Flexible interdigital capacitive sensor structure and preparation method thereof

An interdigital capacitance and sensor technology, which is applied in the field of flexible electronic equipment, can solve the problems of lack of preparation and performance research of flexible interdigital sensors, lack of sensor parameter sensor performance characterization, long preparation time of flexible interdigital sensors, etc., to achieve low cost, Thin and light appearance, the effect of improving the response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

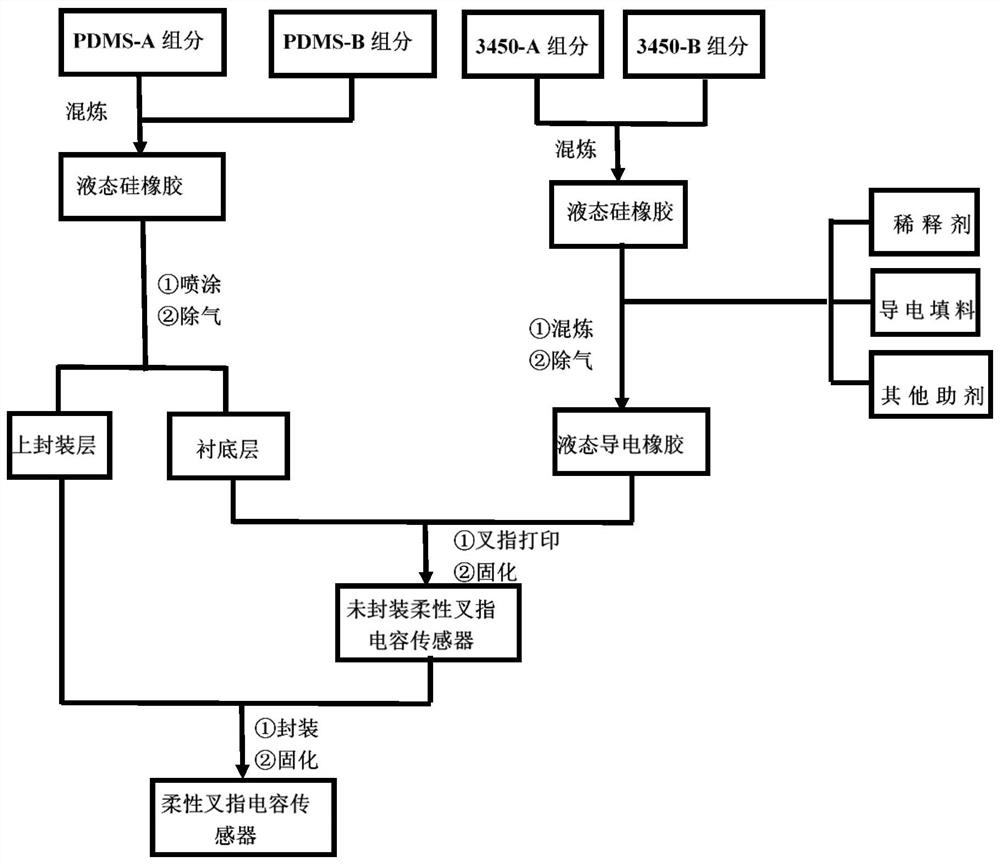

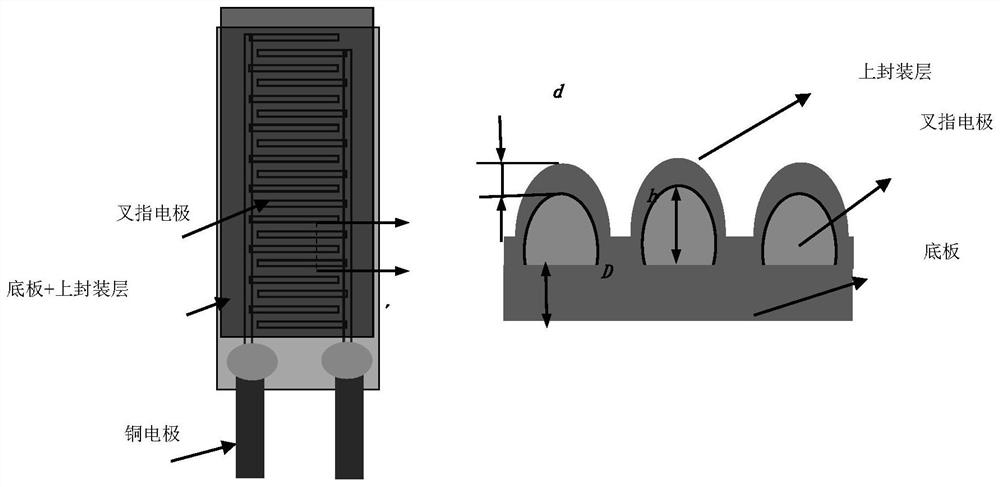

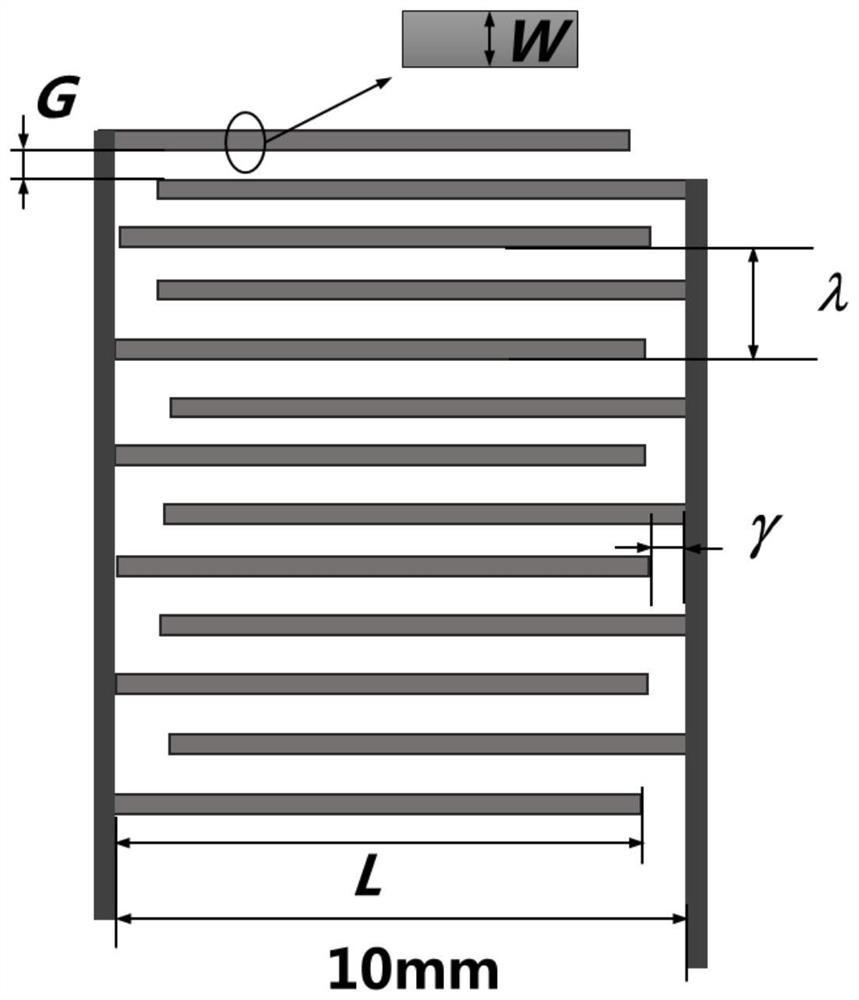

[0050] Example 1: The formula of liquid silicone rubber used as the substrate of the flexible finger capacitive sensor and the upper packaging layer is mixed with 85wt% PDMS prepolymer and 15wt% curing agent Dow Corning 184B, and the viscosity after mixing is 1724mPa·s; it is used as a flexible finger The conductive rubber formula of the interdigital electrode layer of the capacitive sensor is 44wt% liquid silicone rubber (vinyl-terminated polydimethylsiloxane, 15Pa.s, density 1.2g / cm 3 ), 25wt% silver-plated glass fiber (silver plating amount 18wt%, aspect ratio 200μm: 8μm), 6wt% carbon fiber (aspect ratio 120μm: 8μm), 20wt% diluent (simethicone) and 5wt% synergistic Agents (1,2-propanediol) were mixed uniformly in order. Prepare according to the following steps: ①Preparation of the base layer, put the mixed liquid silicone rubber into the spray gun, spray it on the PET under the pressure of 0.6MPa to form a film, and further carry out vacuum degassing under the environment o...

Embodiment 2

