Preparation method and application of craft soy sauce

A technology of soy sauce and refined brewing, which is applied in the direction of climate change adaptation, food science, and food ingredients as taste improvers, etc. It can solve the problems of reducing the volatile basic nitrogen and biological content of soy sauce, the flavor of soy sauce has not yet been seen, and the price is relatively expensive. , to achieve the effect of improving the overall flavor, reducing the salty taste and improving the umami taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) After soybean is mixed with wheat flour of the same weight after cooking treatment, the mixture is obtained. The temperature of the cooking treatment is 120°C, and the time of cooking treatment is 30min. The mass is 0.02% (w / w) of the mass of the mixture, and the koji is made. The temperature of the koji is 28°C, the humidity of the koji is 90%, and the time of the koji is 72h, and Daqu is obtained;

[0040] (2) Daqu is mixed with salt water (NaCl solution, the concentration is 20%), the volume of salt water is 2.2 times of the volume of Daqu, and the high-salt dilute soy sauce brewing method (GB18186-2000) is used in the fermenter to ferment, During the period of 30 days to 180 days, carry out vacuum treatment on the top of the soy sauce fermentation tank (vacuum treatment is carried out 3 times a month), and each time the vacuum treatment reduces the air pressure at the top of the soy sauce fermentation tank to 700 mm Hg. The time of vacuum treatment is 6 hours. A...

Embodiment 1

[0042] (1) After soybean is mixed with wheat flour of the same weight after cooking treatment, the mixture is obtained. The temperature of the cooking treatment is 120°C, and the time of cooking treatment is 30min. The mass is 0.02% (w / w) of the mass of the mixture, and the koji is made. The temperature of the koji is 28°C, the humidity of the koji is 90%, and the time of the koji is 72h, and Daqu is obtained;

[0043] (2) Daqu is mixed with salt water (NaCl solution, the concentration is 20%), the volume of salt water is 2.2 times of the volume of Daqu, and the high-salt dilute soy sauce brewing method (GB18186-2000) is adopted in the fermenter to ferment, and the fermentation is 180 Tianhou heat treatment to kill bacteria and enzymes, squeeze and filter to obtain the soy sauce stock solution.

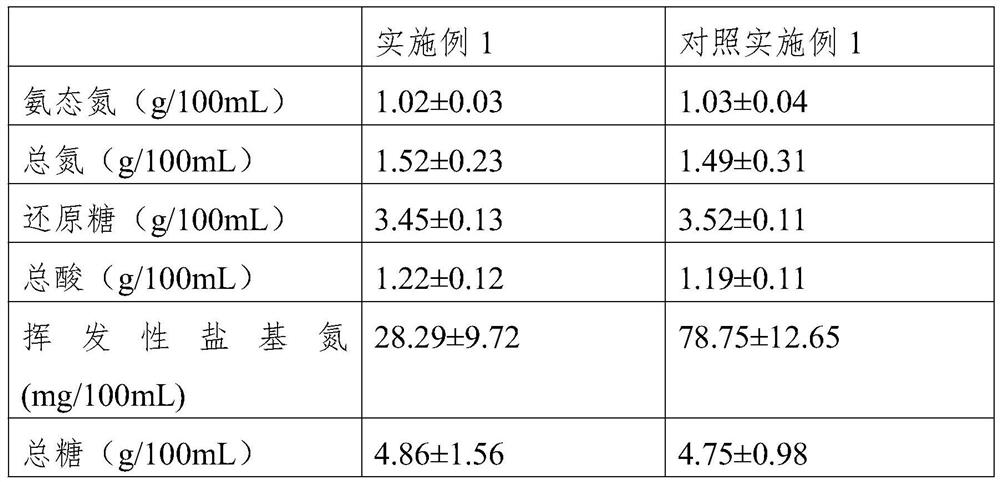

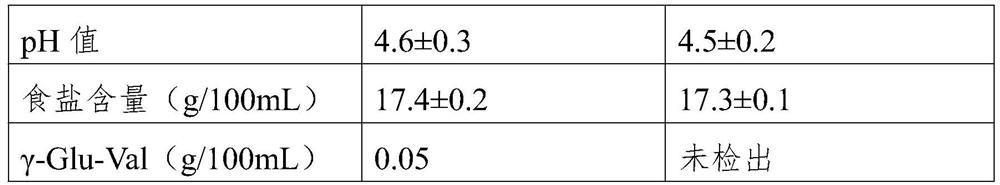

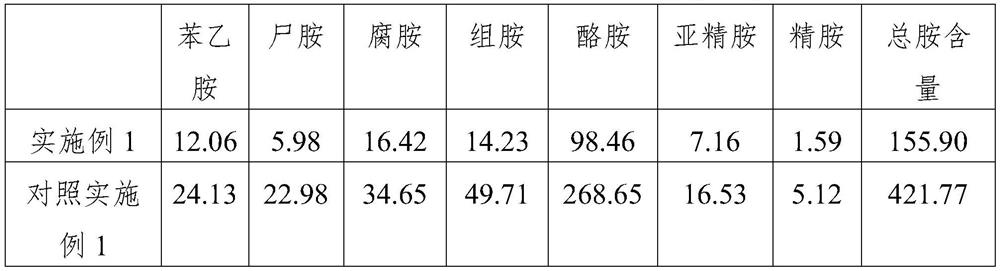

[0044] The obtained soy sauce crude oil of embodiment 1 and comparative example 1 is measured ammoniacal nitrogen, total nitrogen, reducing sugar, total acid, volatile base nitrogen, ...

Embodiment 2

[0063] (1) After soybean is mixed with wheat flour of the same weight after cooking treatment, the mixture is obtained. The temperature of the cooking treatment is 130°C, and the time of cooking treatment is 15min. The mass is 0.05% (w / w) of the mixture mass, and the koji is made. The temperature of the koji is 30° C., the humidity of the koji is 90%, and the time of the koji is 42 hours, and Daqu is obtained;

[0064] (2) Daqu is mixed with salt water (NaCl solution, the concentration is 24%), the volume of salt water is 2.5 times of the volume of Daqu, and the high-salt dilute soy sauce brewing method (GB18186-2000) is adopted in the fermenter to ferment. During the period of 30 days to 150 days, carry out vacuum treatment on the top of the soy sauce fermentation tank (vacuum treatment once a month), each time the vacuum treatment reduces the air pressure at the top of the soy sauce fermentation tank to 500 mm Hg, each time The time of vacuum treatment is 3 hours. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com