Method for sputtering aluminum layer on copper substrate and aluminum atom transfer copper plastic film

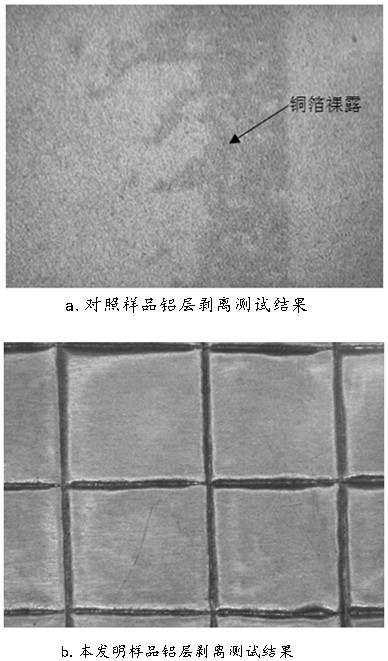

A copper substrate and sputtering technology, which is applied in sputtering plating, metal material coating process, coating, etc., can solve the difficulty of combining aluminum layer and copper layer, easy peeling off of electroplated aluminum layer, exposure of copper layer, etc. problems, to achieve the effect of low water vapor transmission rate, small number of pinholes, and ensure safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for sputtering an aluminum layer on a copper substrate. The alloy aluminum target doped with metal nickel is used as the first target, and the surface of the first target is bombarded by inert gas ions to make the first target The surface atoms overflow and deposit on the surface of the copper substrate to form a pre-shot layer; then the pure aluminum target (the purity of aluminum is 99.9999%) is used as the second target, and the surface of the second target is bombarded by inert gas ions to make the surface atoms of the second target The main body layer is formed by overflowing and covering the surface of the pre-injection layer; the pre-injection layer and the main body layer constitute an aluminum layer. The method for sputtering an aluminum layer on the copper substrate specifically comprises the following steps:

[0034] Step 1. Start the magnetron sputtering coating machine with a cold machine, load the first target and the seco...

Embodiment 2

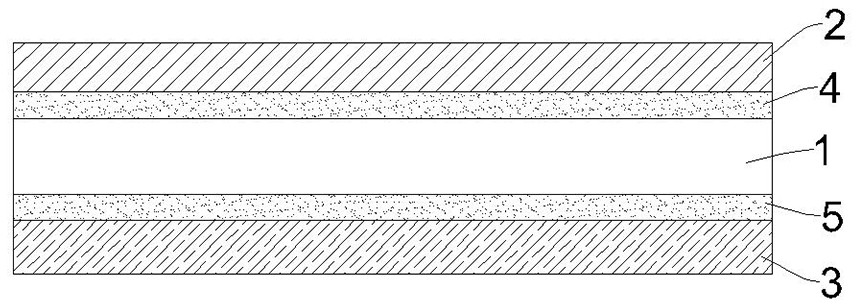

[0038] This embodiment provides an aluminum atom transfer copper-plastic film, such as figure 1 As shown, it includes a copper foil layer 1, a protective layer 2 arranged on the outside of the copper foil layer 1, and a heat-sealing layer 3 arranged on the inside of the copper foil layer 1, and a first A barrier layer 4, a second barrier layer 5 is provided between the copper foil layer 1 and the heat-sealing layer 3; the first barrier layer 4 and the second barrier layer 5 are attached to the copper foil layer by sputtering The aluminum layer on the surface of 1 has a passivation film on the surface of the aluminum layer; the surface of the first barrier layer 4 away from the copper foil layer 1 is bonded to the protective layer 2 through an adhesive, and the second barrier layer 5 The surface of the side away from the copper foil layer 1 is bonded to the heat-sealing layer 3 through an adhesive, the adhesive is maleic acid modified polypropylene; the protective layer 2 is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com