BOG comprehensive utilization system for LNG receiving station

A receiving station and entrance technology, which is applied in the pipeline system, liquid bottling, packaging items, etc., can solve the problems of resource waste and adverse environmental impact, reduce energy loss and waste, realize cascade utilization, and improve energy utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

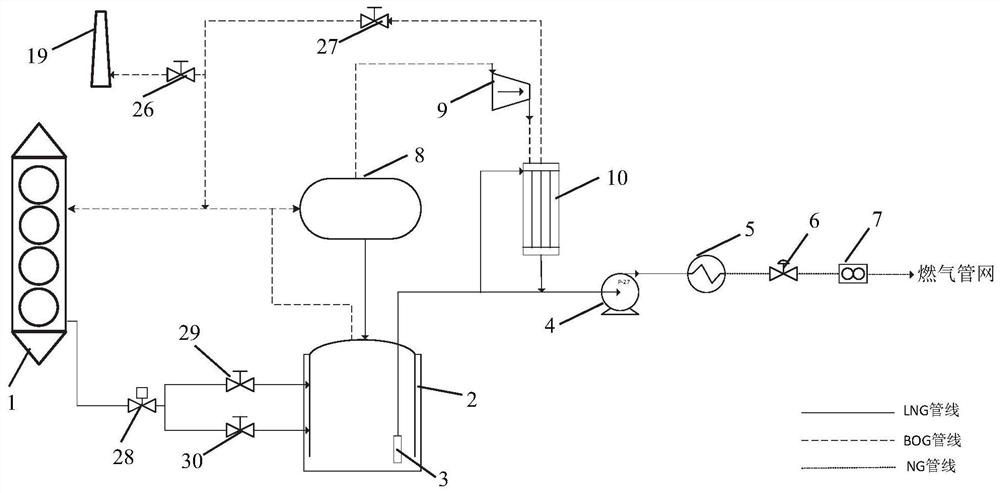

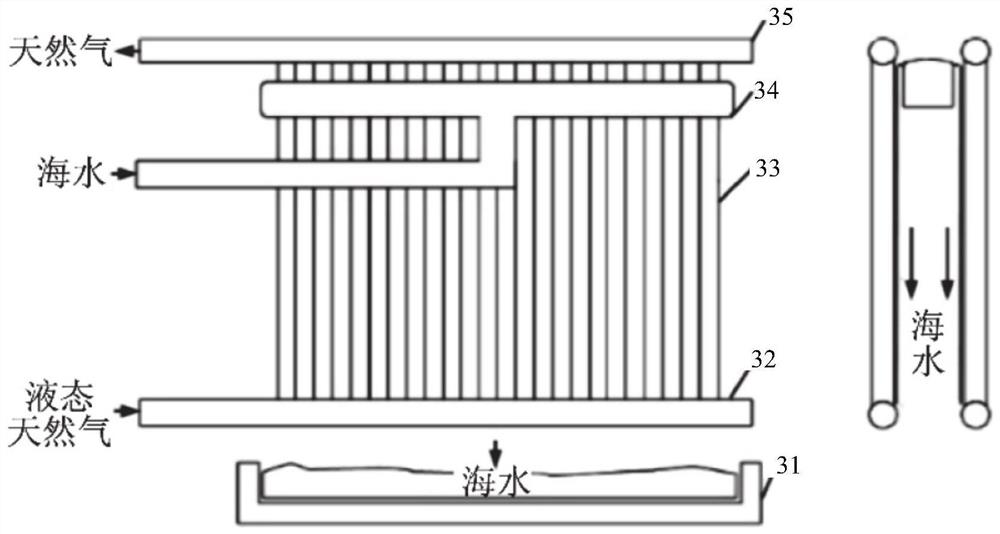

[0031] 1. An LNG receiving station BOG comprehensive utilization system, including: LNG transport boat 1, LNG tank 2, potential pump 3, high pressure pump 4, vaporizer 5, voltage regulator A6, metering device A7, buffer can 8, BOG compressor 9, re-condenser 10, seawater pump 11, heat exchanger A12, heat exchanger B13, power generating device 16, lithium bromide 17, waste heat boiler 18, torch 19 and multiple valves;

