Durable antiskid plastic runway and preparation method thereof

A plastic track, anti-skid technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of scratching the skin, large friction resistance of the anti-skid surface layer, short service life, etc. Avoid the effect of rainwater infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

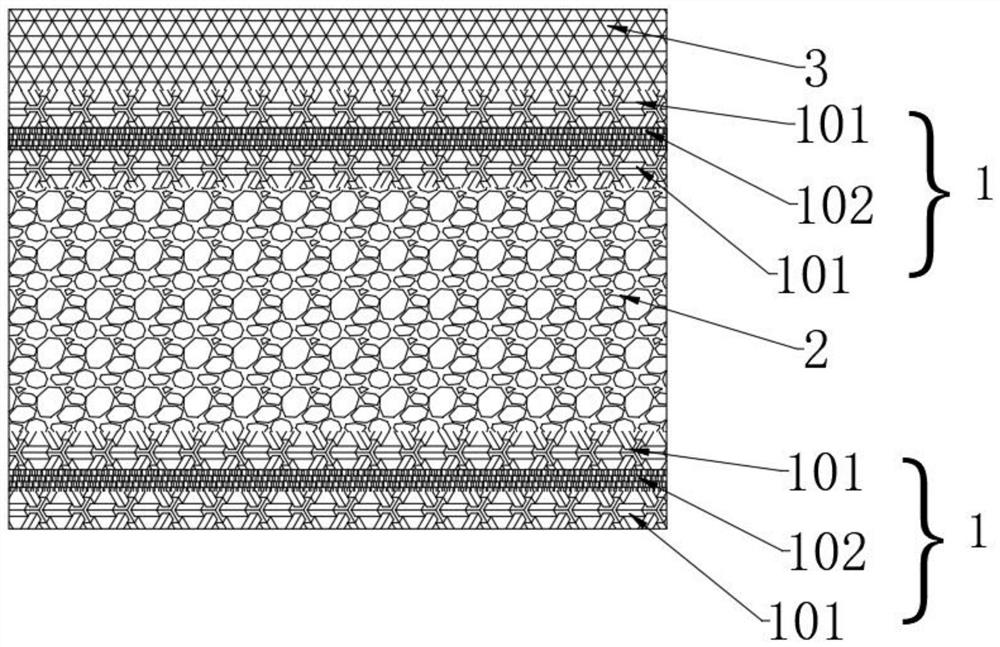

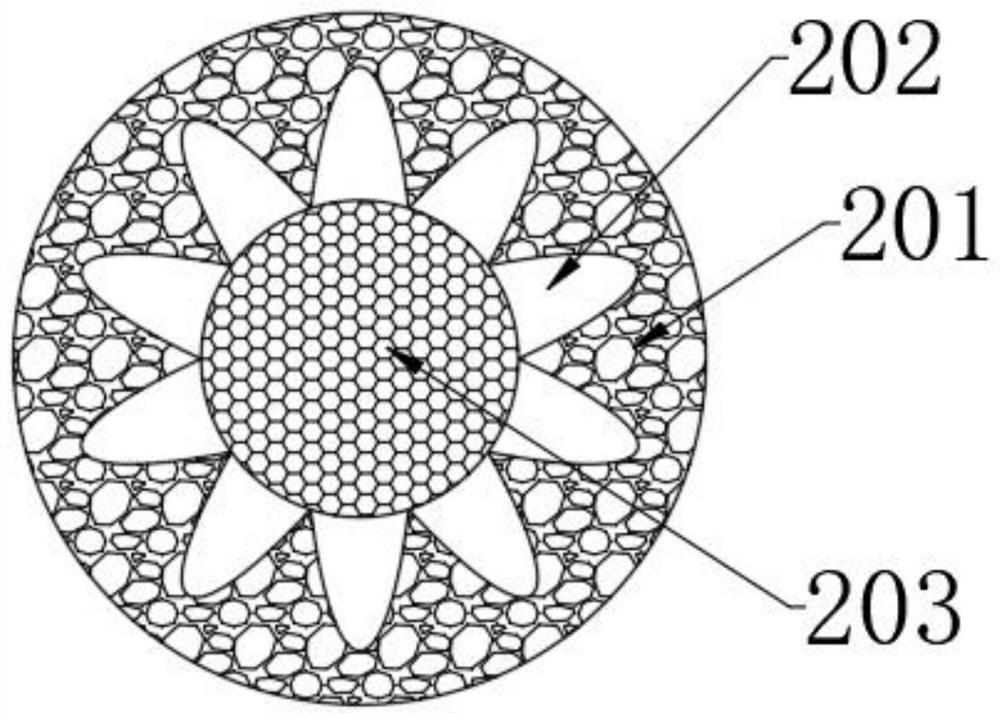

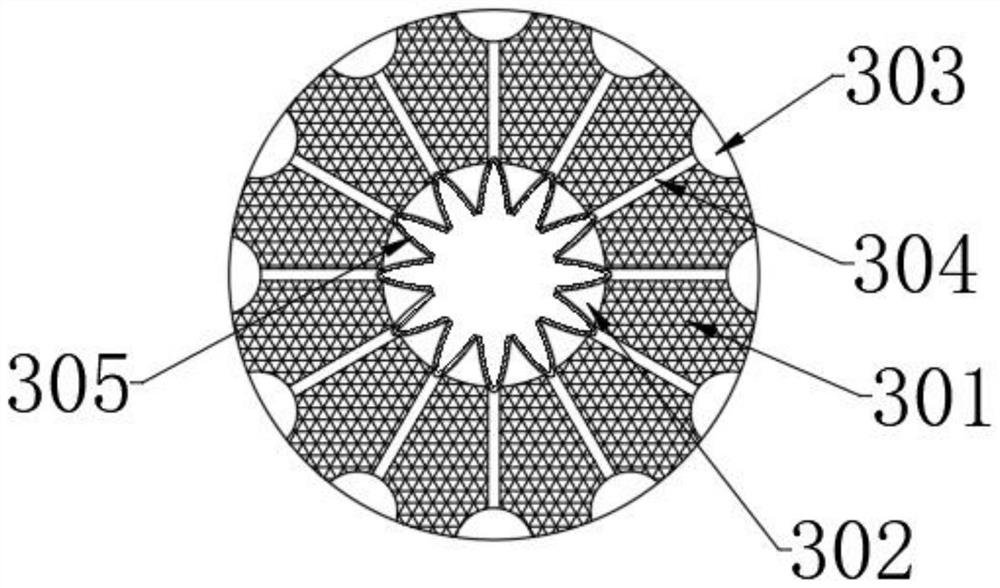

[0046] see Figure 1-8 , a durable non-slip plastic runway, see Figure 1-3 , including two layers of wrapping layer 1, plastic field elastic layer 2 and plastic field non-slip surface layer 3, the plastic field elastic layer 2 is located between the wrapping layers 1 on both sides, and the thickness of the plastic field elastic layer 2 is 8 mm, the plastic field is non-slip The surface layer 3 is located above the wrapping layer 1, and the thickness of the anti-skid surface layer 3 of the plastic field is 3mm. The wrapping layer 1 includes two layers of polymer elastic fibers 101 and polymer airtight film 102, and the polymer elastic fibers 101 and high polymer airtight The thickness of the molecular airtight film 102 is 0.4mm and 0.2mm respectively, the polymer airtight film 102 is located between two layers of polymer elastic fibers 101, and the plastic field elastic layer 2 is made of foamed polyurethane material and micro-foamed thermoplastic polyurethane The particle 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com