A method and device for the separation of hydrocarbon cracking gas and the production of ethylbenzene

A technology for cracking gas and ethylbenzene, which can be used in the purification/separation of hydrocarbons, ethylene production, chemical instruments and methods, etc., and can solve problems such as poor anti-fluctuation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

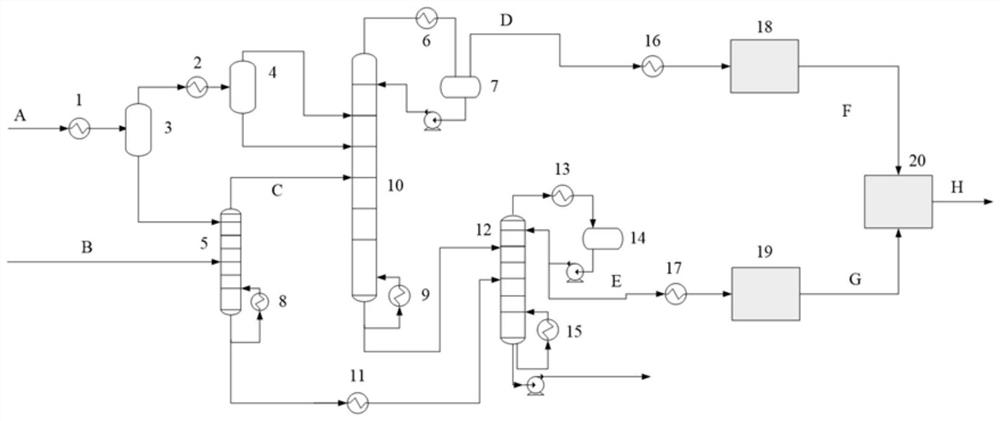

[0027] Taking a certain hydrocarbon catalytic cracking device as an example, adopt the device and method of the present invention, wherein, the pre-demethanizer precooler, the pre-demethanizer feed tank, the demethanizer pre-cooler, the demethanizer feed tank, Multiple ethylene-containing dry air cooling recoverers and ethylene-ethane air cooling recoverers can be set up according to requirements. In this embodiment, the above-mentioned equipment is all one, and the process is shown in figure 1 .

[0028] The gas-phase hydrocarbon cracking gas A and the liquid-phase hydrocarbon cracking gas B that have been treated by upstream impurity removal enter the fuzzy separation unit provided by the present invention. The flow rate of A is 40.2t / h, the temperature is 10°C, and the pressure is 3.32MPaG. The flow rate is 33.8t / h, the temperature is 10°C, and the pressure is 3.32MPaG. The composition is shown in Table 1 and Table 2 respectively. The gas-phase cracked gas A is pre-cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com