Terahertz converter

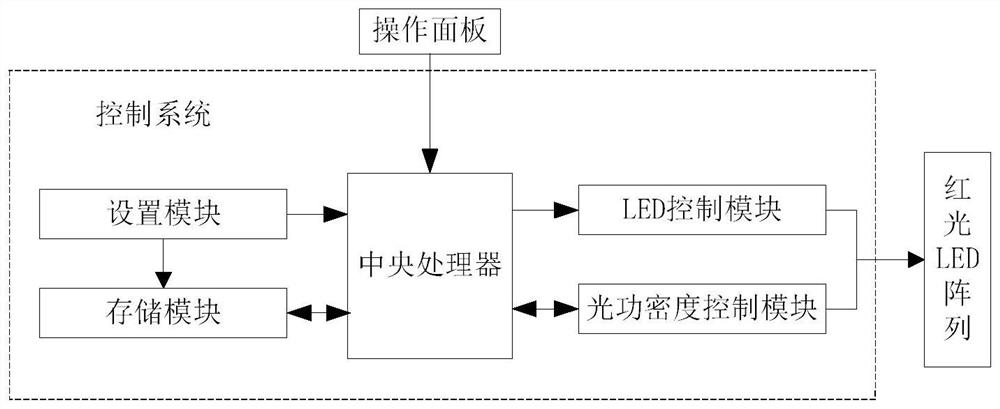

A converter and terahertz technology, applied in the field of terahertz converters, can solve the problem of less market application, and achieve the effects of accelerating water metabolism, improving taste, and promoting health and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

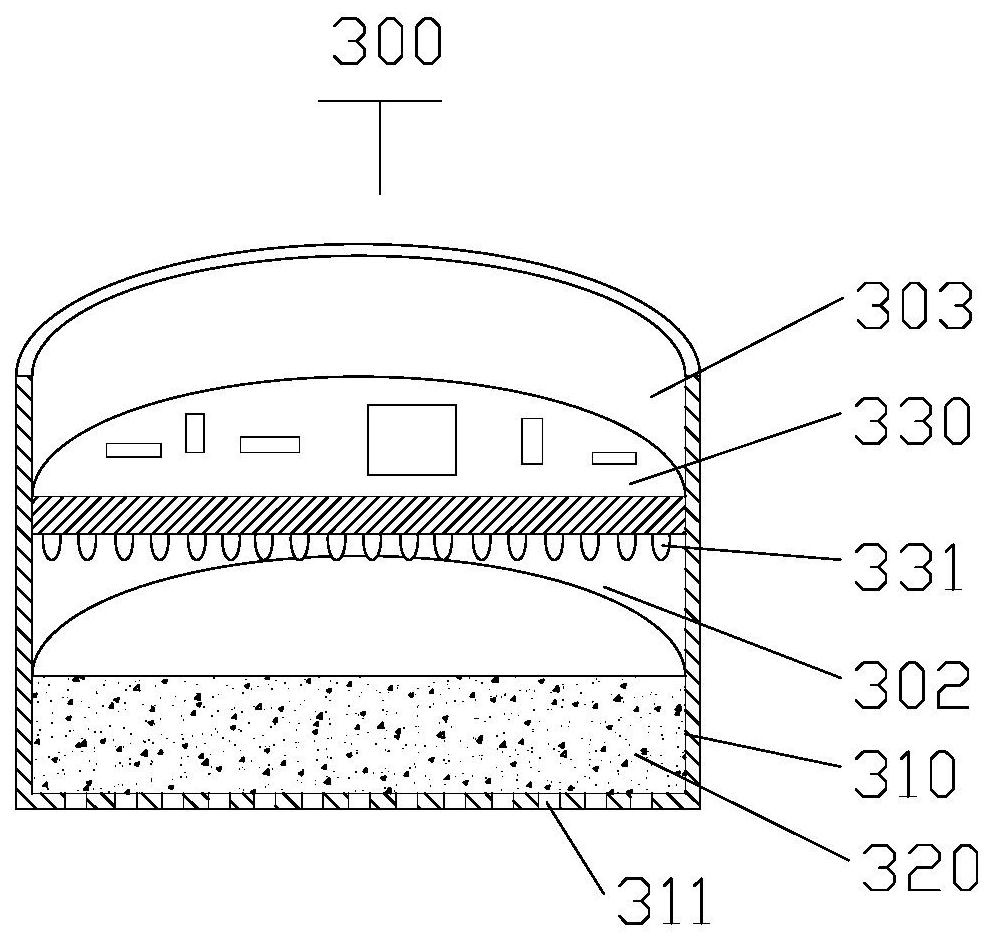

Embodiment 1

[0067] Put 20g of quartz, 11g of polyvinylpyrrolidone, 15g of polyethylene terephthalate, and 10g of polymethyl methacrylate in a container jar, and stir at 60°C for 60 minutes to prepare a slurry; among them, the quartz particles The particle size is 10nm;

[0068] Cool the slurry to normal temperature, add 8g of carbon nanotubes and continue stirring for 15 minutes to prepare the precursor slurry;

[0069] Add 23g of epoxy resin and 13g of curing agent to the precursor slurry in turn, and continue to stir for 20 minutes to obtain a polymer slurry;

[0070] The polymer slurry was injected into a mold to produce a polymer with a thickness of 15 mm and a diameter of 40 mm. This polymer is suitable for irradiation with red light with a wavelength of 605-630nm.

