Preparation method of fluorescent thin block and trace explosive TATP optical fiber fluorescent probe

An optical fiber probe, fluorescence technology, applied in fluorescence/phosphorescence, measurement device, material analysis by optical means, etc., can solve the problem of inability to detect TATP in real time, fast and non-contact, and achieve fast film formation speed and high sensitivity , the effect of reducing the detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the method for preparing the fluorescent sensitive thin film in this embodiment comprises the following steps:

[0037] 1) Clean and dry the glass substrate, which includes:

[0038] 1a) Cleaning the surface of the glass substrate with deionized water and absolute ethanol in sequence, and then drying the cleaned glass substrate in a vacuum drying oven;

[0039] 1b) Put the dried glass substrate into acetone or analytical grade, and place it in an ultrasonic cleaner for 30 minutes of ultrasonic vibration; after the vibration, take out the glass substrate, clean it with deionized water, and dry it in a vacuum oven.

[0040] Of course, in different embodiments, other methods can also be used for cleaning and drying the glass substrate.

[0041] 2) Place the dried glass substrate in a vacuum evaporation equipment, and evacuate to a pressure of 3×10 -4 Below Pa, the evaporation current is about Control the evaporation rate as Take it out when the thicknes...

Embodiment 2

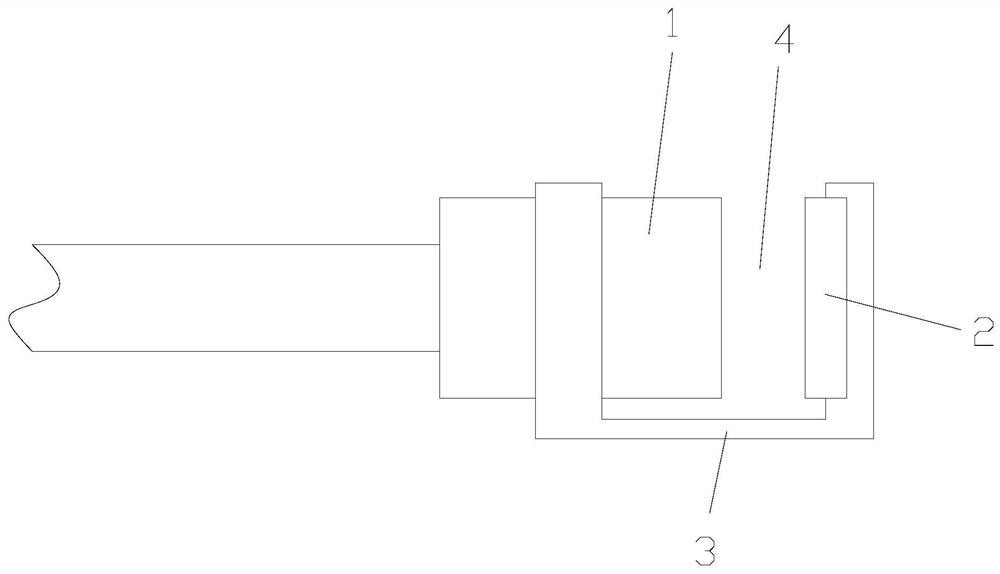

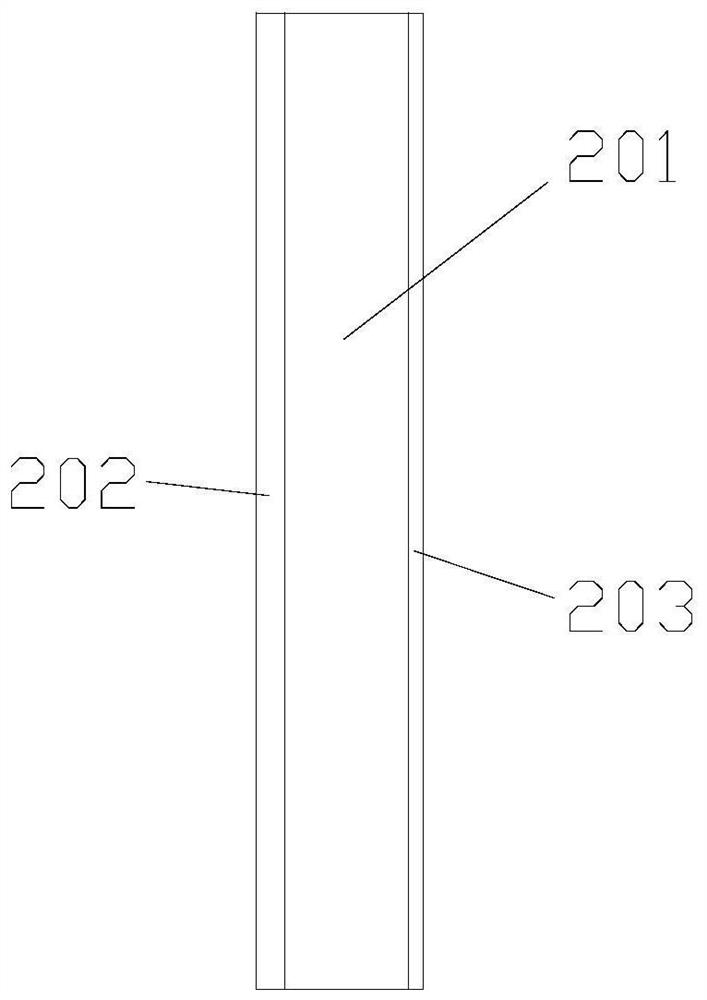

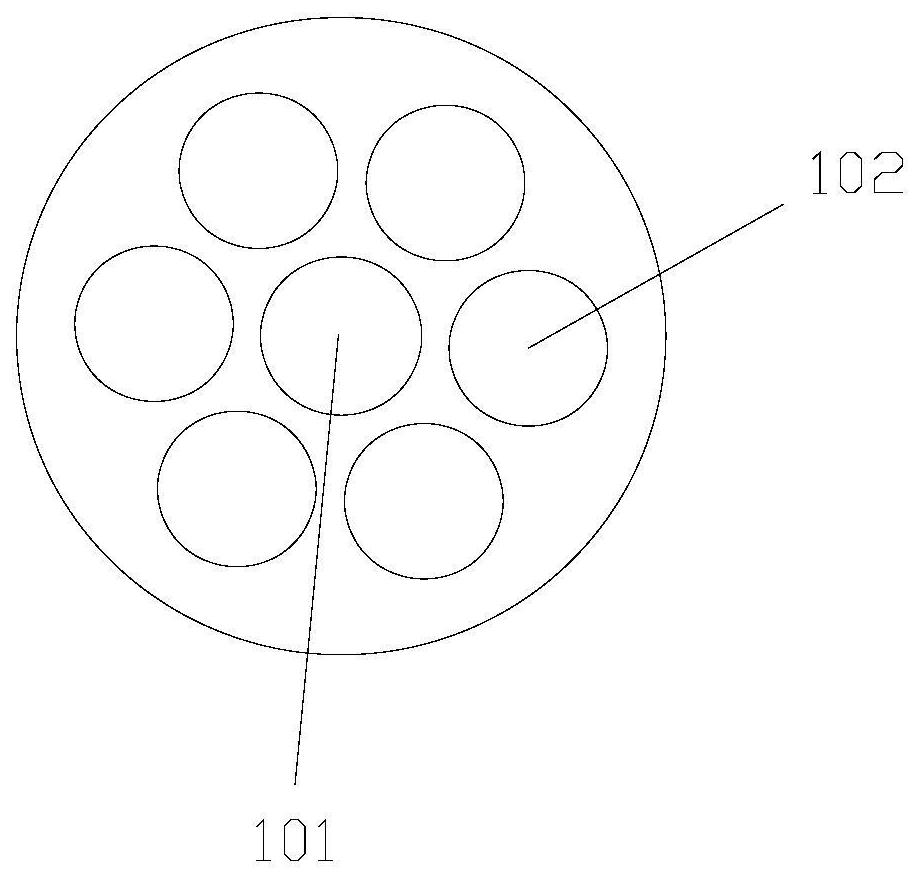

