Bi3+/Eu3+ co-activated lutetium acid salt fluorescent powder and preparation method thereof

A phosphor and lutetate technology, which is applied in the field of lutetate-based phosphor and its preparation, achieves the effect of meeting LED packaging requirements, good thermal stability, and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

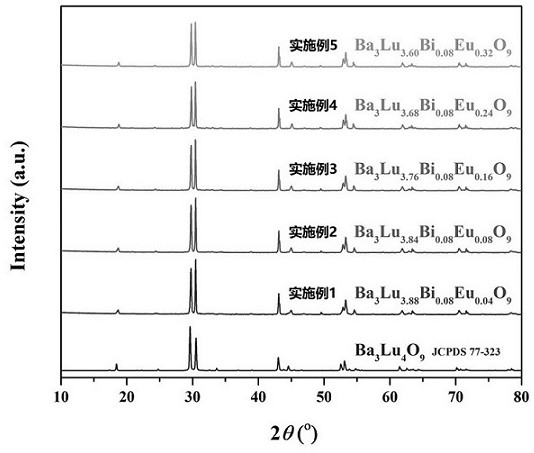

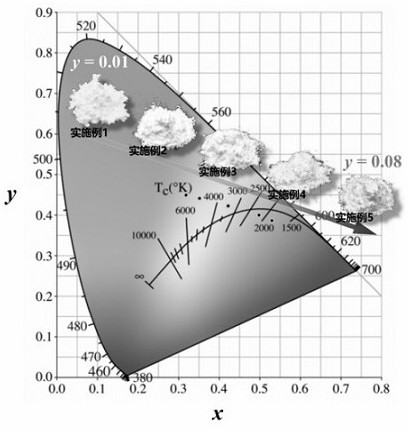

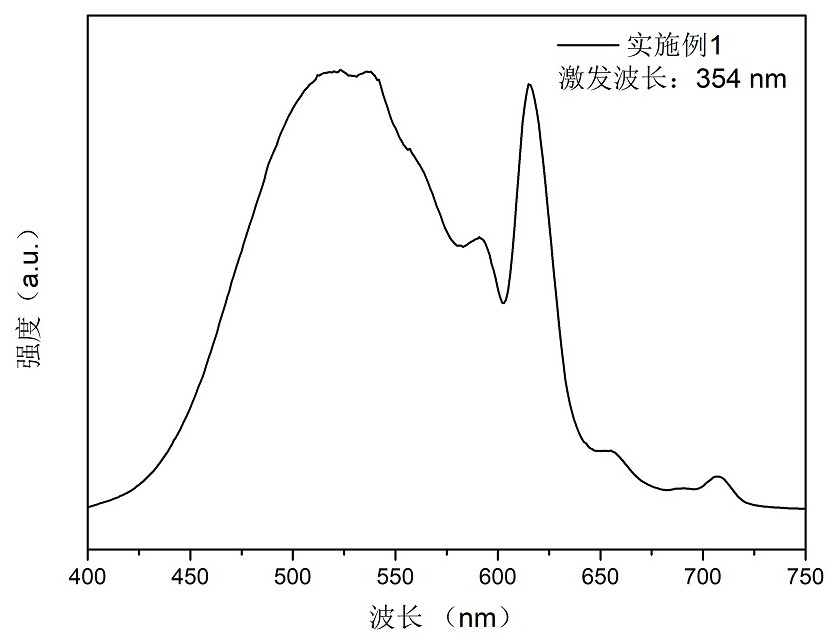

[0034] Preparation of Ba 3 Lu 3.88 Bi 0.08 Eu 0.04 o 9 Phosphor powder, the specific steps are as follows:

[0035] with BaCO 3 、Lu 2 o 3 、 Bi 2 o 3 、Eu 2 o 3 As the raw material, weigh the raw material according to the molar mass ratio of Ba:Lu:Bi:Eu is 3:3.88:0.08:0.04, put the above raw material in an agate mortar and grind it for 60 minutes, add volatile anhydrous Ethanol or acetone solvent to improve the grinding quality and promote particle refinement, which is conducive to the full reaction between raw materials during calcination. The fully ground and mixed raw materials were transferred to a corundum crucible, sintered at 1550°C for 5 hours under normal pressure and air atmosphere, and cooled naturally to room temperature to obtain a sintered product. The sintered product was crushed in an agate mortar, ground evenly, sieved, washed and dried to obtain Ba 3 Lu 3.88 Bi 0.08 Eu 0.04 o 9 Phosphor.

[0036] For the XRD spectrum of the fluorescent powder ...

Embodiment 2

[0040] Preparation of Ba 3 Lu 3.84 Bi 0.08 Eu 0.08 o 9 Phosphor powder, the preparation method and luminous performance of the phosphor powder are basically the same as in Example 1, and the specific steps are briefly described as follows:

[0041] with BaCO 3 、Lu 2 o 3 、 Bi 2 o 3 、Eu 2 o 3 As the raw material, weigh the raw material according to the molar mass ratio of Ba:Lu:Bi:Eu is 3:3.84:0.08:0.08, put the above raw material in an agate mortar and grind it for 60 minutes, add volatile anhydrous Ethanol or acetone solvent to improve the grinding quality and promote particle refinement, transfer the fully ground and mixed raw materials to a corundum crucible, sinter at 1550 ℃ for 5 hours under normal pressure and air atmosphere, and naturally cool to room temperature to obtain a sintered product . The sintered product was crushed in an agate mortar, ground evenly, sieved, washed and dried to obtain Ba 3 Lu 3.84 Bi 0.08 Eu 0.08 o 9 Phosphor. For the XRD spec...

Embodiment 3

[0045] Preparation of Ba 3 Lu 3.76 Bi 0.08 Eu 0.16 o 9 Phosphor powder, the preparation method and luminous performance of the phosphor powder are basically the same as in Example 1, and the specific steps are briefly described as follows:

[0046] with BaCO 3 、Lu 2 o 3 、 Bi 2 o 3 、Eu 2 o 3 As the raw material, weigh the raw material according to the molar mass ratio of Ba:Lu:Bi:Eu is 3:3.76:0.08:0.16, put the above raw material in an agate mortar and grind for 60 minutes, add volatile anhydrous Ethanol or acetone solvent to improve the grinding quality and promote particle refinement, transfer the fully ground and mixed raw materials to a corundum crucible, sinter at 1550 ℃ for 5 hours under normal pressure and air atmosphere, and naturally cool to room temperature to obtain a sintered product . The sintered product was crushed in an agate mortar, ground evenly, sieved, washed and dried to obtain Ba 3 Lu 3.76 Bi 0.08 Eu 0.16 o 9 Phosphor. For the XRD spectru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com