Special efficient foam cleaning disinfectant for farms

A disinfectant and farm technology, applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of incomplete killing, damage to disinfection objects, fast flow speed, etc. Rich and delicate foam, reducing pathogen concentration, fine and uniform foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

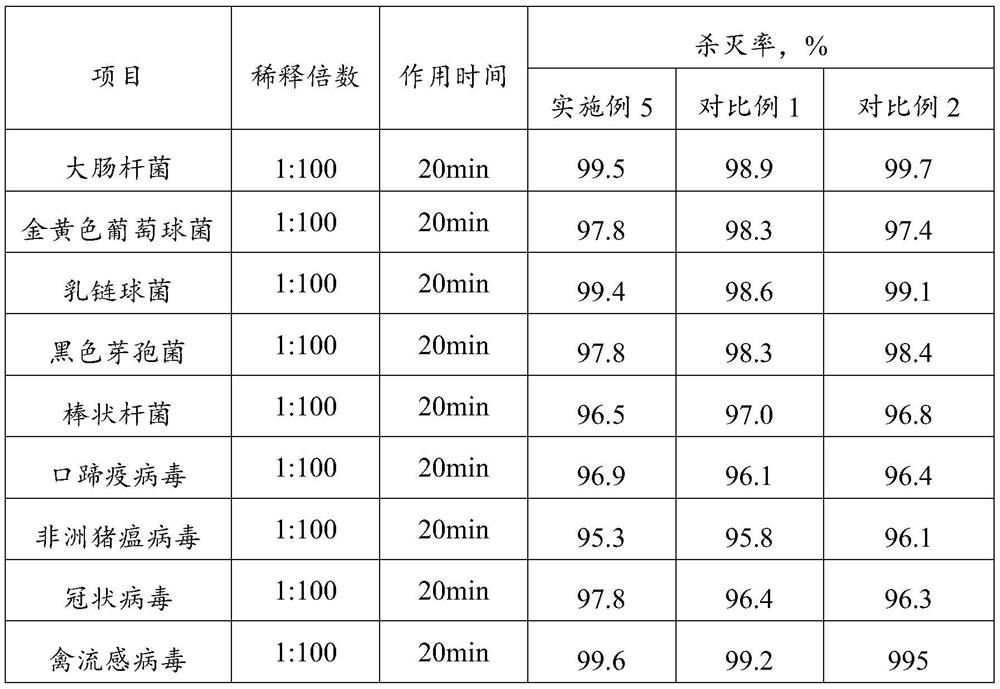

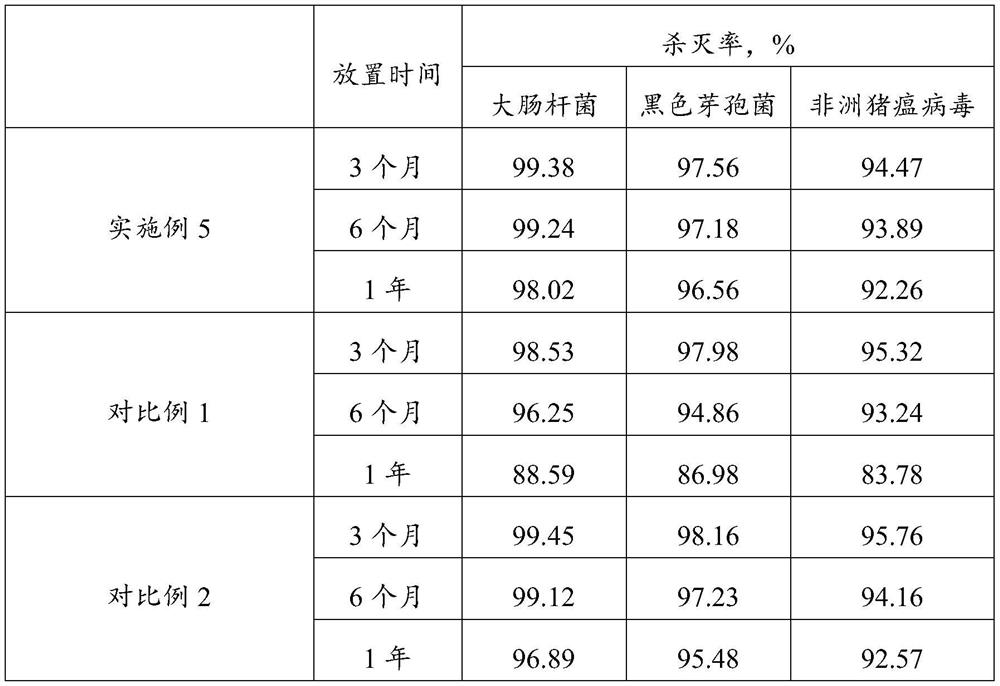

Examples

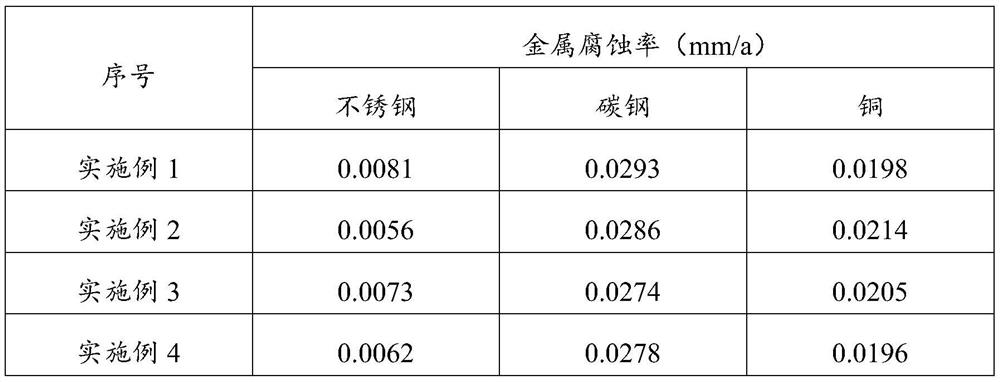

Embodiment 1

[0034] The preparation method of a high-efficiency foam cleaning and disinfecting agent for farms is as follows: 72g of sodium α-olefin sulfonate, 380g of AOS surfactant, 150g of sodium alkylbenzenesulfonate and 150g of lauramide propylamine oxide are mixed and stirred evenly , to obtain the mixture, set aside; add 190mL deionized water to 100g sodium hydroxide, place in the batching tank and stir for 3min, then add 100g sodium hydroxide, then add anhydrous citric acid and EDTA with a mass ratio of 1.5:1 The compounded 18g complexing agent is closed after stirring for 3 minutes, and the temperature is naturally cooled overnight; the next day, check whether the sodium hydroxide in the batching tank is completely dissolved, and if there is precipitation, open it for 3 minutes before confirming; confirm the dissolved hydroxide Add sodium to the mixture mixed the day before yesterday, add 30g of anti-corrosion agent, and stir for 5 minutes to prepare a high-efficiency foam cleaning...

Embodiment 2

[0037] A kind of preparation method of the high-efficiency foam cleaning disinfectant special for farm is: 95g of α-alkenyl sodium sulfonate, AOS surfactant 320g, primary alkyl sodium sulfonate 190g and 200g betaine BS-12 are mixed and stirred evenly, Obtain the mixture