Preparation system for producing building material products by gradient utilization of pyrolytic steel slag

A technology for preparing system and steel slag, applied in magnetic separation, solid separation, sieve and other directions, can solve the problems of high production cost, high production energy consumption, poor stability, etc., to save resources, reduce investment costs, and achieve a variety of product types the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

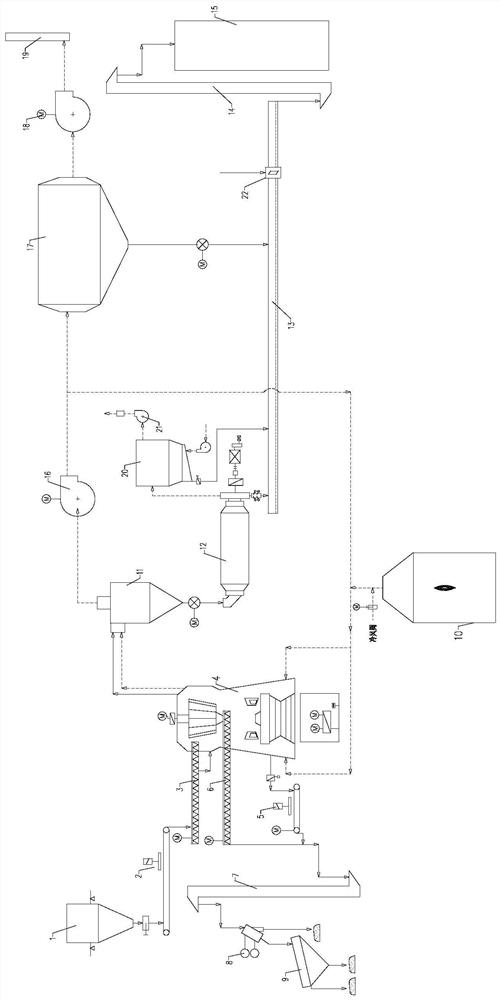

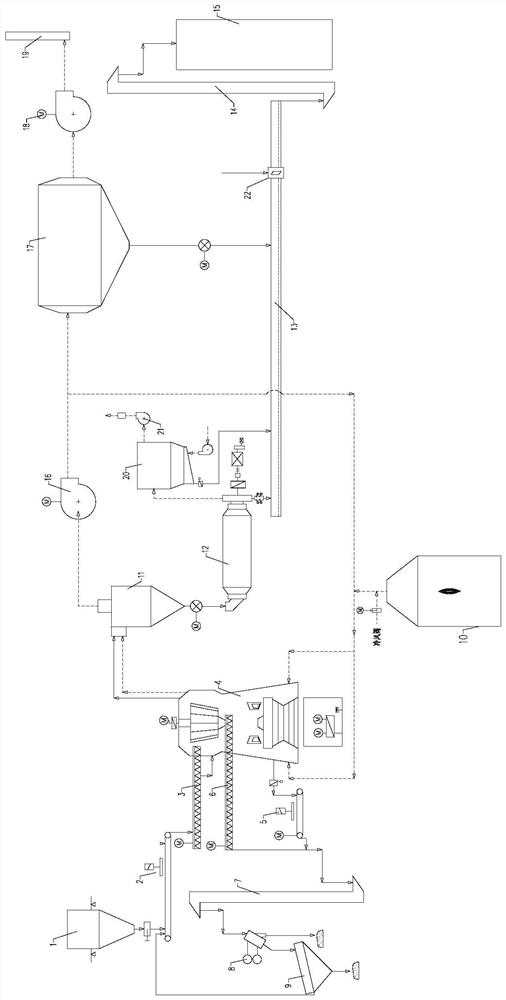

[0042] A preparation system for producing building material products by gradient utilization of hot stuffy steel slag, the preparation system for producing building material products by gradient utilization of hot stuffy steel slag includes a raw material warehouse, a suspended iron remover A, a conveying reamer, a steel slag vertical mill, and a suspended iron remover B , Built-in conveying reamer, elevator A, magnetic separator, vibrating screen, hot blast furnace, cyclone, ball mill, conveying chute, elevator B, micro powder bin, circulation fan, dust collector A, dust collection fan A, Chimney, dust collector B and dust collection fan B. The raw material bin is connected to the steel slag vertical mill through a conveying reamer. A suspended iron remover A is installed between the raw material bin and the steel slag vertical mill. There are grinding discs, grinding rollers and powder selection components, the fine powder passing through the powder selection components is co...

Embodiment 2

[0055] Furthermore, it can also be considered in the embodiment that the coarse aggregate is transported to the steel slag vertical mill for grinding through the conveying device until all the materials become fine powder and fine aggregate.

[0056] The hot stuffy steel slag gradient utilization production technology is based on the grindability difference of different mineral phases in the hot stuffy steel slag, the easy-to-grind materials are ground and the difficult-to-grind materials are kept in granular form, and the steel slag gradient utilization is used to produce fine powder, fine Aggregate and coarse aggregate, or produce fine powder and fine aggregate.

[0057] In summary, the present invention provides a method for classifying and utilizing the hot stuffy steel slag according to the raw material characteristics of the hot stuffy steel slag, preparing the easy-to-grind components into fine powder, and the difficult-to-grind components into coarse aggregate and fine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com