[0032] LNG transport ship 1 export pipe connection LNG storage tank 2 inlet, LNG storage tank 2 outlet connection buffer can 8 inlet, buffer can 8 outlet connection BOG compressor 9 inlet, BOG compressor 9 outlet connection reconductor 10 inlet; LNG storage The can 2 has a potential pump 3, the outlet airway of the sub-potential pump 3 is connected to the re-condenser 10; the re-condenser 10 is applied to the high pressure pump 4 inlet, the high pressure pump 4 outlet connection vaporizer 5 inlet, the vaporizer 5 outlet connection regulation A6 entrance, voltage regu...

Embodiment 2

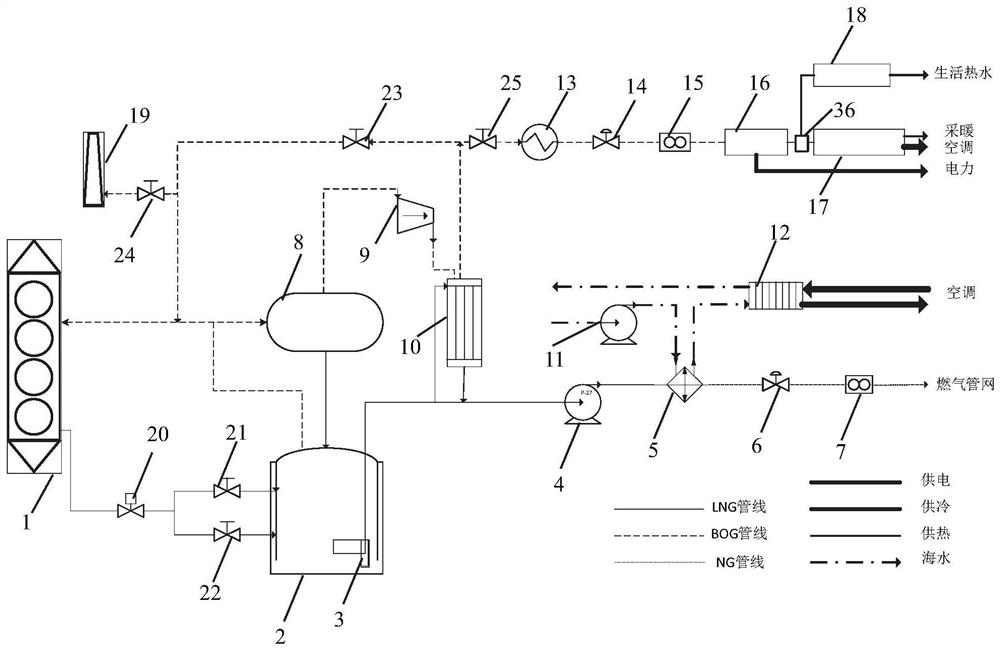

[0036] Such as figure 2 As shown, a method of working use of the LNG receiving station BOG comprehensive utilization system is:

[0037] LNG unloading operating conditions, when the discharge from the LNG transport ship 1 enters the LNG storage tank 2, the flash generates a quantity of BOG, so that the pressure of the LNG storage tank 2 increases, and the partial BOG will return to the LNG through the gas phase return pipe. On the boat, part -150 ° C, 115 kPa of BOG enters the buffer can 8, and the re-condenser 10 is entered after pressurizing to 1800 kPa via the BOG compressor 9. -161.00 ° C, 115 kPa LNG was pressurized to 550 kPa to 550 kPa into the recondensator 10, and the ultra-cold state liquefied liquefied, liquefied LNG and the LNG flowing out of the sub-liquid pump 3 were added. Pressure to 6500 kPa, the temperature increases to -135 ° C to enter the ORV vaporizer 5, and the LNG enters the urban gas pipe network after the modulator A6 and the metrological device A7 are tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com