A kind of electrodeless cylindrical battery and preparation method thereof

A cylindrical battery, electrodeless ear technology, applied in the direction of cylindrical shell battery/battery, secondary battery manufacturing, battery, etc., can solve the problems of insufficient safety performance, increased battery quality, large current collector quality, etc., to reduce battery quality. , The effect of improving the resistivity difference and improving the safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a preparation method of a cylindrical battery without tabs, which does not need to be welded by tabs, and adopts light-weight positive electrode composite current collector and negative electrode composite current collector, which significantly improves the energy density of the battery. The preparation method includes:

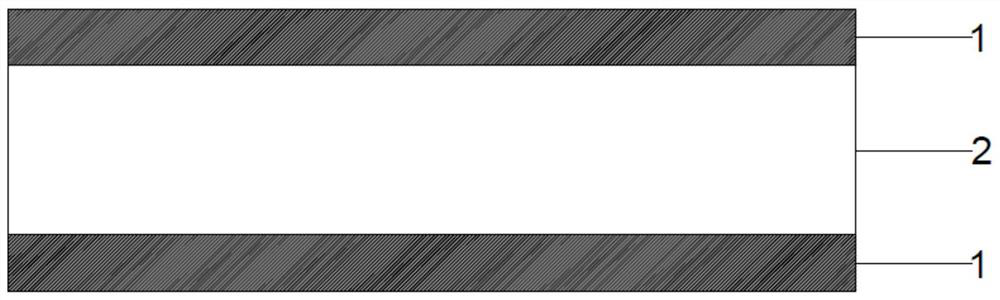

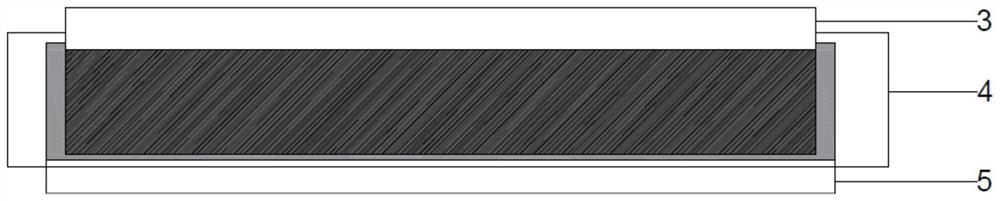

[0028] S1: The positive electrode composite current collector and the negative electrode composite current collector are respectively coated with a positive electrode active material and a negative electrode active material, and a part of an uncoated area is provided on one side of the coated surface, wherein the positive electrode composite current collector and the negative electrode composite current collector include three layers (such as figure 1 shown), wherein the middle layer is a polymer material layer 2, and both sides of the polymer material layer are a conductive metal material layer 1;

[0029] The material of the p...

Embodiment 1

[0038] In this embodiment, the polymer material layer of the positive electrode composite current collector is made of polyvinylidene fluoride (PVDF), and the thickness of the polymer material layer is 3 μm; the conductive metal material layers on both sides are made of aluminum with a thickness of 1000 nm. The material of the polymer material layer of the negative electrode composite current collector is polypropylene (PP); the material of the conductive metal material layers on both sides is copper, and the thickness is 500 nm. The battery is made by gap coating, and the width of the uncoated area is 5 mm. After winding, the uncoated area is flattened, and then the side of the uncoated area and the metal shell of the cylindrical battery are welded together by laser welding. The specific production steps are as follows:

[0039] Step 1: The polyvinylidene fluoride material of the coil structure is used as the polymer material layer, and it is wound on the drum. The drum is se...

Embodiment 2

[0047] In this embodiment, the material of the polymer material layer of the positive electrode composite current collector is polyethylene terephthalate (PET), and the thickness of the polymer material layer is 6 μm; the material of the conductive metal material layers on both sides is aluminum Silver alloy with a thickness of 800nm. The material of the polymer material layer of the negative electrode composite current collector is polyimide (PI); the material of the conductive metal material layers on both sides is copper-nickel, and the thickness is 400m. The battery was fabricated by gap coating, and the width of the uncoated area was 6 mm. After winding, the uncoated area was flattened, and then the side of the uncoated area and the metal casing of the cylindrical battery were welded together by laser welding. The specific production steps are as follows:

[0048] Step 1: The polyethylene terephthalate material of the coil structure is used as the polymer material layer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com