Thermal insulation mortar and preparation method thereof

A thermal insulation and mortar technology, applied in the field of construction, can solve the problems of easy water absorption of lightweight porous wall materials, easy combustion of organic thermal insulation materials, low thermal insulation performance, etc. The effect of stabilizing and improving the fire resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment.

[0024] In the present invention, unless otherwise specified, all equipment and raw materials are commercially available common materials.

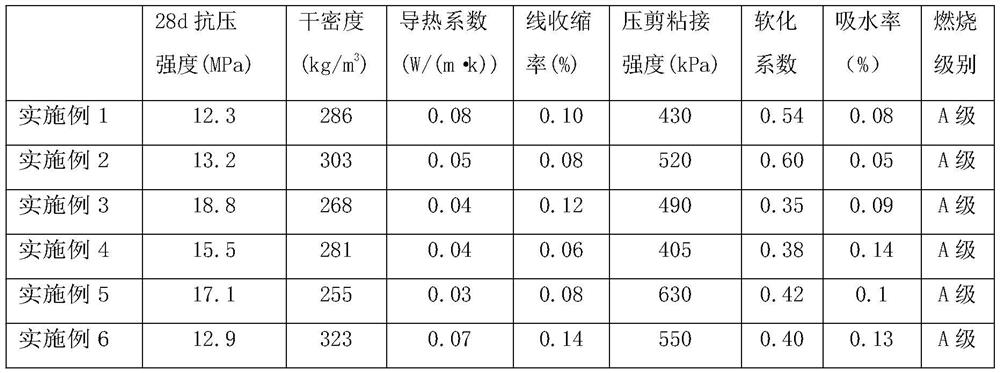

[0025] The present invention has 6 embodiments in total, and the raw material components of Embodiment 1 to Embodiment 6 are shown in Table 1.

[0026] Table 1: Embodiment 1 to embodiment 6 raw material composition table

[0027] Raw materials (parts by weight) Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 cement 300 450 380 505 410 600 fine aggregate 100 150 210 185 200 250 fly ash 50 48 38 40 35 30 talcum powder 20 33 27 35 40 24 Silicone water repellent 0.5 0.9 1.7 1.4 1.5 2 Zirconia Hollow Ball 20 70 92 65 80 100 water retention component 0.2 0.3 0.5 0.45 0.52 0.6 Toner 5 7 9.5 6.5 8 10 transition metal oxide powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com