Ardealite-based lightweight plastering gypsum and preparation method thereof

A technology of plastering gypsum and phosphogypsum, which is applied in the field of building materials, can solve problems such as adverse environmental effects, affecting product appearance and performance, and achieve the effects of low shrinkage, low hollowing, good water retention and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

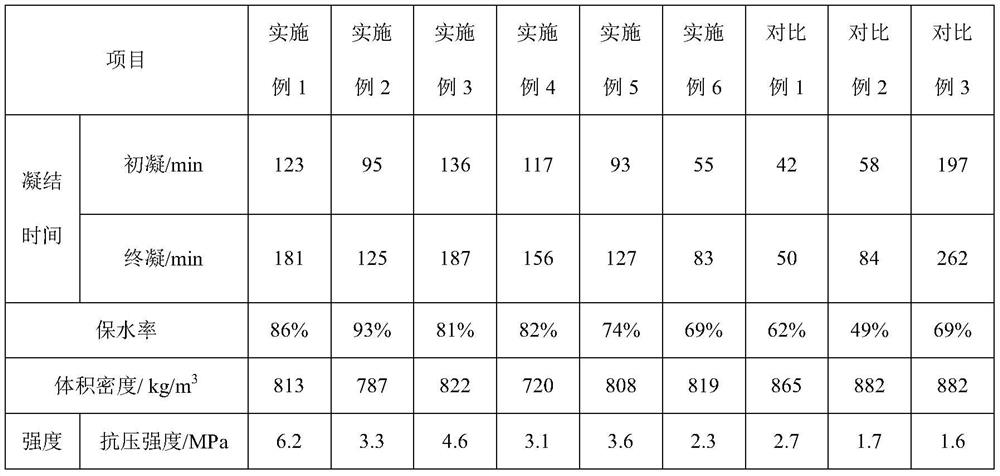

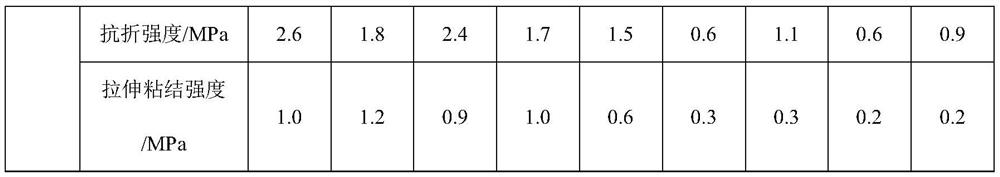

Examples

preparation example Construction

[0033] The phosphogypsum-based light-weight plastering gypsum provided in the embodiments, in terms of mass percentage, raw materials include: calcined phosphogypsum and alum 50-60%, cement 5-10%, heavy calcium 20-35%, vitrified microbeads 8 -10%, 0.2-0.25% cellulose, 0.2-0.5% coupling agent, 0.04-0.05% viscosifier, 0.01-0.05% retarder. The calcined phosphogypsum and alum are formed by mixing and calcining alunite raw ore and phosphogypsum, and the preparation method includes the following steps:

[0034] S1. First mix the cellulose, coupling agent and water in a certain proportion, stir and heat to 70-90°C under the condition of 200-400rpm, keep it warm for 15-45min, and then cool to room temperature to obtain solution a;

[0035] S2. Add the solution a to the low-alkali solution whose pH of the retarder is 8-9, and stir at a speed of 200-400 rpm for 10-30 minutes at room temperature to prepare the solution b;

[0036] S3. Add solution b and tackifier to an appropriate amoun...

Embodiment 1

[0038] A phosphogypsum-based lightweight plastering gypsum, including the following raw materials: 550 kg of calcined phosphogypsum and alum, 62 kg of cement, 300 kg of heavy calcium, 80 kg of vitrified microbeads, 2 kg of cellulose, 5 kg of coupling agent, and 0.5 kg of viscosifying agent kg, retarder 0.5kg. Among them, the mass ratio of alunite:phosphogypsum is 1:100, and the calcination condition is 600°C for 1 hour. The preparation process is as follows:

[0039] (1) First mix the cellulose, coupling agent and water at a mass ratio of 2:5:93, stir and heat to 70°C under the condition of 200rpm, keep it warm for 30min, and then cool to room temperature to obtain solution a;

[0040] (2) Add solution a to a low-alkali solution of 5 wt% bone collagen retarder, and stir at a speed of 200 rpm for 15 minutes at room temperature to obtain solution b; the pH of the low-alkali solution is 8;

[0041] (3) Add solution b and tackifier to an appropriate amount of water, then mix the ...

Embodiment 2

[0043] This example is basically the same as Example 1, except that the composition of lightweight plastering gypsum is: 550kg of calcined phosphogypsum and alum, 50kg of cement, 300kg of heavy calcium, 92kg of vitrified microbeads, 2.5kg of cellulose, and a coupling agent 5kg, viscosifier 0.4kg, retarder 0.1kg; The cellulose described in step S1, coupling agent and water are mixed by mass ratio 2.5:5:92.5; The low alkali solution in S2 contains 1wt% collagen protein retardation Agent; Other preparation process of plastering gypsum is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com