A kind of super-tough self-healing epoxy resin glass polymer material and preparation method thereof

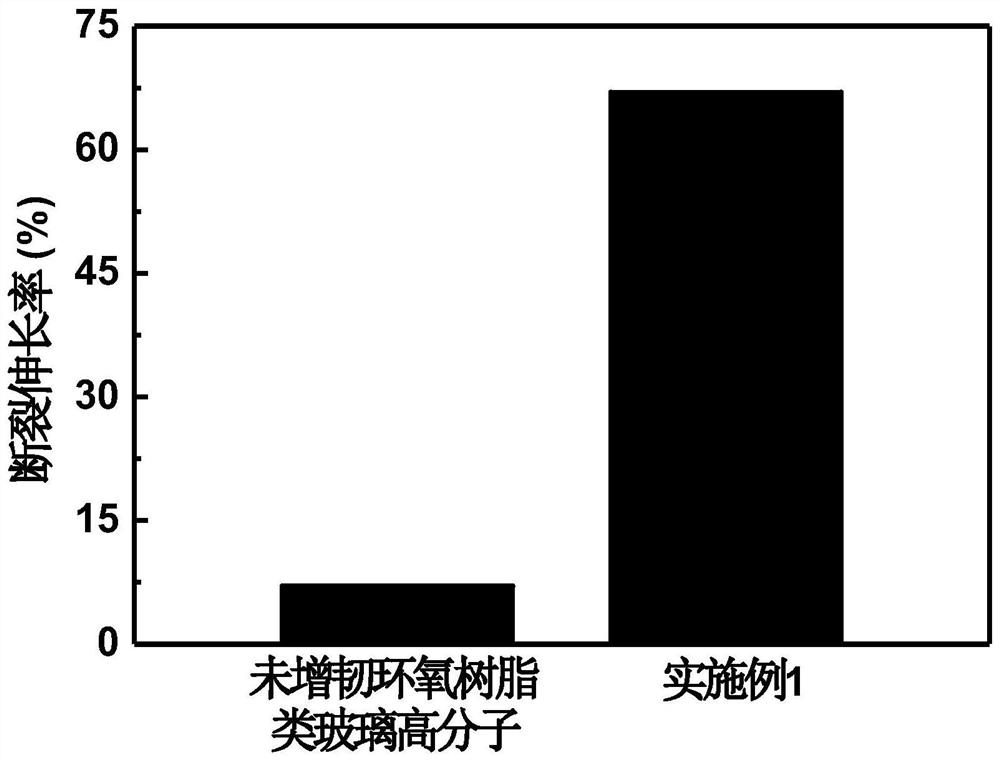

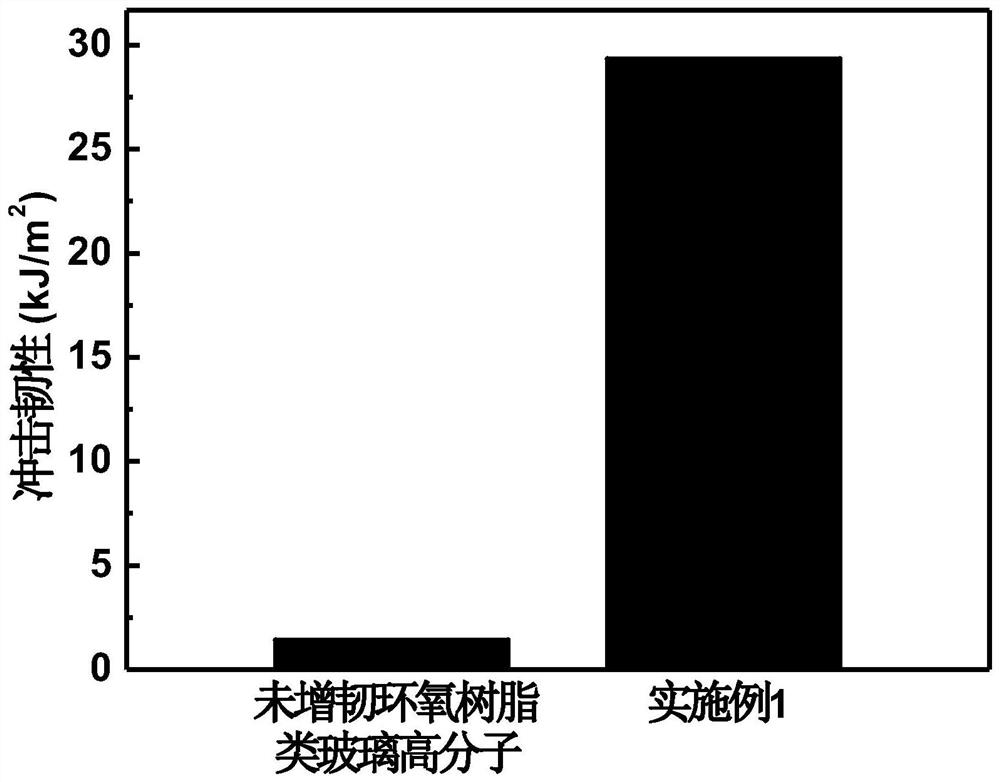

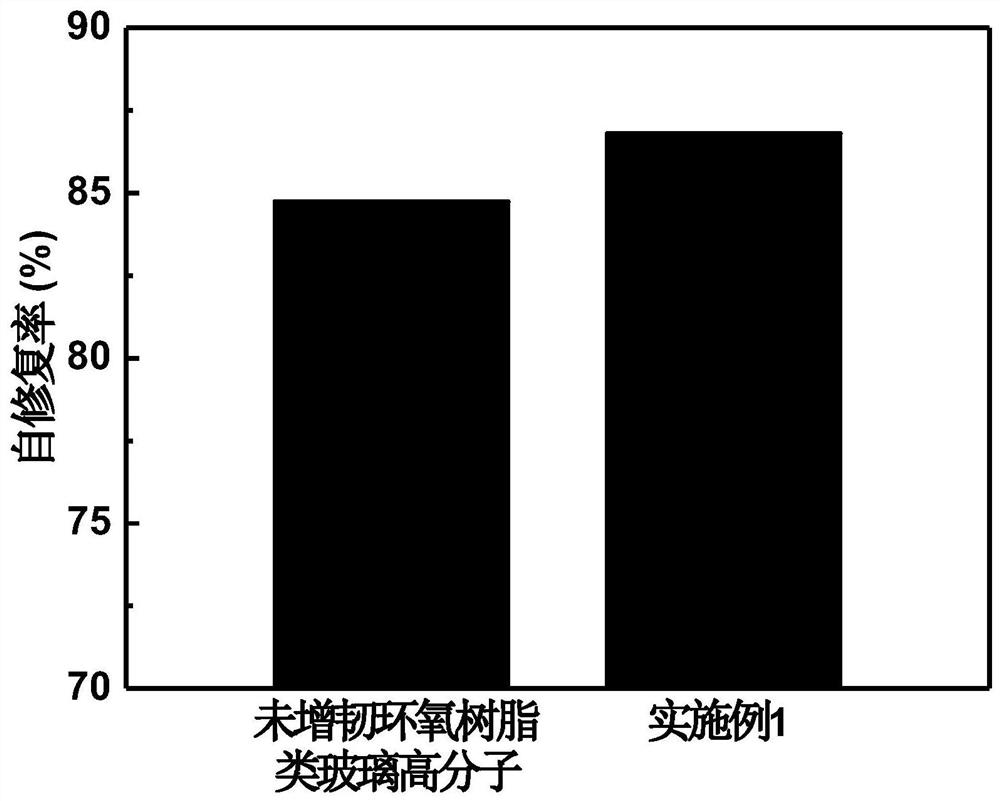

A polymer material and epoxy resin technology, applied in the field of thermosetting materials, can solve the problems of high brittleness, difficult to recycle, and catalyst type glass-like polymer is not environmentally friendly, and achieves a controllable degree, good compatibility, and good self-healing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for toughening catalyst-free epoxy resin glass polymers by using polysebacic anhydride and improving comprehensive properties such as elongation at break, impact toughness, self-repair efficiency and thermal stability, the specific steps are as follows:

[0041] 1. Preparation of Catalyst-free Super Tough Epoxy Glass Polymer

[0042] 1) Preheat 40g of epoxy resin at 120°C for 10min;

[0043] 2) Add 23.3g of glutaric anhydride and 14.1g of terephthalic acid to the epoxy resin until it is completely dissolved, then vacuumize and remove air bubbles, stir and mix evenly;

[0044] 3) 4g (in this embodiment, the content of polysebacic anhydride accounts for 10% of the mass ratio of epoxy resin) polysebacic anhydride is added to the system until it is uniformly mixed;

[0045] 4) Casting the mixture, curing at a curing temperature of 130° C. to 220° C. for 10 hours to obtain a catalyst-free super-tough self-healing epoxy resin glass polymer material.

[0046] A 5967...

Embodiment 2

[0049] A method for toughening catalyst-free epoxy resin glass polymers by using polysebacic anhydride and improving comprehensive properties such as elongation at break, impact toughness, self-repair efficiency and thermal stability, the specific steps are as follows:

[0050] 1. Preparation of Catalyst-free Super Tough Epoxy Glass Polymer

[0051] 1) Preheat 40g of epoxy resin at 120°C for 10min;

[0052] 2) Add 23.3g of glutaric anhydride and 14.1g of terephthalic acid to the epoxy resin until it is completely dissolved, then vacuumize and remove air bubbles, stir and mix evenly;

[0053] 3) 10g (in this embodiment, the content of polysebacic anhydride accounts for 25% of the mass ratio of epoxy resin) polysebacic anhydride is added to the system until it is uniformly mixed;

[0054] 4) Casting the mixture, and curing it at a curing temperature of 130° C. to 220° C. for 10 hours to obtain a catalyst-free super-tough epoxy resin glass polymer material.

[0055] A 5967 Inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com