A kind of nanocellulose/sodium alginate cryogel and its preparation method and application

A technology of nanocellulose and cryogel, applied in the field of sodium alginate, can solve the problems of poor mechanical properties, slowness, and insufficient chemical crosslinking of cryogel, and achieve good adsorption and purification performance, wide sources, and good biophase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Specifically, the preparation method of the nanocellulose / sodium alginate cryogel comprises the following steps:

[0032] (1) adding sodium alginate to the nanocellulose suspension with a mass concentration of 0.10 to 0.75 wt %, stirring until it is completely dissolved, to obtain a mixed solution with a mass concentration of sodium alginate of 1.0 to 2.5 wt %;

[0033] (2) adjusting the pH value of the mixed solution obtained in step (1) to 11.0-13.0, adding vinylsulfone until its mass concentration in the mixed solution is 1.00-1.75wt%, stirring, and then placing the mixed solution in -12- Continue the reaction for more than 12h at -20°C;

[0034] (3) After the reaction in step (2) is completed, thaw and wash at room temperature to obtain nanocellulose / sodium alginate cryogel.

[0035] Preferably, wherein the nanocellulose is cellulose nanofibers or cellulose nanocrystals.

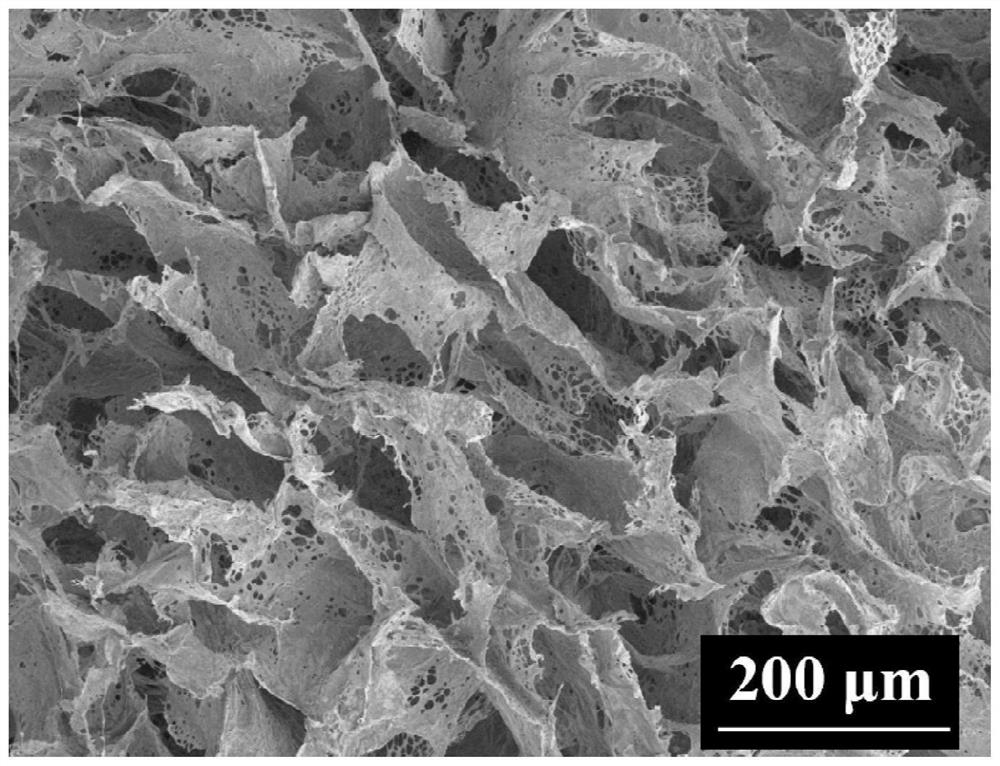

[0036] It was confirmed by scanning electron microscopy that the nanocellulose / sodium algina...

Embodiment 1

[0040](1) get 0.5g sodium alginate in 20mL 0.75wt% cellulose nanofibers (sodium alginate is 2.5% of the total solution mass), utilize a high-speed stirrer to stir until completely dissolved;

[0041] (2) Adjust the pH value of the obtained mixed solution to 11.0, add 0.35 mL of vinyl sulfone (vinyl sulfone is 1.75% of the total mass of the solution), stir, pour it into a mold and place it in a -12°C low-temperature test box to react for 12 hours;

[0042] (3) Take out the cryogel, thaw it at room temperature, and wash with a large amount of distilled water to prepare a nanocellulose / sodium alginate cryogel.

[0043] figure 1 The scanning electron microscope image of the nanocellulose / sodium alginate cryogel prepared in this example is shown. Interconnected macropores and lamellar pore walls of tens of micrometers can be observed from the SEM images. In particular, there are many irregular small pores on the walls, and the diameters of these pores are about 3 to 7 μm, which me...

Embodiment 2

[0053] (1) get 0.5g sodium alginate in 20mL 0.10wt% cellulose nanofibers (sodium alginate is 2.5% of the total solution mass), utilize a high-speed stirrer to stir until completely dissolved;

[0054] (2) Adjust the pH value of the obtained mixed solution to a range of 11.0, add 0.35 mL of vinyl sulfone (vinyl sulfone is 1.75% of the total mass of the solution), stir, pour it into a mold and place it in a -12°C low-temperature test box to react for 12 hours;

[0055] (3) Take out the cryogel, thaw it at room temperature, and wash with a large amount of distilled water to prepare a nanocellulose / sodium alginate cryogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com