Novel-structure film bulk acoustic resonator and preparation method thereof

A thin-film bulk acoustic wave and resonator technology, applied in the direction of impedance network, electrical components, etc., can solve the problems of electrical loss and low electromechanical coupling coefficient, and achieve the effect of avoiding electrical loss, high electromechanical coupling coefficient and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

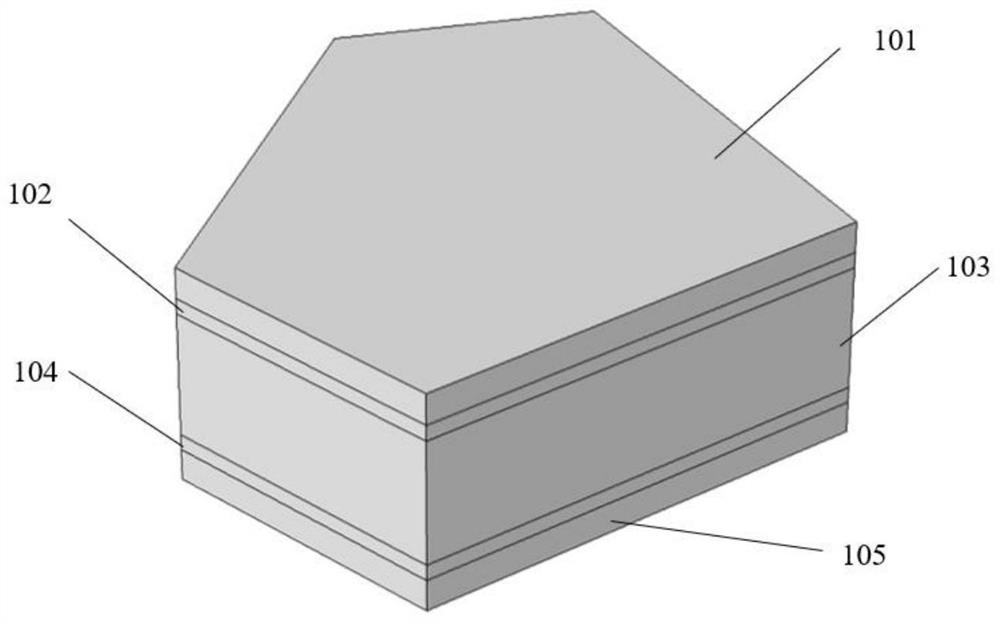

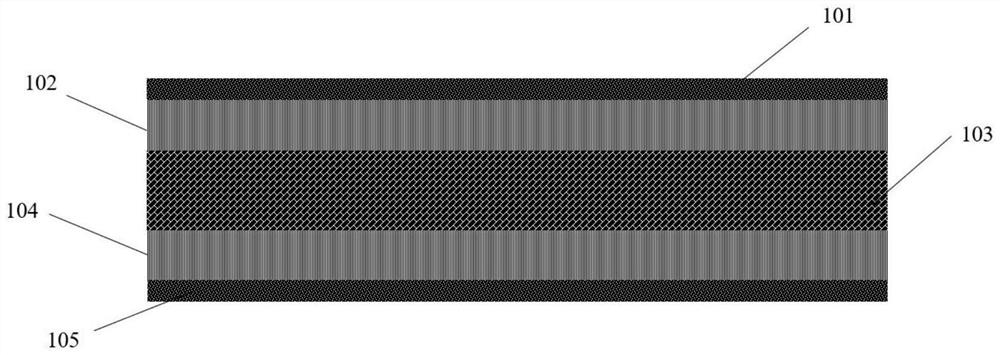

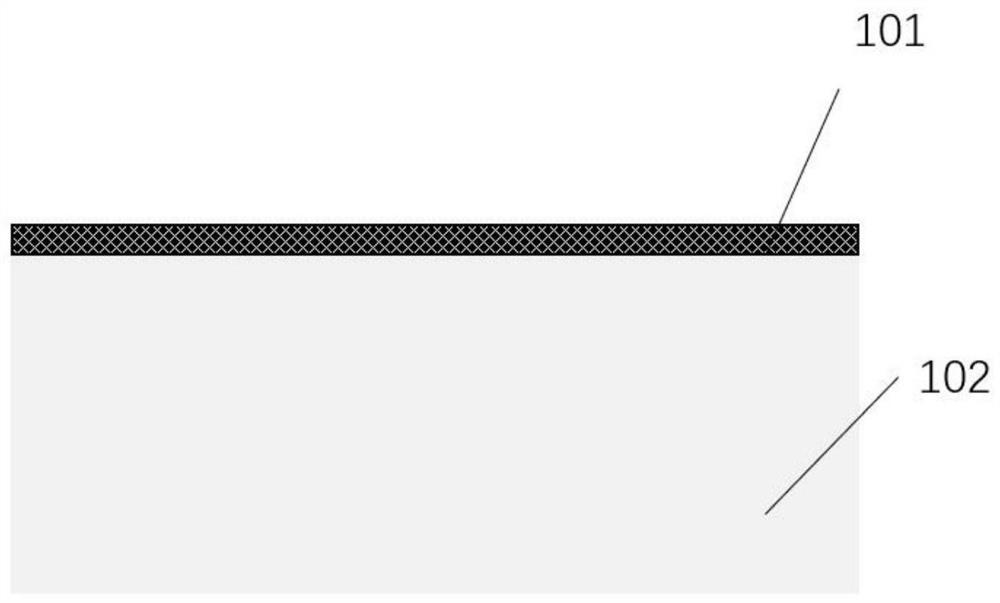

[0038] Figure 4 It is the first film bulk acoustic resonator 100 containing stacked piezoelectric materials, including: an upper electrode 101, aluminum nitride 102, scandium-doped aluminum nitride 103, and a lower electrode 104;

[0039] Wherein, aluminum nitride 102 and scandium-doped aluminum nitride 103 together constitute the piezoelectric material of the thin film bulk acoustic resonator 100;

[0040] Among them, the thickness of aluminum nitride 102 is 0.1 micron, the thickness of scandium-doped aluminum nitride is 0.8 micron; the thickness of the upper electrode and the lower electrode is 0.2 micron;

[0041] According to the COMSOL simulation results, the resonance frequency of the resonator with this structure is 2.38GHz, and the antiresonance frequency is 2.515GHz; use Matlab to calculate the quality factor and electromechanical coupling coefficient at the series and parallel resonance frequencies of the resonator, respectively: 1190, 629, 12.5336%;

[0042] It s...

Embodiment 2

[0044] Figure 5 It is the second film bulk acoustic resonator 100 containing stacked piezoelectric materials, including: an upper electrode 101, aluminum nitride 102, scandium-doped aluminum nitride 103, and a lower electrode 104;

