Preparation method of cobalt phosphide nanoparticles

A nanoparticle and cobalt phosphide technology, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of reducing mass transfer efficiency, weak conductivity, and affecting catalyst activity, and achieve accelerated reaction, reduced covering, excellent activity and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

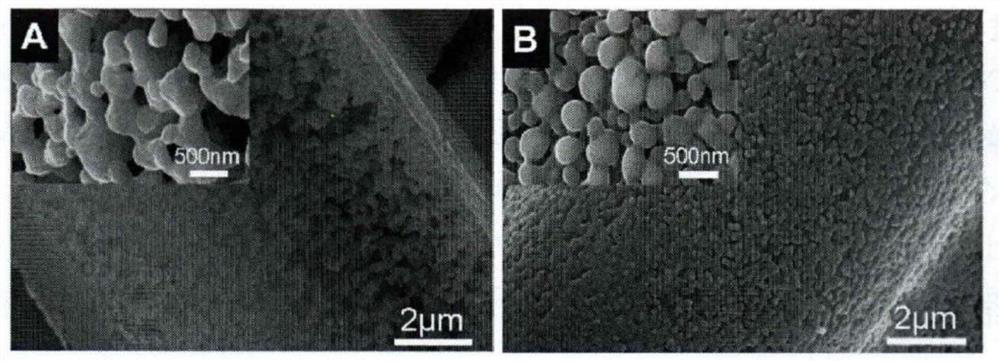

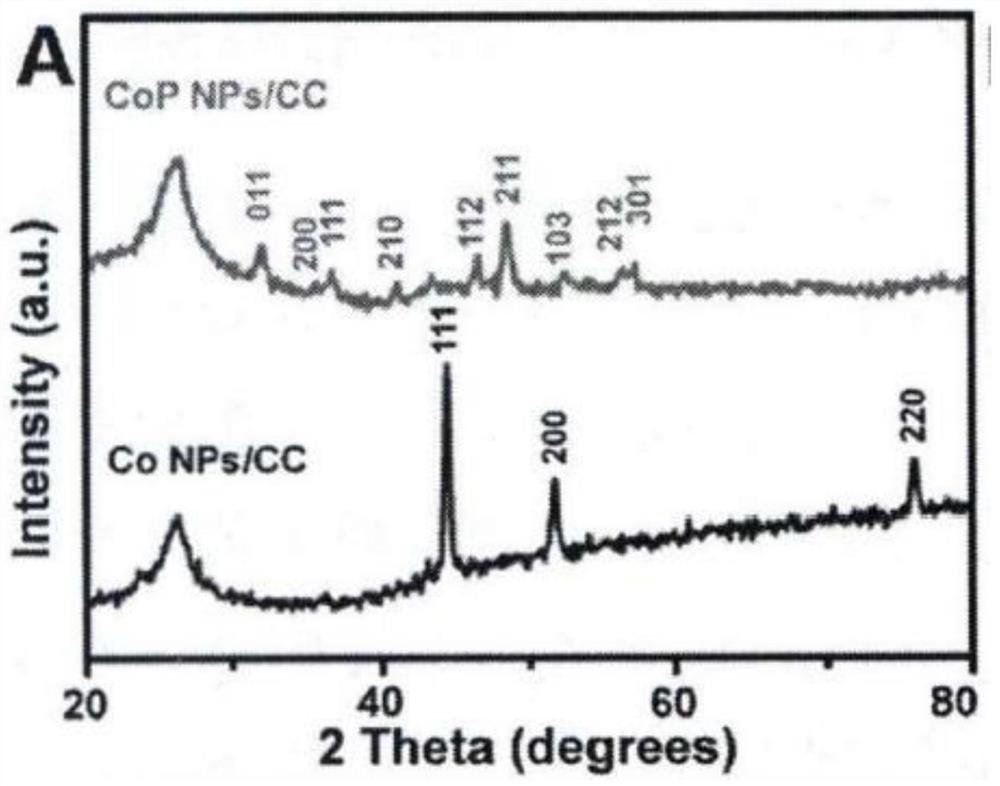

[0024] S1. Add 6.3g of cobalt chloride hexahydrate and 1g of polyvinylpyrrolidone into 8ml of N,N-dimethylformamide, heat and stir at 80°C until dissolved to obtain a viscous solution;

[0025] S2, then soak the 1cm×1cm carbon cloth into the viscous solution in step S1, and then dry the carbon cloth with the cobalt precursor attached at 80°C;

[0026] S3, then put it in a tube furnace with a protective gas atmosphere to raise the temperature to 600°C at a rate of 10°C / min and continue to maintain it for 2h to obtain elemental cobalt nanoparticles (CoNPs / CC) uniformly grown on the surface of the carbon cloth;

[0027] S4. Subsequently, CoNPs / CC and sodium hypophosphite were placed in a tube furnace with a protective gas atmosphere to raise the temperature to 300°C at a rate of 2°C / min and continue to maintain for 2h;

[0028] S5. Finally, cobalt phosphide nanoparticles (CoP NPS / CC) were obtained after the tube furnace cooled naturally.

Embodiment 2

[0030] S1. Add 4g of cobalt chloride hexahydrate and 0.5g of polyvinylpyrrolidone into 5ml of N,N-dimethylformamide, heat and stir at 80°C until dissolved to obtain a viscous solution;

[0031] S2, then soak the 1cm×1cm carbon cloth into the viscous solution in step S1, and then dry the carbon cloth with the cobalt precursor attached at 80°C;

[0032] S3, then put it in a tube furnace with a protective gas atmosphere to raise the temperature to 600°C at a rate of 10°C / min and continue to maintain it for 2h to obtain elemental cobalt nanoparticles (CoNPs / CC) uniformly grown on the surface of the carbon cloth;

[0033] S4. Subsequently, CoNPs / CC and sodium hypophosphite were placed in a tube furnace with a protective gas atmosphere to raise the temperature to 300°C at a rate of 2°C / min and continue to maintain for 2h;

[0034] S5. Finally, cobalt phosphide nanoparticles (CoP NPS / CC) were obtained after the tube furnace cooled naturally.

Embodiment 3

[0036] S1. Add 2.4g of cobalt chloride hexahydrate and 0.2g of polyvinylpyrrolidone into 4ml of N,N-dimethylformamide, heat and stir at 80°C until dissolved to obtain a viscous solution;

[0037] S2, then soak the 1cm×1cm carbon cloth into the viscous solution in step S1, and then dry the carbon cloth with the cobalt precursor attached at 80°C;

[0038] S3, then put it in a tube furnace with a protective gas atmosphere to raise the temperature to 600°C at a rate of 10°C / min and continue to maintain it for 2h to obtain elemental cobalt nanoparticles (CoNPs / CC) uniformly grown on the surface of the carbon cloth;

[0039] S4. Subsequently, CoNPs / CC and sodium hypophosphite were placed in a tube furnace with a protective gas atmosphere to raise the temperature to 300°C at a rate of 2°C / min and continue to maintain for 2h;

[0040] S5. Finally, cobalt phosphide nanoparticles (CoP NPS / CC) were obtained after the tube furnace cooled naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com