Lithium iron phosphate water-based positive electrode slurry, preparation method thereof and environment-friendly long-circulation lithium ion battery

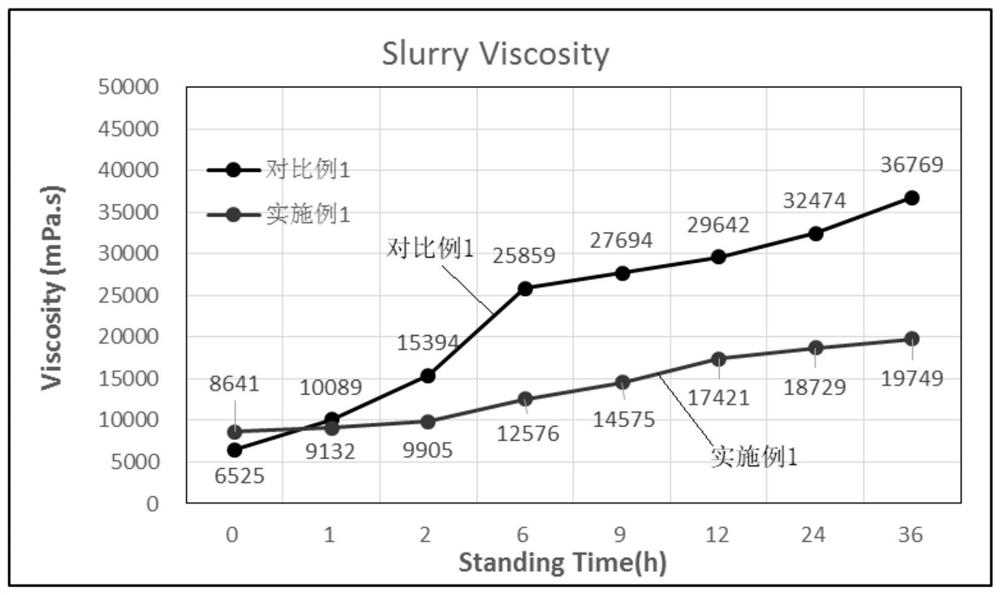

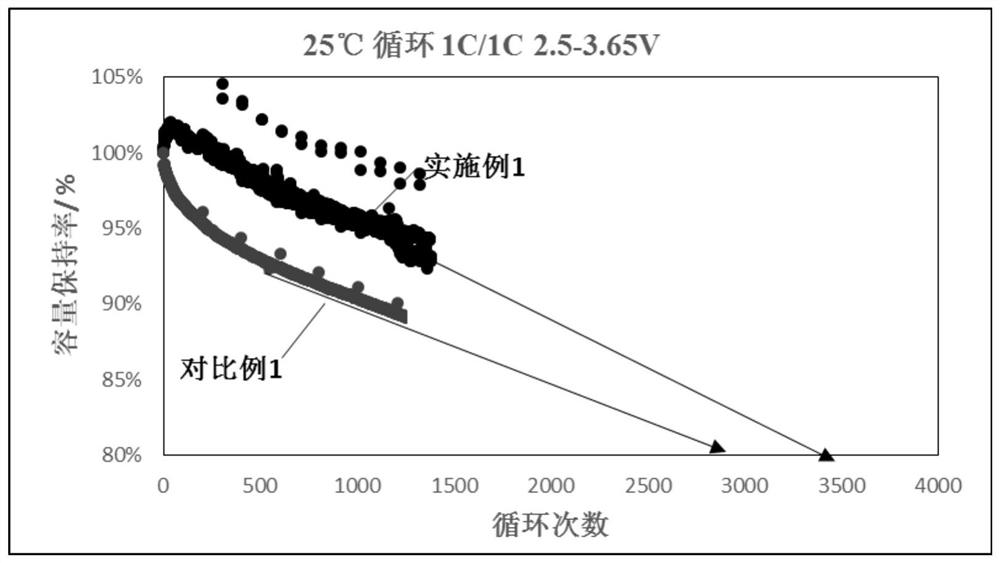

A technology of lithium iron phosphate and positive electrode slurry, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of low capacity retention rate, energy consumption, and volatile environment after 500 cycles of battery cells, and achieve improved slurry Gel phenomenon, excellent consistency, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A lithium iron phosphate aqueous cathode slurry, comprising the following raw materials in mass percentages:

[0040]Lithium iron phosphate 48.0wt%, carbon nanotube dispersion CNTs 0.35wt%, conductive carbon black 0.15wt%, PAA polyacrylic binder solution 0.65wt%, styrene-butadiene rubber emulsion SBR 0.35wt%, carboxymethyl cellulose CMC 0.5wt%, ethylene carbonate EC 2.0wt%, deionized water 48%;

[0041] Wherein the solid content of styrene-butadiene rubber emulsion SBR is 40%; the solid content of PAA polyacrylic binder solution is 6.5% model: LA133; the solid content of carbon nanotube dispersion is 6.7%;

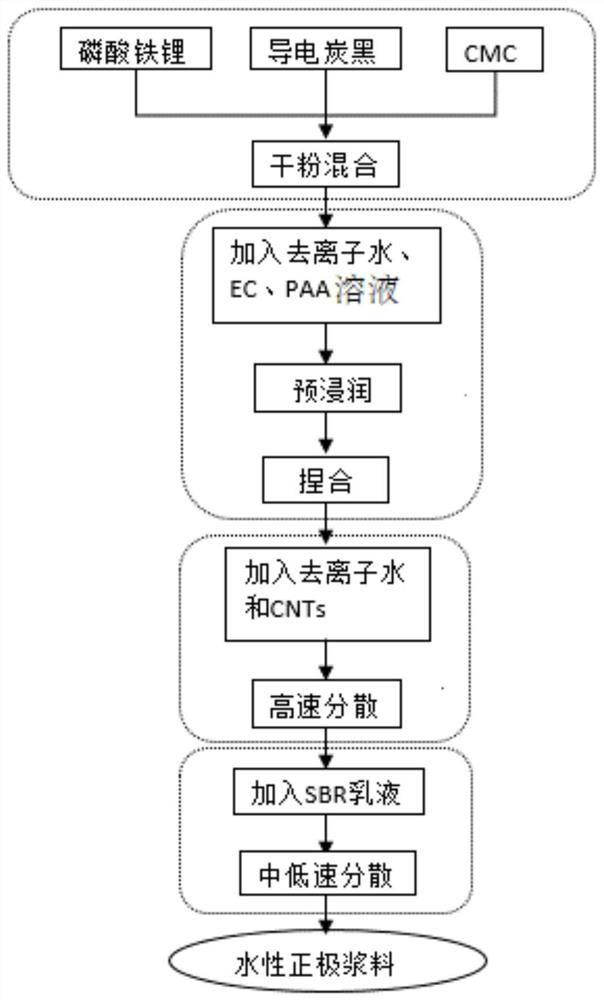

[0042] The preparation method of the above-mentioned lithium iron phosphate aqueous cathode slurry is:

[0043] 1) Prepared by ROSS 100L dual-planetary dispersive mixing machine, first dry-mix and disperse lithium iron phosphate, conductive carbon black and CMC powder according to the above ratio, parameter settings: revolution 25rmp, rotation 800rmp, time 30min; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com