[0045] Wherein, aluminum nitride 102 and scandium-doped aluminum nitride 103 together constitute the piezoelectric material of the thin film bulk acoustic resonator 100;

[0046] Among them, the thickness of aluminum nitride 102 is 0.2 microns, the thickness of scandium-doped aluminum nitride is 0.6 microns; the thickness of the upper electrode and the lower electrode is 0.2 microns;

[0047] According to the COMSOL simulation results, the resonance frequency of the resonator with this structure is 2.44GHz, and the antiresonance frequency is 2.564GHz; use Matlab to calculate the quality factor and electromechanical coupling coefficient at the series and parallel resonance frequencies of the resonator, respectively: 1220, 513, 11.3557%;

[0048] ...

Embodiment 3

[0050] Figure 6 It is the third thin film bulk acoustic resonator 100 containing stacked piezoelectric materials, including: an upper electrode 101, aluminum nitride 102, scandium-doped aluminum nitride 103, and a lower electrode 104;

[0051] Wherein, aluminum nitride 102 and scandium-doped aluminum nitride 103 together constitute the piezoelectric material of the thin film bulk acoustic resonator 100;

[0052] Among them, the thickness of aluminum nitride 102 is 0.3 microns, the thickness of scandium-doped aluminum nitride is 0.4 microns; the thickness of the upper electrode and the lower electrode is 0.2 microns;

[0053] According to the COMSOL simulation results, the resonance frequency of the resonator with this structure is 2.506GHz, and the antiresonance frequency is 2.617GHz; use Matlab to calculate the quality factor and electromechanical coupling coefficient at the series and parallel resonance frequencies of the resonator, respectively: 835, 291, 10.0216%;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com