Inorganic ceramic membrane support material and preparation method thereof

An inorganic ceramic membrane and support technology, which is applied in ceramic products, chemical instruments and methods, membrane technology, etc., can solve the problems of high cost, high sintering temperature, and permeability of ceramic membranes that need to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

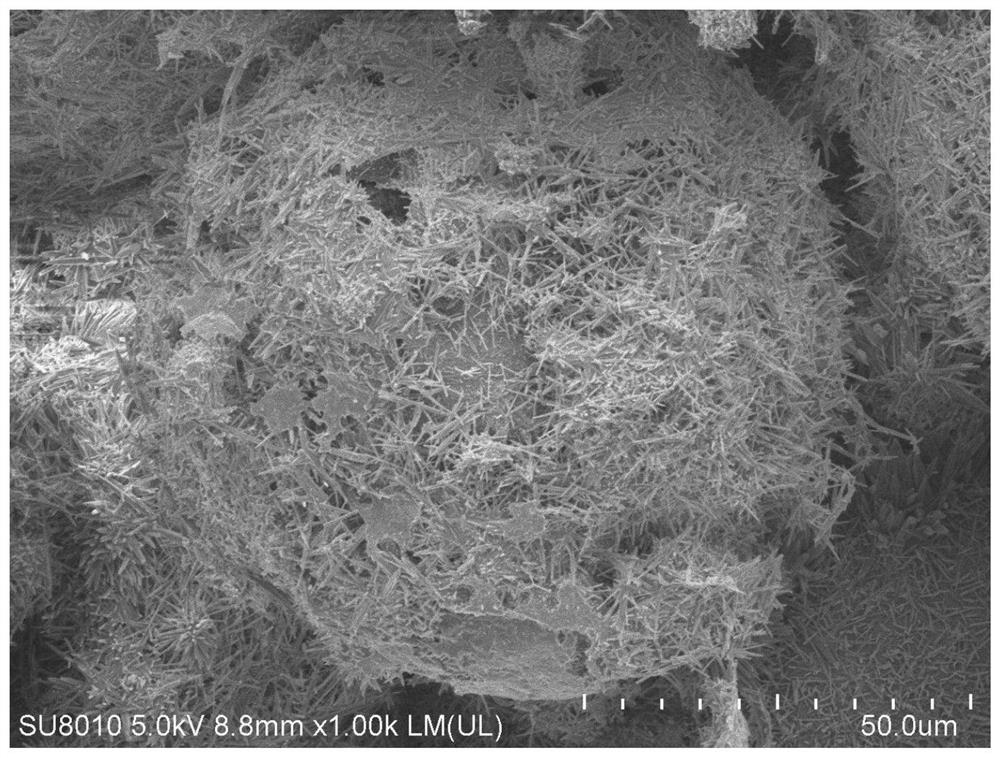

[0027] Example 1 Mono-like fiber inlet forming spherical shape particle inorganic ceramic membrane material formed by open air holes

[0028] (1) 50 g of charcoal powder is placed in a pellet, and the spray concentration is 10 ml of a concentration of 5% PVA solution, and the balloon is started to obtain a charcoal powder ball of different particle sizes;

[0029] (2) According to the weight parts: 35 parts of the desert, 65 parts of aluminum hydroxide, 4 different vanadium dioxide, 3 of the aluminum fluoride, and mix the above raw materials.

[0030] (3) Place the core 20g made in 1 in the disc, 4 ml of the PVA solution having a concentration of 5%, and continuously stir, followed by a powder 20g of the medium mixing, and continuously stirred, Get mullite precursor pseudo-spherical particles;

[0031] (4) The pseudo-spherical particles prepared 3 were warmed by room temperature to 400 ° C for 60 min, and at the highest temperature insulation for 60 min, then rose to 1200 ~ 1350 °...

Embodiment 2

[0034] Example 2 Mono-like fiber inlet having an open air hole is formed of spherical shape particle inorganic ceramic membrane material

[0035] (1) 50 g of charcoal powder is placed in a pellet, and the spray concentration is 10 ml of a concentration of 5% PVA solution, and the balloon is started to obtain a charcoal powder ball of different particle sizes;

[0036] (2) According to the weight of the material: 45 parts of the desert, 55 parts of aluminum hydroxide, 4 different vanadium dioxide, 3 of the fluorinated aluminum, and mix the above raw materials well;

[0037] (3) Place the core 20g made in 1 in the disc, 4 ml of the PVA solution having a concentration of 5%, and continuously stir, followed by a powder 20g of the medium mixing, and continuously stirred, Get mullite precursor pseudo-spherical particles;

[0038] (4) The pseudo-spherical particles prepared 3 were warmed by room temperature to 400 ° C for 60 min, and at the highest temperature insulation for 60 min, then...

Embodiment 3

[0041] Example 3 Mono-like fiber inlet having open air holes, type spherical shape particle inorganic ceramic membrane material

[0042] (1) 50 g of charcoal powder is placed in a pellet, and the spray concentration is 10 ml of a concentration of 5% PVA solution, and the balloon is started to obtain a charcoal powder ball of different particle sizes;

[0043] (2) According to the weight of the material: 55 parts of the desert, 45 parts of aluminum hydroxide, 4 different vanadium dioxide, 3 of the aluminum fluoride, and mix the above raw materials well;

[0044] (3) Place the core 20g made in 1 in the disc, 4 ml of the PVA solution having a concentration of 5%, and continuously stir, followed by a powder 20g of the medium mixing, and continuously stirred, Get mullite precursor pseudo-spherical particles;

[0045] (4) The pseudo-spherical particles prepared 3 were warmed by room temperature to 400 ° C for 60 min, and at the highest temperature insulation for 60 min, then rose to 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com