Auxiliary grid slurry suitable for back polishing surface of N-type double-sided battery

A double-sided battery, backside polishing technology, applied to conductive materials, circuits, and electrical components dispersed in non-conductive inorganic materials to achieve high-efficiency performance and good contact characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The invention is illustrated by, but not limited to, the following examples.

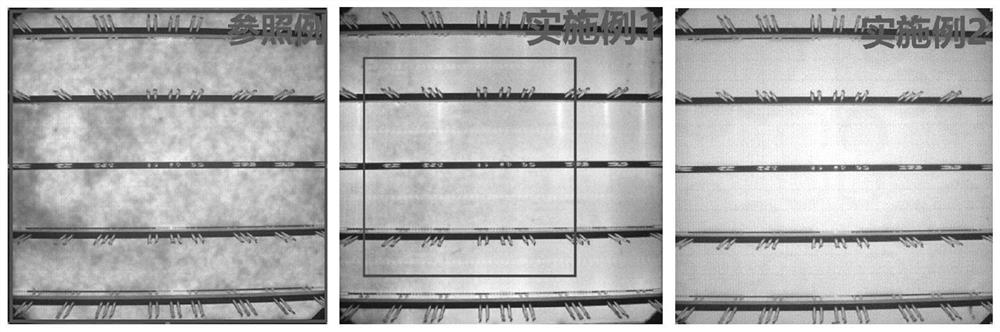

[0039] Reference group and Examples 1 to 3.

[0040] The sub-gate silver paste on the back of the N-type battery is made of the following raw materials.

[0041] Silver powder: spherical, silver powder Ag01: D(50) is 1.8-2.0um, silver powder Ag02: D(50) is 2.9-3.1um.

[0042] Glass powder: The transition temperature Tg of glass powder is 245-285°C.

[0043] Organic carrier: The proportion of total resin in the organic carrier in the examples is controlled at 6%, 9%, and 12%.

[0044] Table 1

[0045] Reference Example Carrier C Example carrier A Example Vector A2 Example Vector A3 resin content 15% 6.0% 9% 12% silicone oil 3.0% 3.0% 3.0% 3.0% other solvents etc. 82% 91.0% 88.0% 85.0%

[0046] Wherein the production method of carrier A2A3 and reference example C is the same as that of carrier A;

[0047] The reference group paste uses the cur...

Embodiment 2

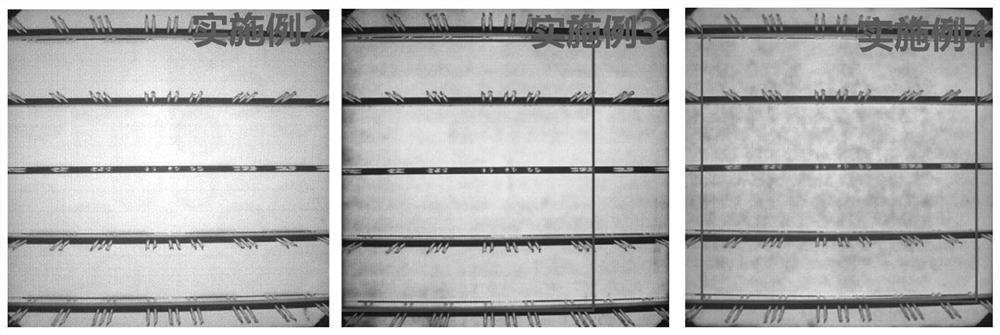

[0055] Embodiment 2 and Embodiment 3 to 4.

[0056] To test the impact of the resin content change in the carrier on the N-type backside paste, embodiment 3 uses a carrier with a resin content of 9% to match the silver powder with a large particle size; embodiment 4 uses a carrier with a resin content of 12% to match the silver powder with a large particle size. The specific formula is shown in Table 3.

[0057] table 3

[0058]

[0059]

[0060] figure 2 for the EL performance case. Table 3 and figure 2 The results show that the higher the resin content in the carrier, the more organic residues in the sintering process, the greater the impact on the flow of the glass in the slurry, the more serious the EL cloud and the worse the electrical properties, so in the case of taking into account the overall viscosity of the slurry The resin content in the carrier should be as low as possible;

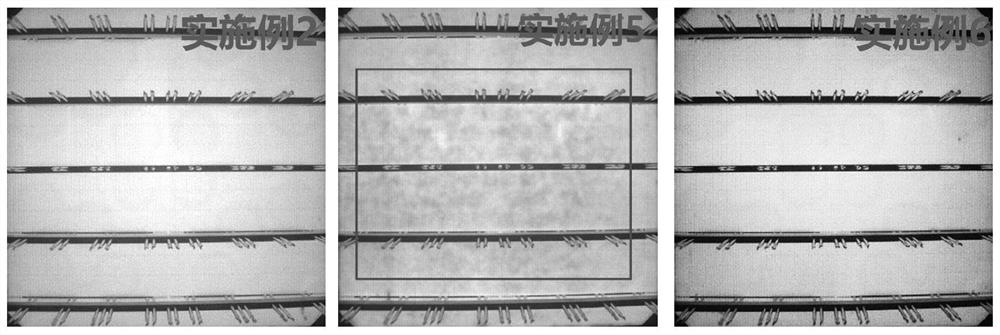

[0061] Embodiment 2 and Embodiment 5 to 6.

[0062] Check when using the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com