and set it aside; add 170mL deionized water to 80g of sodium hydroxide, place it in the batching tank and stir for 3min, then add 80g of sodium hydroxide, then add anhydrous citric acid and EDTA compounded with a mass ratio of 3:1 The prepared 25g complexing agent, after stirring for 3 minutes, close it, and let it cool down naturally overnight; the next day, check whether the sodium hydroxide in the batching tank is completely dissolved, and if there is precipitation, open it for 3 minutes before confirming; confirm the dissolved sodium hydroxide Add the mixture that was mixed the day before yesterday, add 10g of anti-corrosion agent, and stir for 5 minutes to prepare a high-efficiency foam cleaning and disinfe...

Embodiment 3

[0040] A kind of preparation method of high-efficiency foam cleaning disinfectant special for farms is: mix 78g of sodium α-alkenyl sulfonate, 360g of AOS surfactant, 180g of alcohol ether sulfuric acid and 160g of dodecylalanine and mix evenly to obtain The mixture is set aside; add 180mL of deionized water to 95g of sodium hydroxide, place it in the batching tank and stir for 3 minutes, then add 95g of sodium hydroxide, and then add anhydrous citric acid and EDTA with a mass ratio of 1.8:1 to compound The resulting 10g complexing agent was stirred for 3 minutes and then closed, and the temperature was naturally cooled overnight; the next day, check whether the sodium hydroxide in the batching tank is completely dissolved, and if there is precipitation, open it for 3 minutes before confirming; confirm that the dissolved sodium hydroxide is added Add 22g of anti-corrosion agent to the mixture mixed the day before yesterday, and stir for 5 minutes to prepare a high-efficiency fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com