Ion type rare-earth ore leaching mother solution impurity-removal system and method

A technology of ionic rare earth ore and mother liquor, which is applied in the field of positioning, can solve the problems of large floor area, long aging time, and large amount of flocculant in the mother liquor treatment workshop, so as to reduce impurities and product settling time, and reduce impurity removal of rare earth Loss, the effect of reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

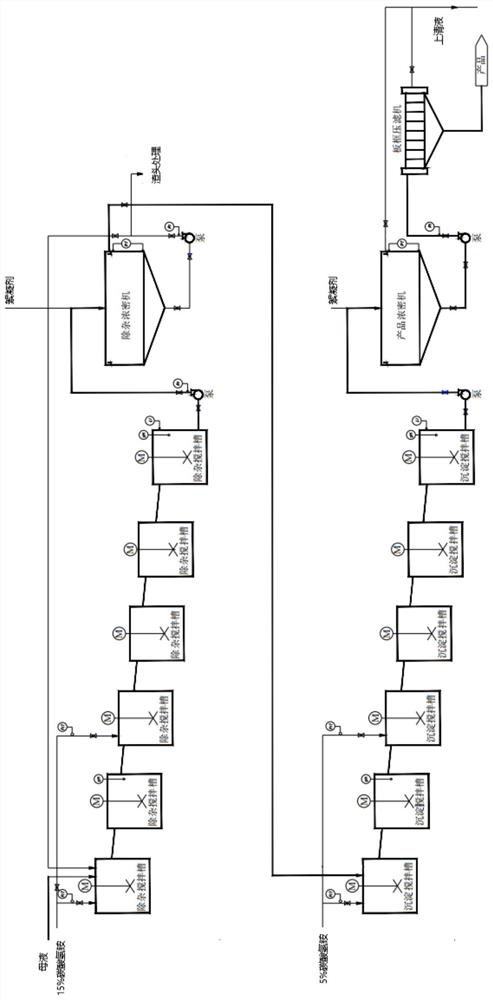

[0107] 5~25g / L (NH 4 ) 2 SO 4 The solution leaches ionic rare earth ores in situ at a pH value of 4.0-4.5 at room temperature, and the collected rare earth leach solution has a REO content of 0.1-1.5g / L, and main impurity components: Al 108-292mg / L, Fe 7-20mg / L, its heavy metal content is very low.

[0108] The mother liquor is added to the multi-stage serial impurity removal stirring module for stirring, the pH value of the second stage is controlled to 5.2, and the pH value of the sixth stage is controlled to 5.4. Add 50g / L NH 4 HCO 3 The solution was kept in the reaction tank for a residence time of 60 min.

[0109] When removing impurities, the amount of flocculant added is 0.5g / m 3 , the settling velocity after adding flocculant is 31.4mm / min. The supernatant Al obtained by removing impurities is 5.45mg / L, and the removal efficiency of impurities is 98%.

[0110] The pH value of the second stage of the multi-stage series precipitation stirring module is controlle...

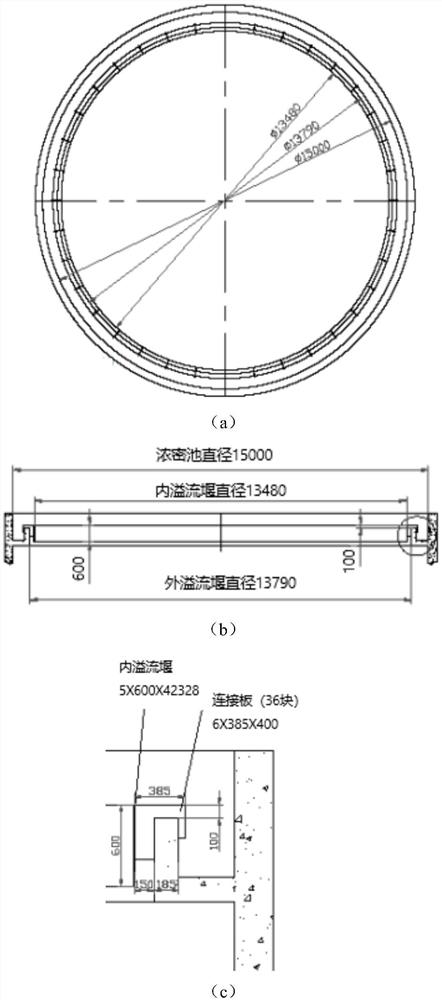

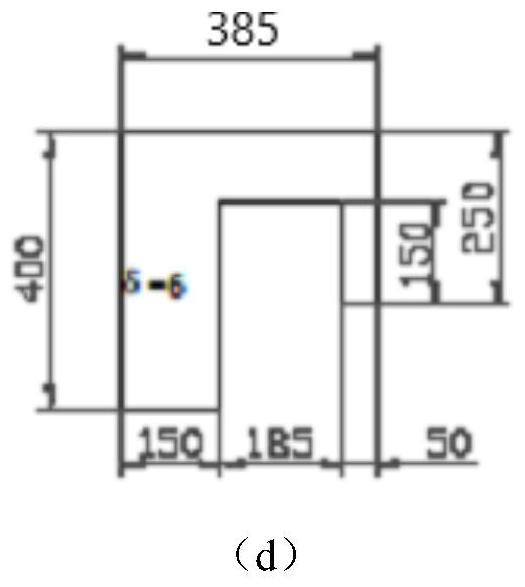

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com