Nitrile hydratase lysine mutant HBA-K2H1, coding gene and application

A nitrile hydratase lysine, encoding gene technology, applied in the application, genetic engineering, plant genetic improvement and other directions, can solve problems such as artificial regulation of the self-modification efficiency of nitrile hydratase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Site-directed mutagenesis of nitrile hydratase HBA

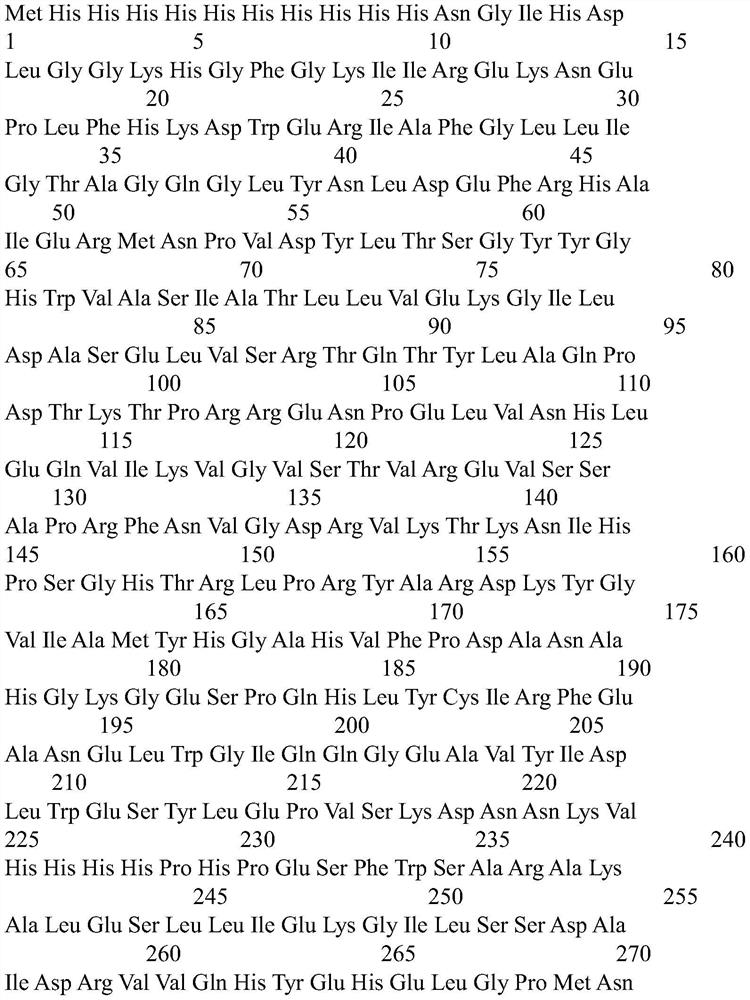

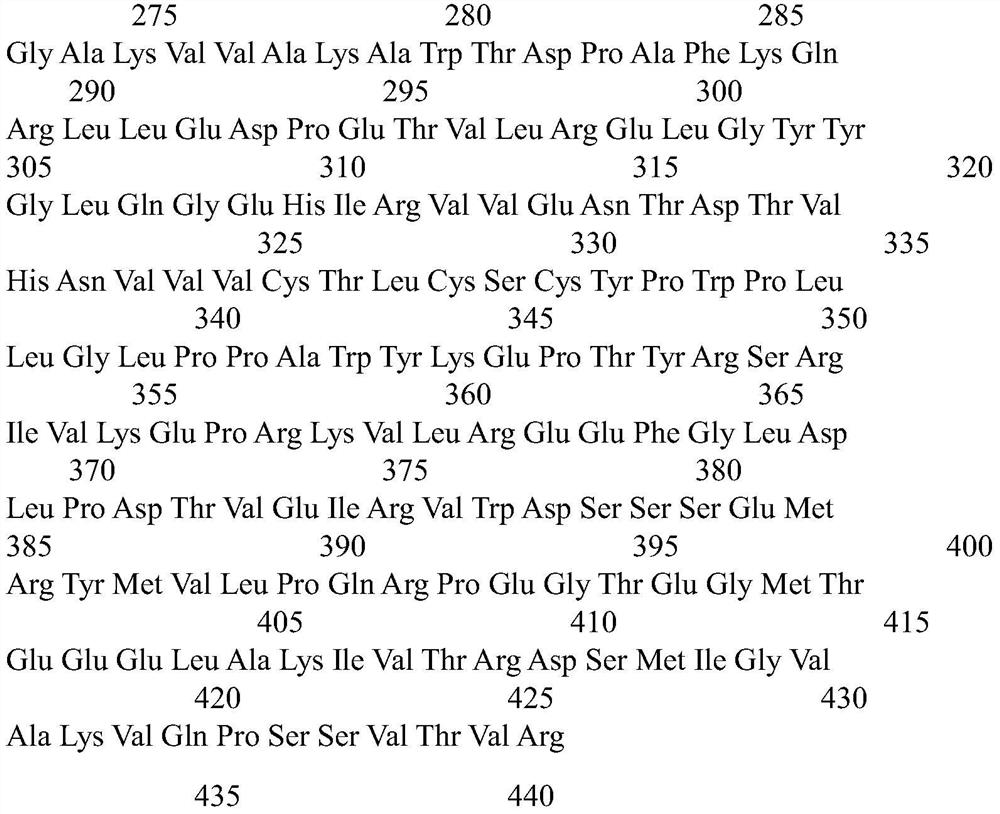

[0038] 1) Extract the recombinant plasmid pET-28-HBA containing the nitrile hydratase HBA gene from recombinant Escherichia coli according to the instructions of the plasmid mini-extraction kit from Axygen Company. The amino acid sequence of wild-type nitrile hydratase HBA is shown in SEQ ID NO.3.