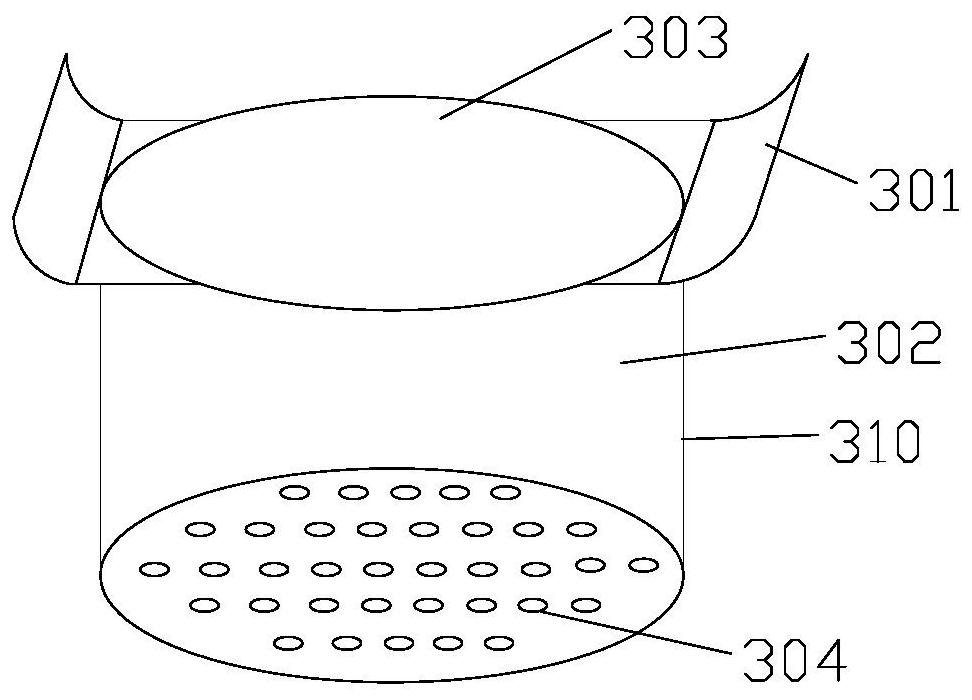

[0071] When preparing the terahertz converter, the diameter of the exit hole 301 at the bottom of the cup-shaped housing 310 is 2 mm.

Embodiment 2

[0073] Put 11g of quartz, 8g of polyvinylpyrrolidone, 10g of polyethylene terephthalate, and 6g of polymethyl methacrylate in a container jar, and stir at 40°C for 30 minutes to prepare a slurry; among them, the quartz particles The particle size is 60nm;

[0074] Cool the slurry to normal temperature, add 20g of carbon nanotubes and continue stirring for 30 minutes to prepare the precursor slurry;

[0075] Add 40g of epoxy resin and 21g of curing agent to the precursor slurry in turn, and continue to stir for 50 minutes to obtain polymer slurry;

[0076] The polymer slurry was injected into a mold to produce a polymer with a thickness of 20 mm and a diameter of 50 mm. This polymer is suitable for irradiation with red light with a wavelength of 631-700nm.

[0077] When preparing the terahertz converter, the exit hole 301 at the bottom of the cup-shaped housing 310 has a diameter of 3 mm.

Embodiment 3

[0079] Put 5g of quartz, 4g of polyvinylpyrrolidone, 8g of polyethylene terephthalate, and 2g of polymethyl methacrylate in a container jar, and stir at 60°C for 40 minutes to prepare a slurry; among them, the quartz particles The particle size is 100nm;

[0080] Cool the slurry to normal temperature, add 8g of carbon nanotubes and continue stirring for 20 minutes to prepare the precursor slurry;

[0081] Add 30g of epoxy resin and 20g of curing agent to the precursor slurry in sequence, and continue stirring for 30 minutes to obtain polymer slurry;

[0082] The polymer slurry was injected into a mold to produce a polymer with a thickness of 30 mm and a diameter of 60 mm. This polymer is suitable for irradiation with red light with a wavelength of 701-760nm.

[0083] When preparing the terahertz converter, the exit hole 301 at the bottom of the cup-shaped housing 310 has a diameter of 5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com