Method for producing collagen peptide from fish scales under assistance of subcritical water extraction and application of collagen peptide

A technology of fish collagen peptide and fish collagen, which is applied in the field of subcritical water extraction to assist fish scales to produce collagen peptide, can solve the problems of low industrialization profit and low added value of gelatin products, achieve wide application, shorten the preparation cycle, extract high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

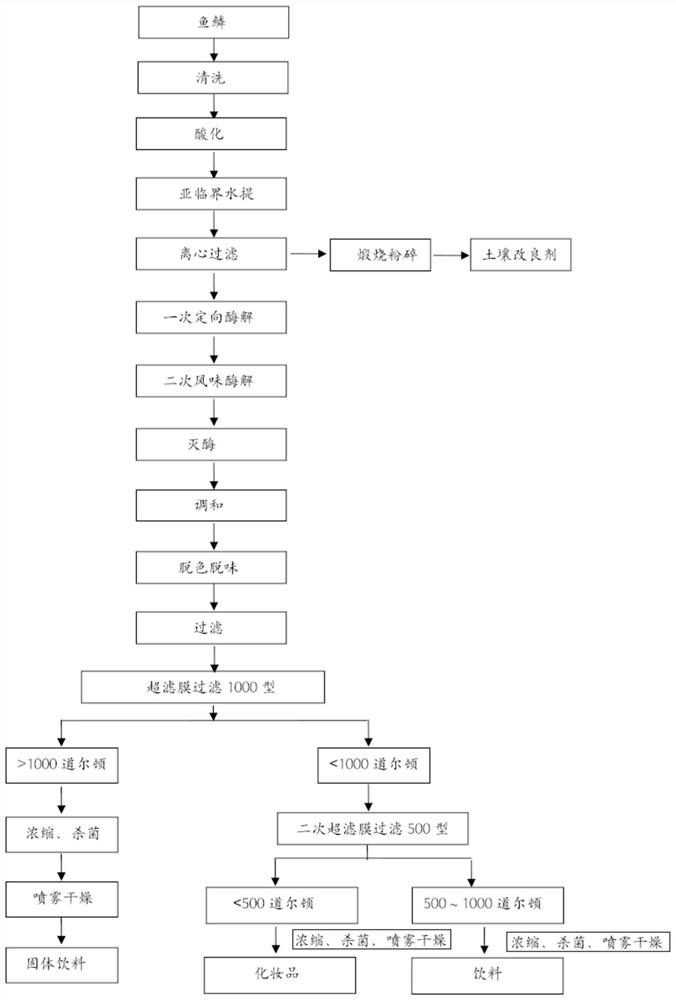

[0069] The present disclosure provides a method for subcritical water extraction to assist fish scales to produce collagen peptides, including:

[0070] 1. Fish scale cleaning: Take 1kg of dried fish scales, pour it into 2% citric acid solution, 9kg of 2% citric acid solution, bubbling and cleaning at room temperature for 1 hour, and then lift it into a food-grade plastic bucket through a stainless steel filter hoist. Water once and drain to get clean fish scales;

[0071] 2. Acidification: acidify the above-mentioned clean fish scales with 10% citric acid solution 10kg, heat up to 90°C, and stir for 0.5h to obtain acidified fish scales;

[0072] 3. Subcritical extraction: put the high-temperature acidified fish scales into the autoclave through the elevator, raise the temperature to 170℃, keep the pressure in the autoclave at 1.0MPa, keep stirring for 60min, cool down to 50-60℃, and let the extract pass through the rotary table. In the material tank of the disc centrifuge, c...

Embodiment 2

[0087] The present disclosure provides a method for subcritical water extraction to assist fish scales to produce collagen peptides, including:

[0088] 1. Fish scale cleaning: Take 1kg of dried fish scales, pour it into 5% citric acid solution, 9kg of 5% citric acid solution, bubbling and cleaning at room temperature for 1 hour, and then lift it into a food-grade plastic bucket through a stainless steel filter screen elevator. Water once, drain to get clean fish scales;

[0089] 2. Acidification: acidify the above-mentioned clean fish scales with 10% citric acid solution 10kg, heat up to 90°C, and stir for 0.5h to obtain acidified fish scales;

[0090] 3. Subcritical extraction: put the high-temperature acidified fish scales into the autoclave through the hoist, raise the temperature to 160°C, and keep the three. Subcritical extraction: put the high-temperature acidified fish scales into the autoclave through the hoist, raise the temperature to 160°C, and keep the autoclave ...

Embodiment 3

[0105] The present disclosure provides a method for subcritical water extraction to assist fish scales to produce collagen peptides, including:

[0106] 1. Fish scale cleaning: Take 1kg of dried fish scales, pour it into 2% citric acid solution, 9kg of 2% citric acid solution, bubbling and cleaning at room temperature for 1 hour, and then lift it into a food-grade plastic bucket through a stainless steel filter hoist. Water once and drain to get clean fish scales;

[0107] 2. Acidification: acidify the above-mentioned clean fish scales with 10kg of 20% citric acid solution, heat up to 90°C, and stir for 0.5h to obtain acidified fish scales;

[0108] 3. Subcritical extraction: put the high-temperature acidified fish scales into the autoclave through the elevator, raise the temperature to 155℃, keep the pressure in the autoclave at 1.0MPa, keep stirring for 60min, cool down to 55℃, and let the extract pass through the disc of the rotating turntable In the material tank of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com