Zn-doped VO2 powder and method for preparing composite film by using powder

A composite film, VO2 technology, applied in the direction of vanadium oxide, coating, etc., can solve the problem of visible light transmittance reduction, etc., to achieve good heat-induced phase change visible light anti-reflection, good intelligent dimming function, visible light transmittance increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

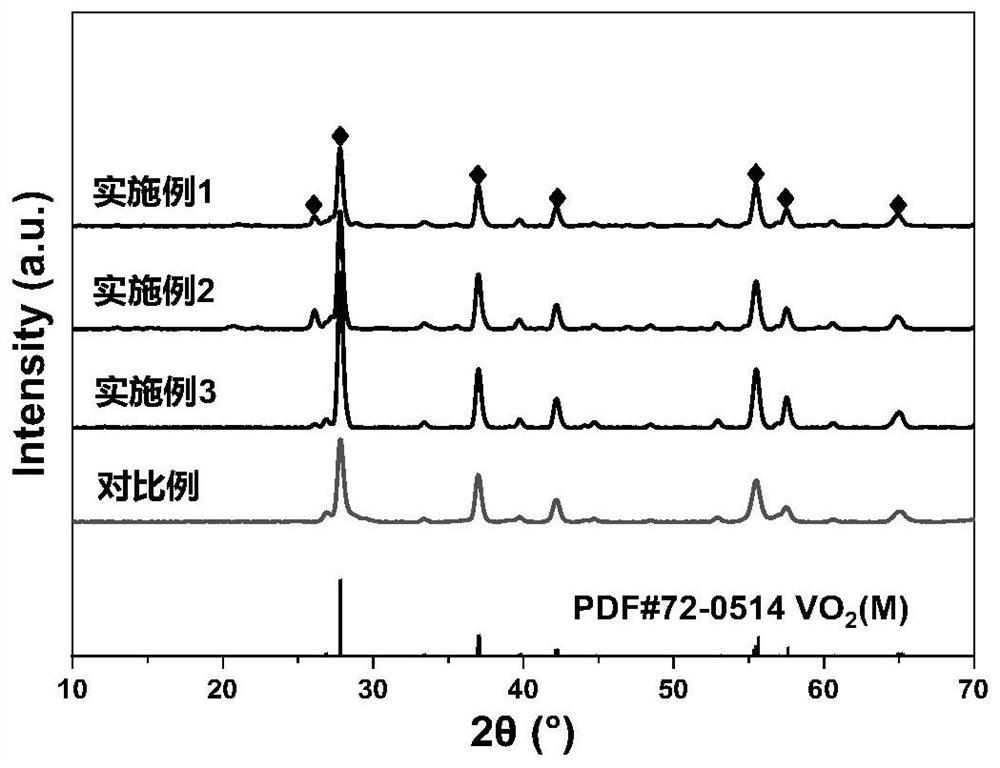

[0049] (1)Zn 0.16 VO 2 Powder preparation: Disperse 3.64g of vanadium pentoxide and 5.0428g of oxalic acid dihydrate in 100mL of deionized water, add 1.4048g of zinc acetate dihydrate to obtain a reaction precursor; react the reaction precursor at 240°C for 10 hours, and The reacted precipitate was washed with water and alcohol in turn, vacuum filtered, and dried at 60°C for 12 hours; then placed in N 2 After heat treatment at 680°C for 3 hours under protection, Zn 0.16 VO 2 Powder.

[0050] (2)Zn 0.16 VO 2 Film preparation: take 0.4g Zn 0.16 VO 2 Powder, add 10mL of absolute ethanol, after ball milling dispersion treatment, extract 5mL of ball milling liquid, 20mL of absolute ethanol, 12.5mL of polyurethane resin and mix and stir for 20min to obtain a coating solution, and use the roller coating method to evenly coat the coating solution on the glass substrate surface, thus obtaining Zn 0.16 VO 2 film.

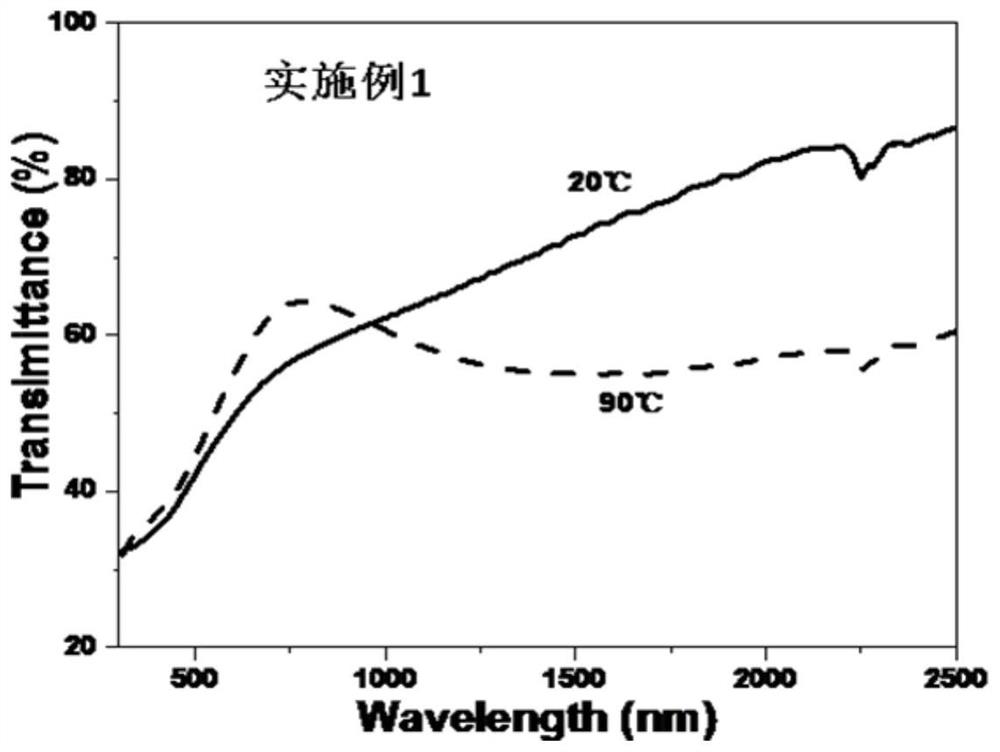

[0051] Test result shows, the Zn prepared by above-mentioned ...