[0039] 2) Design site-directed mutagenesis primers 5'-CAAACATGGTTTCGGCAAGATCATTCGTGAGAAAAACGAGCCGCTGTTCC-3'(SEQ ID NO.5) and 5'-GATCTTGCCGAAACCATGTTTGCCACCCAGG TCGTGG-3'(SEQ ID NO.5) according to the nucleotide sequence (SEQ ID NO.4) of wild-type nitrile hydratase HBA ID NO.6).

[0040] 3) According to the instructions of the Fast Mutagenesis System Kit of Beijing Quanshijin Biotechnology Co., Ltd., the recombinant plasmid pET-28-HBA obtained in step 1 was used as a template, and the primers synthesized in step 2 were used for single-site site-directed mutagenesis PCR.

[0041] 4) Transform the site-directed m...

Embodiment 2

[0042] Embodiment 2: Enzyme preparation of nitrile hydratase mutant HBA-K2H1 and wild-type HBA

[0043] 1) Recombinant strains containing mutant HBA-K2H1 and wild-type HBA were respectively inoculated in LB (50 μg / mL Kan) culture medium at an inoculation amount of 0.1%, and cultured with shaking at 180 rpm for 16 hours at 37°C.

[0044] 2) Inoculate the 1% inoculum of the activated bacterial solution overnight into fresh LB (containing 50 μg / mL Kan) culture solution, culture at 37°C with shaking at 180 rpm for 3 h (OD 600nm reach 0.6-1.0).

[0045] 3) Add IPTG (isopropylthiogalactopyranoside) at a final concentration of 0.5 mM for induction, and culture at 20° C. with shaking at 150 rpm for about 20 h.

[0046] 4) Centrifuge at 8000rpm for 5min, collect the cells and suspend the cells with PBS buffer.

[0047] 5) Ultrasonic disrupt the bacteria in a low-temperature ice-water bath. Ultrasonic crushing conditions are: power 300W, 5s on, 10s off, temperature 4°C, effective cru...

Embodiment 3

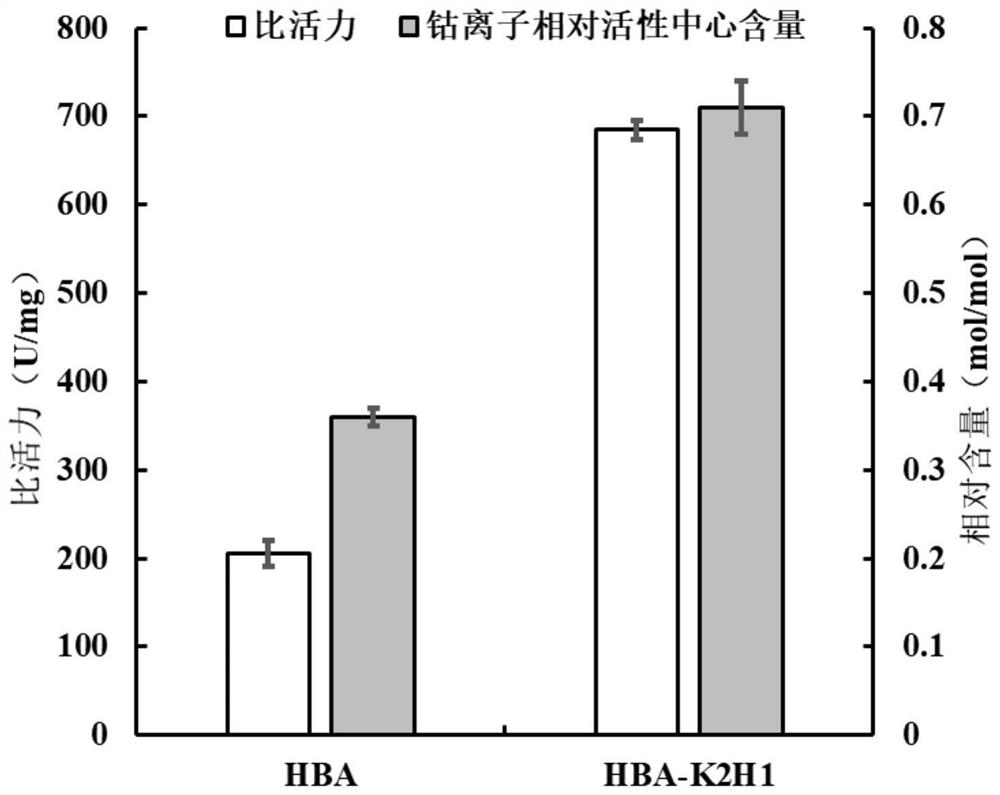

[0050] Embodiment 3: the property determination of the purified enzyme of nitrile hydratase mutant HBA-K2H1 and wild-type HBA

[0051] 1) Activity analysis of mutant HBA-K2H1 and wild-type HBA purified enzymes

[0052] Dissolve the substrate 3-cyanopyridine in 50mM boric acid-borax buffer solution (pH 8.0) to a final concentration of 10mM. After preheating the reaction solution at 40°C for 5min, add the enzyme solution to a final concentration of 3.2μg / mL, react at 40°C for 10min, then add 5M concentrated HCl

[0053] 20 μL to stop the reaction. After removing impurities by filtration with a 0.22 μm filter membrane, the amount of the product 3-pyridinecarboxamide formed was detected by HPLC. The detection condition of HPLC is to use Agilent InfinityLab Poroshell 120EC-C18 column (4.6×150mm, 4μm) chromatographic column, the column temperature is 36°C, the mobile phase is 10% (v / v) acetonitrile, and the flow rate is 0.5mL / min. The wavelength is 215nm; 1 enzyme activity unit (U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com