Method for removing acetic acid from DMF solution of sucrose-6-ethyl ester

A technology of acetic acid and solution, applied in separation methods, chemical instruments and methods, sugar derivatives, etc., can solve problems such as increased processing difficulty, raw material consumption cost, complicated separation process, and difficult to handle solid reaction products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

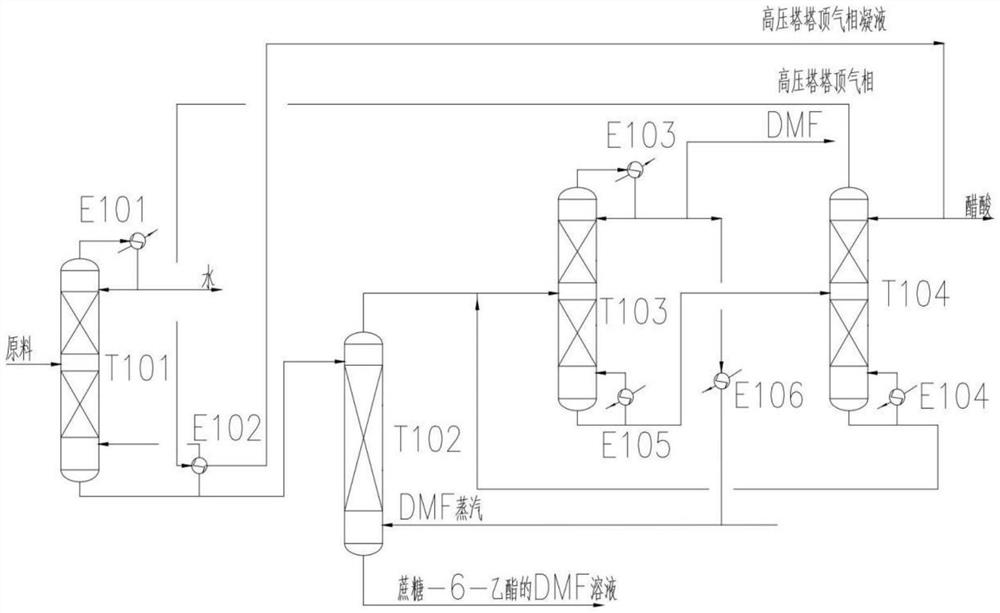

Image

Examples

Embodiment 1

[0030] (1) The sucrose-6-ethyl ester solution containing DMF, acetic acid and water is sent to the dehydration tower T101 for rectification, and the total feed rate is 1000kg / hr. The operating pressure of the dehydration tower T101 is -0.095Mpa, and the operating temperature is 78°C. The condensate at the top of the tower is withdrawn as waste water. The tower still liquid phase is connected to the tower still reboiler for vaporization, and part of the tower still liquid is sent to the T102 stripping tower.

[0031] (2) The discharge from the T101 tower kettle enters the top of the stripper T102 tower, and the steam of DMF is introduced into the bottom of the stripper tower, and the gas and liquid are countercurrently contacted in the tower. The operating pressure of the stripper T102 is -0.095Mpa, and the operating temperature is 56 ℃. The sucrose-6-ethyl ester solution containing DMF is obtained from the bottom of the stripping tower T102, and the mixture of DMF and acetic...

Embodiment 2

[0035] (1) The sucrose-6-ethyl ester solution containing DMF, acetic acid and water is sent to the dehydration tower T101 for rectification, and the total feed rate is 1000kg / hr. The operating pressure of the dehydration tower T101 is -0.099Mpa, and the operating temperature is 60°C. The condensate at the top of the tower is withdrawn as waste water. The tower still liquid phase is connected to the tower still reboiler for vaporization, and part of the tower still liquid is sent to the T102 stripping tower.

[0036] (2) The discharge from the T101 tower kettle enters the top of the stripper T102 tower, and the steam of DMF is passed into the bottom of the stripper tower, and the gas-liquid contacts in countercurrent in the tower. The operating pressure of the stripper T102 is 0 MPa, and the operating temperature is 90 ° C. The sucrose-6-ethyl ester solution containing DMF is obtained from the bottom of the stripping tower T102, and the mixture of DMF and acetic acid is extrac...

Embodiment 3

[0040] (1) The sucrose-6-ethyl ester solution containing DMF, acetic acid and water is sent to the dehydration tower T101 for rectification, and the total feed rate is 1000kg / hr. The operating pressure of the dehydration tower T101 is -0.09Mpa, and the operating temperature is 80°C. The condensate at the top of the tower is withdrawn as waste water. The tower still liquid phase is connected to the tower still reboiler for vaporization, and part of the tower still liquid is sent to the T102 stripping tower.

[0041] (2) The discharge from the T101 tower kettle enters the top of the stripper T102 tower, and the steam of DMF is passed into the bottom of the stripper tower, and the gas-liquid contacts in countercurrent in the tower. The operating pressure of the stripper T102 is 0 MPa, and the operating temperature is 90 ° C. The sucrose-6-ethyl ester solution containing DMF is obtained from the bottom of the stripping tower T102, and the mixture of DMF and acetic acid is extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com