[0047] Embodiment 2: In this embodiment, the trace explosive TATP optical fiber fluorescence probe includes a reflective optical fiber probe 1, and also includes a fluorescent thin block 2 fixed in front of the reflective optical fiber probe. The reflective optical fiber probe described in this embodiment is provided with Bracket 3, the fluorescent thin block 2 is fixed in front of the reflective fiber optic probe through the bracket 3. The fluorescent thin block includes a glass substrate 201 and a DNNDI-containing fluorescent sensitive film 202 covered on the front of the glass substrate. The fluorescent sensitive film faces the reflective optical fiber probe, and there is a gap between the front end of the reflective optical fiber probe and the fluorescent thin block to make the explosion The gap 4 where the substance vapor is in contact with the fluorescent sensitive film. In this embodiment, the width of the gap 4 is 5 mm, of course, the width of the gap 4 can also be adj...

example 1

[0061] Example 1: The thickness of the DNNDI-containing fluorescence sensitive film coated on the glass substrate of the trace explosive TATP fiber optic fluorescence probe is 60 nm. Different concentrations of TATP vapor were used as research objects, and different concentrations of TATP vapor were used in different experiments to interact with fluorescent sensitive films coated on glass substrates.

[0062] The TATP vapor concentrations used in the experiment were respectively selected from 0ppb (nitrogen), 40ppb, 80ppb, 120ppb, 160ppb and 200ppb. The spectrometer integration time was set to 3 ms. The measured changes in fluorescence intensity ΔF were 0, 131 (a.u), 262 (a.u), 355 (a.u), 531 (a.u), and 703 (a.u), respectively. The linear fitting equation was calculated: ΔF=3.4343C-13.095, correlation coefficient R2=0.9909, so k=3.4343, b=-13.095 in the obtained fitting equation.

[0063] When the TATP vapor to be measured is in contact with the fluorescent sensitive film on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com