Composite substrate material and preparation method thereof, and quantitative detection method of plasticizer in Baijiu

A composite substrate and plasticizer technology, applied in the field of detection, can solve the problems of cumbersome processing, no specific identification and capture function of plasticizer molecules, poor stability, etc., to ensure detection accuracy, enrich SERS hot spots, and increase stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

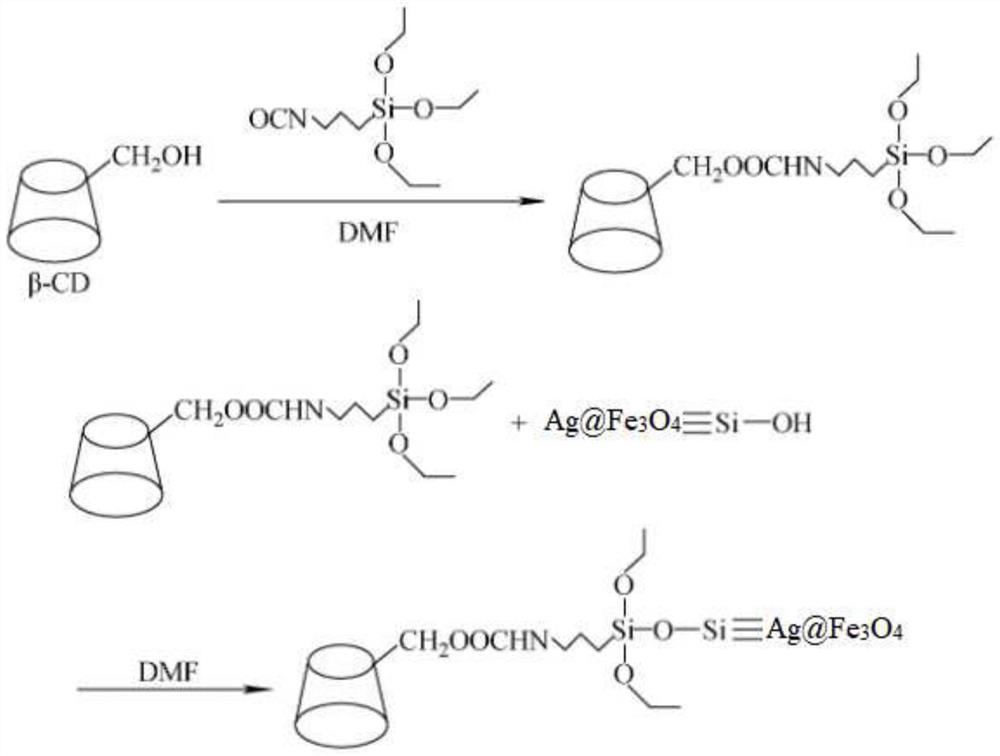

[0040] Embodiment 1 of the present invention provides a kind of composite base material, and its preparation method comprises the following steps:

[0041] S1, add ferric nitrate nonahydrate, silver nitrate, and anhydrous sodium acetate into 100mL of ethylene glycol at a ratio of 4mmoL: 1mmol: 40mmol, then add 1.0g of polyvinylpyrrolidone, and magnetically stir for 4h to obtain a mixed solution. Then, The mixed solution was placed in a hydrothermal reaction kettle and subjected to a hydrothermal reaction at 200°C for 12 hours; after the reaction was completed, it was cooled to room temperature, filtered, washed and dried in vacuum to obtain Ag@Fe with a core-shell structure. 3 o 4 Composite nanoparticles;

[0042] S2, 0.3g of the Ag@Fe 3 o 4 The composite nanoparticles were dispersed in 50 mL of cetyltrimethylammonium bromide solution with a concentration of 1 mmol / L, and then 15 mL of absolute ethanol and 0.8 mL of amphiphilic polymer L- Cysteine solution, 50 mL of sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com