Embodiment 2

[0053] (1)Zn 0.08 VO 2 Powder preparation: Disperse 3.64g of vanadium pentoxide and 5.0428g of oxalic acid dihydrate in 100mL of deionized water, add 0.7024g of zinc acetate dihydrate to obtain a reaction precursor; react the reaction precursor at 240°C for 10 hours, The precipitate after the reaction was washed with water and alcohol in sequence, vacuum filtered, and dried at 60°C for 12 hours; then placed in N 2 After heat treatment at 680°C for 3 hours under protection, Zn 0.08 VO 2 Powder.

[0054] (2)Zn 0.08 VO 2 Film preparation: Take 0.4g Zn 0.08 VO 2 Powder, add 10mL of absolute ethanol, after ball milling dispersion treatment, extract 5mL of ball milling liquid, 20mL of absolute ethanol, 12.5mL of polyurethane and mix and stir for 20min to obtain a coating solution, and use the roller coating method to evenly coat the coating solution on the carrier surface of the glass slide, thus obtaining Zn 0.08 VO 2 Composite film.

[0055] Test result shows, the Zn pr...

Embodiment 3

[0057] (1)Zn 0.02 VO 2 Powder preparation: Disperse 3.64g of vanadium pentoxide and 5.0428g of oxalic acid dihydrate in 100mL of deionized water, add 0.1756g of zinc acetate dihydrate to obtain a reaction precursor; react the reaction precursor at 240°C for 10 hours, The precipitate after the reaction was washed with water and alcohol in sequence, vacuum filtered, and dried at 60°C for 12 hours; then placed in N 2 After heat treatment at 680 °C for 3 h under protection, Zn-doped VO 2 Powder.

[0058] (2)Zn 0.02 VO 2 Film preparation: same as step (2) in Example 1.

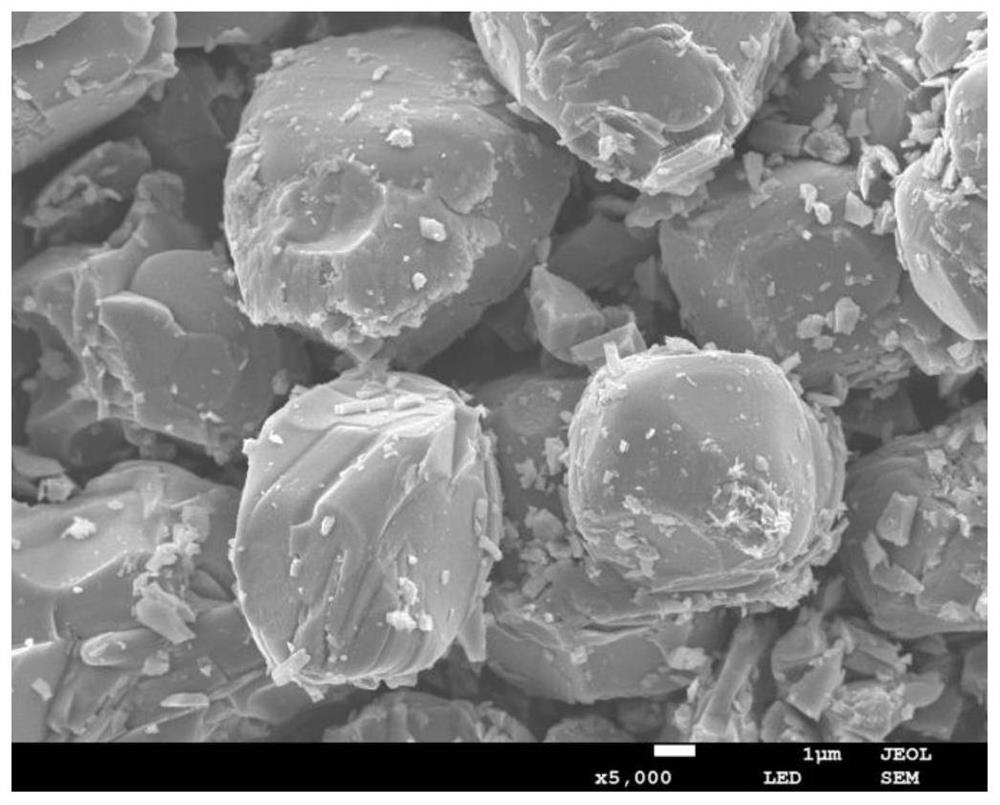

[0059]Test result shows, the Zn prepared by above-mentioned method 0.02 VO 2 The crystal phase structure of the powder is M phase VO 2 , the particles are approximately spherical large particles with a rough surface and a diameter of 5-10 μm, and some small particles are attached to the surface of the large spherical particles, Zn 0.08 VO 2 The powder is composed of M phase VO 2 Converted to R-phase VO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com