Chemical-corrosion-resistant insulating material and preparation method thereof

A technology of chemical corrosion resistance and insulating materials, which is applied in the field of composite material processing, can solve the problems of affecting the comprehensive performance of materials, corrosion resistance and lower mechanical properties, etc., and achieve good safety performance, improve mechanical properties, and excellent chemical corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the insulating material comprises the steps of:

[0032] The first step is to add chloroprene rubber and natural rubber into the internal mixer under the condition that the initial temperature of the mixing room is 50-60°C and the rotor speed is 80-90r / min. Strong agent and coupling agent, mixed for 8-10 minutes, and then discharged; the discharged rubber was put into the open mill for re-milling, and accelerators and vulcanizing agents were added, and then knives, thin passes, and triangular bags were mixed. After refining evenly, increase the roller distance to 2mm, and discharge the sheet to obtain the mixed rubber;

[0033] The second step is to mix the rubber compound, modified low-density polyethylene, reinforcing filler, and ammonium polyphosphate and then add it to the torque rheometer. The melting temperature is 100-105°C, and the screw speed is 60-70r / min. , the blending time is 25-28min; then take out the mixture, put it into a flat...

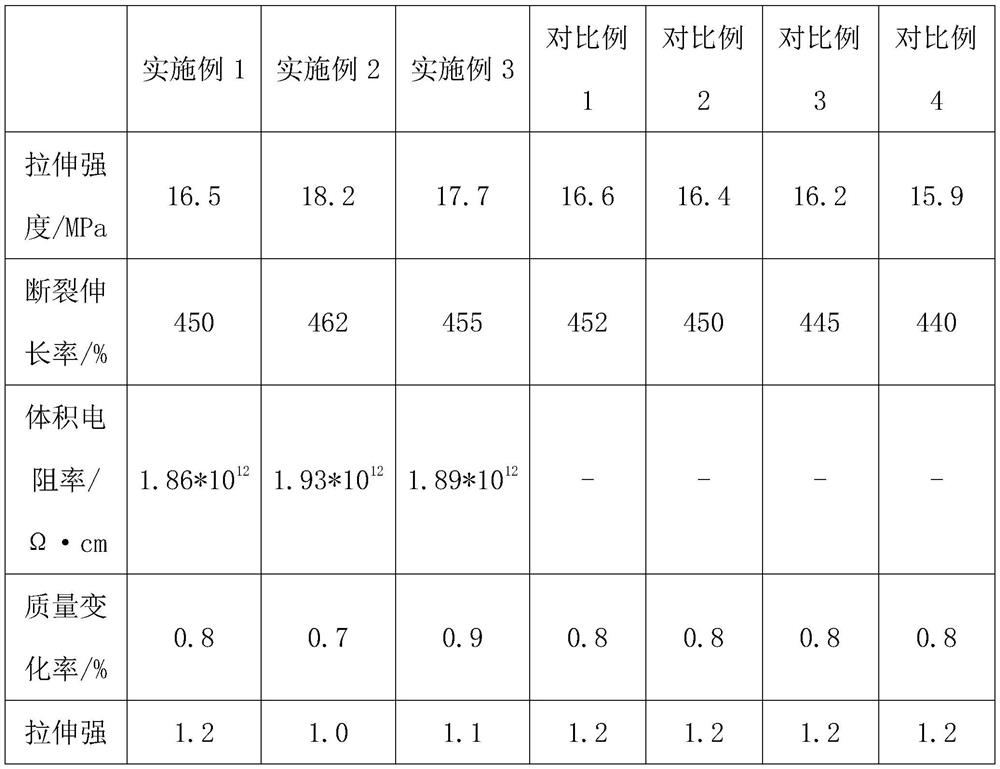

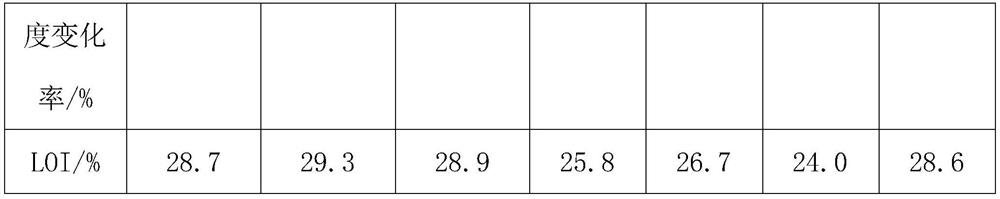

Embodiment 1

[0051] A chemical-resistant insulating material, comprising the following raw materials in parts by weight: 60 parts of modified low-density polyethylene, 14 parts of chloroprene rubber, 4 parts of natural rubber, 0.05 parts of accelerator, 0.2 parts of reinforcing agent, and 0.02 parts of vulcanizing agent 0.03 parts of coupling agent, 9 parts of flame retardant, 2 parts of ammonium polyphosphate, 3 parts of reinforcing filler;

[0052] The insulating material is made by the following steps:

[0053] The first step is to add neoprene and natural rubber into the internal mixer under the condition that the initial temperature of the mixing room is 50°C and the rotor speed is 80r / min. After 2 minutes, the reinforcing agent and coupling agent are added in sequence. , mixed for 8 minutes, and deglued; the discharged rubber material was put into the open mill for re-milling, and accelerators and vulcanizing agents were added, and knives, thin passes, and triangular bags were mixed....

Embodiment 2

[0056] A chemical-resistant insulating material, comprising the following raw materials in parts by weight: 65 parts of modified low-density polyethylene, 15 parts of neoprene, 4.5 parts of natural rubber, 0.055 parts of accelerator, 0.25 parts of reinforcing agent, and 0.025 parts of vulcanizing agent 0.035 parts of coupling agent, 11.5 parts of flame retardant, 2.5 parts of ammonium polyphosphate, 3.5 parts of reinforcing filler;

[0057] The insulating material is made by the following steps:

[0058] The first step is to add chloroprene rubber and natural rubber into the internal mixer under the condition that the initial temperature of the mixing room is 55°C and the rotor speed is 85r / min. After 2.5 minutes, add the reinforcing agent and coupling Adding agent, mixing for 9 minutes, deglue; the discharged rubber material is put into the open mill for re-milling, and the accelerator and vulcanizing agent are added, and the knives, thin pass, and triangular bag mixing are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com