[0052] Example 2: The formula of liquid silicone rubber used as the substrate and upper packaging layer of the flexible fork finger capacitive sensor is mixed with 80wt% PDMS prepolymer and 20wt% curing agent Dow Corning 184B, and the viscosity after mixing is 1500mPa·s; used as a flexible fork The conductive rubber formula of the interdigital electrode layer of the finger capacitive sensor is 40wt% liquid silicone rubber (vinyl-terminated polydimethylsiloxane, 14Pa.s, density 1.2g / cm 3 ), 20wt% silver-plated glass fiber (silver plating amount 18wt%, aspect ratio 200μm: 8μm), 10wt% carbon fiber (aspect ratio 120μm: 8μm), 20wt% diluent (simethicone) and 10wt% synergistic Agents (1,2-propanediol) were mixed uniformly in order. Prepare according to the following steps: ①Preparation of the base layer, put the mixed liquid silicone rubber into the spray gun, spray it on the PET under the pressure of 0.6MPa to form a film, and further carry out vacuum degassing under the environment...

Embodiment 3

[0054] Embodiment 3: The formula of the liquid silicone rubber used as the substrate of the flexible finger capacitive sensor and the upper packaging layer is mixed with 87wt% PDMS prepolymer and 13wt% curing agent Dow Corning 184B, and the viscosity after mixing is 1834mPa·s; used as a flexible finger The conductive rubber formula of the interdigital electrode layer of the capacitive sensor is 50wt% liquid silicone rubber (vinyl-terminated polydimethylsiloxane, 16Pa.s, density 1.2g / cm 3), 25wt% silver-plated glass fiber (silver plating amount 18wt%, aspect ratio 200μm: 8μm), 5wt% carbon fiber (aspect ratio is 120μm: 8μm), 10wt% diluent (simethicone) 10wt% synergist (1,2-Propanediol) Mixed uniformly in order. Prepare according to the following steps: ①Preparation of the base layer, put the mixed liquid silicone rubber into the spray gun, spray it on the PET under the pressure of 0.6MPa to form a film, and further carry out vacuum degassing under the environment of -0.1MPa, Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com