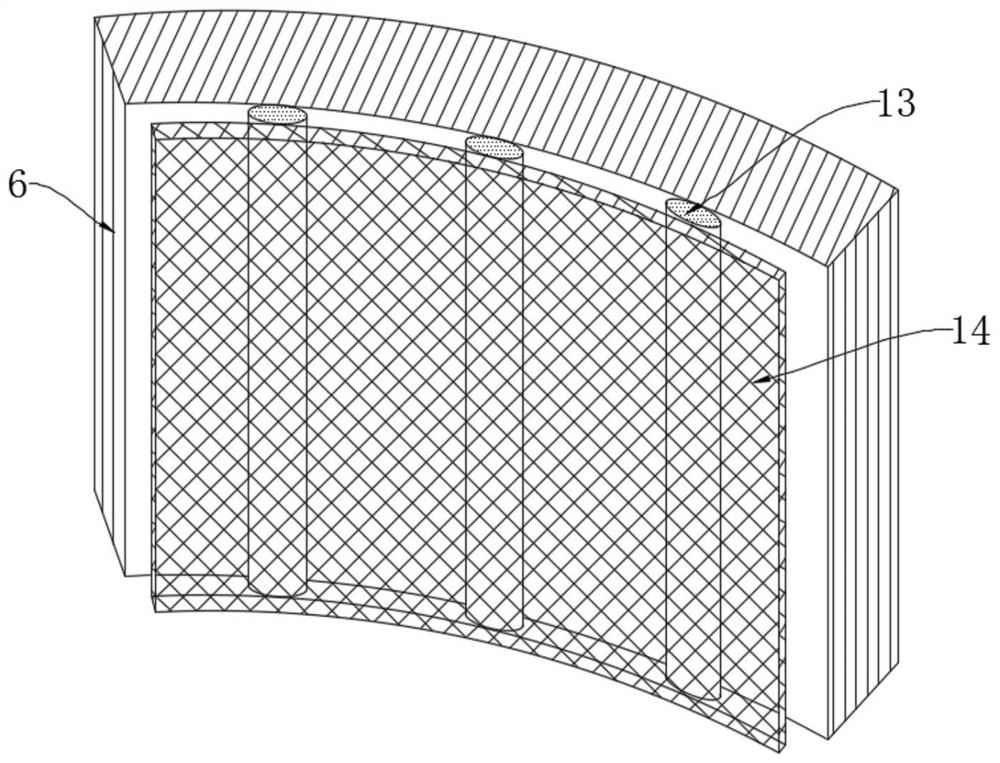

[0025] refer to Figure 1-2 , a low-noise air purifier with stable efficiency, including a housing 1, an air outlet 2 is opened on the top of the housing 1, and a detachable filter screen is installed in the air outlet 2, and the inner wall of the housing 1 is installed with A plurality of ultraviolet lamps 3, a purification mechanism, a detection mechanism and a dust collection mechanism are sequentially provided in the housing 1 from top to bottom, the purification mechanism includes a micro motor 4, a flexible brush 9 and a purification cylinder 10, and the outer surface of the purification cylinder 10 is coated with There is a photocatalyst medium layer, one end of the purification cylinder 10 is rotatably connected to the inner side wall of the housing 1, the other end of the purification cylinder 10 is fixedly connected to the output shaft of the micro motor 4, and the micro motor 4 is fixed to the inner side wall of the housing 1, The micro-motor 4 is a servo motor, and...

Embodiment 2

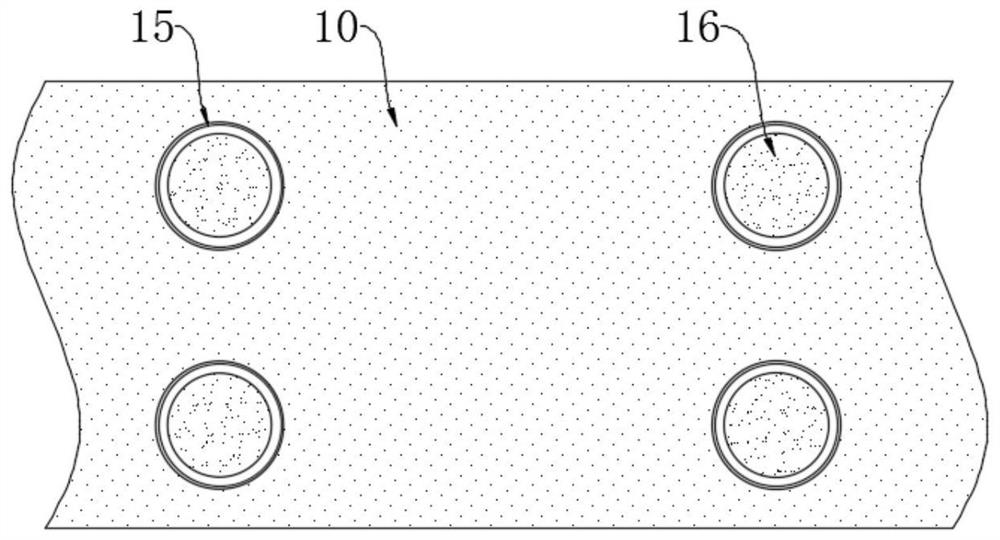

[0035] refer to image 3 , The difference between this embodiment and Embodiment 1 is that a plurality of rotating grooves 15 are symmetrically opened on the purification cylinder 10, and a purification ball 16 is installed in rotation in each rotating groove 15.

[0036] This embodiment can illustrate its functional principle by the following operation mode: the surface of the purification ball 16 is also plated with a photocatalyst medium layer, without increasing the length of the purification cylinder 10 or the specification of the purifier, the surface area of the photocatalyst medium layer can be greatly increased, Thereby improve the purification efficiency, when the micro motor 4 drives the purification cylinder 10 to rotate, the purification ball 16 will rotate under the frictional force, and the rotation groove 15 can also play a certain cleaning effect on the purification ball 16, improving the cleaning effect.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap