Synthetic method of mixed-valence rare earth iron-based oxide block material

A technology of iron-based oxides and bulk materials, applied in the field of inorganic non-metallic functional ceramic powder materials, can solve the problems of poor repeatability of material performance, complicated and dangerous preparation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

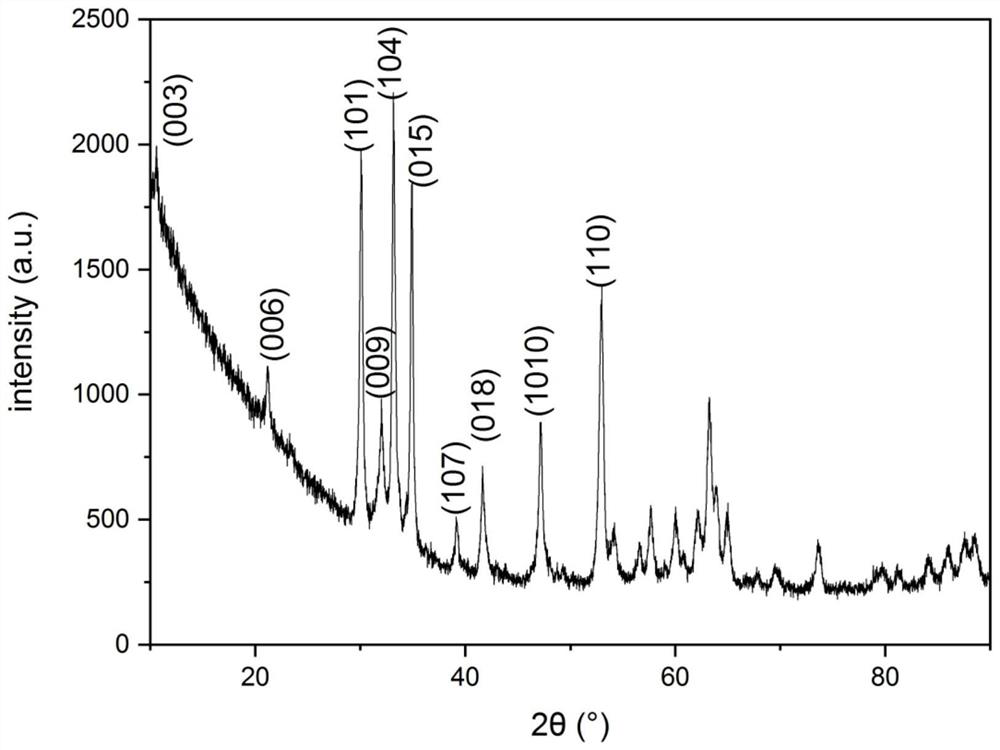

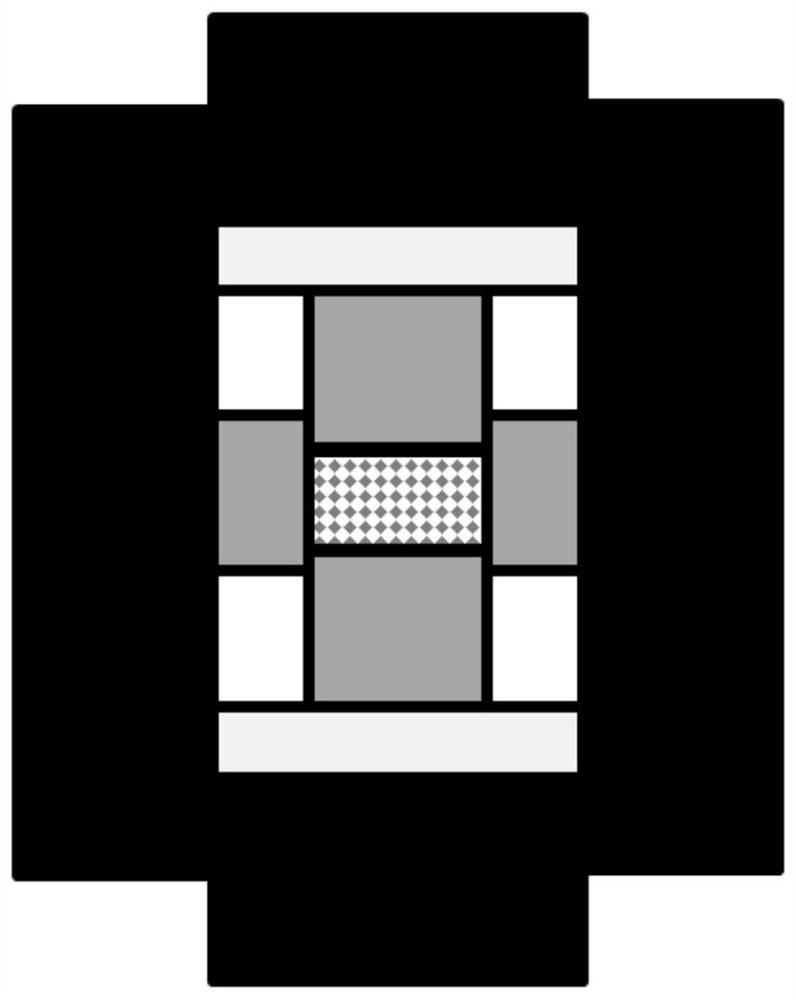

[0055] Mix ytterbium oxide and iron oxide powder according to the stoichiometric ratio, grind and mix by hand or high-energy ball mill, then put it into graphite mold for cold pressing, add carbon paper, and heat in a medium and low vacuum environment of 0.1-200Pa with a pulse current of 100-2000A Apply a pressure of 20-60MPa to 1000-1100°C and anneal in situ at 1000-1100°C for 2-10min to obtain YbFe 2 o 4 blocks. Its XRD spectrum is as figure 1 As shown, it is proved that the successful synthesis of YbFe 2 o 4 bulk material.

Embodiment 2

[0057] Mix lutetium oxide and iron oxide powder according to the stoichiometric ratio and mix them manually or by high-energy ball milling, put them into a graphite mold for cold pressing, add carbon paper, and heat in a medium-to-low vacuum environment of 0.1-200Pa with a pulse current of 100-2000A Apply a pressure of 20-60MPa to 1000-1100°C and anneal in situ at 1000-1100°C for 2-10min to obtain LuFe 2 o 4 blocks. The successful synthesis of YbFe was proved by XRD spectrum 2 o 4 bulk material.

Embodiment 3

[0059] Mix thulium oxide and iron oxide powder according to the stoichiometric ratio, grind and mix by hand or high-energy ball mill, put them into graphite mold for cold pressing, add carbon paper, and heat in a medium and low vacuum environment of 0.1-200Pa by pulse current 100-2000A Apply a pressure of 20-80MPa to 1050-1150°C and anneal in situ at 1050-1150°C for 2-10min to obtain TmFe 2 o 4 blocks. The successful synthesis of YbFe was proved by XRD spectrum 2 o 4 bulk material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com