High-sensitivity and high-selectivity triethylamine gas-sensitive material and preparation method thereof

A high-selectivity, gas-sensing material technology, applied in the field of high-sensitivity, high-selectivity triethylamine gas-sensing materials and its preparation, can solve the problem of shedding, difficulty in controlling particle size and load coverage, and affecting the stability of gas-sensing performance To achieve high selectivity detection, solve poor selectivity, improve sensitivity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

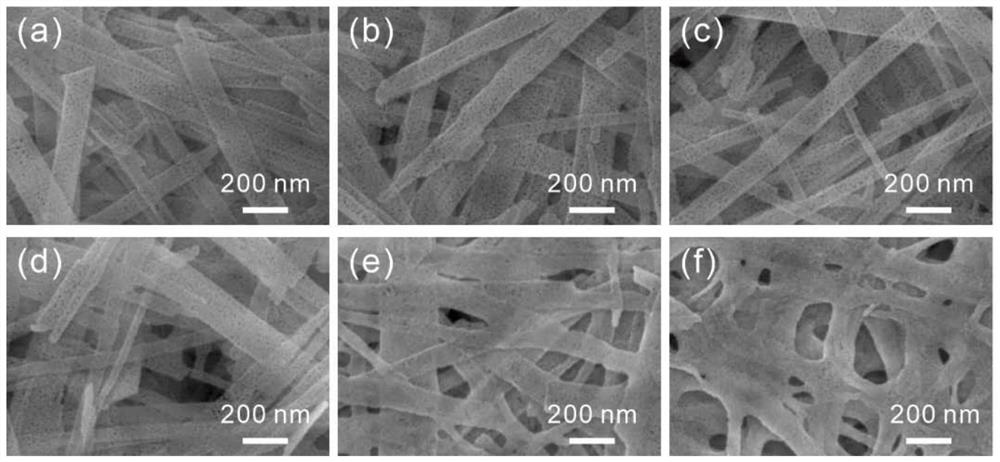

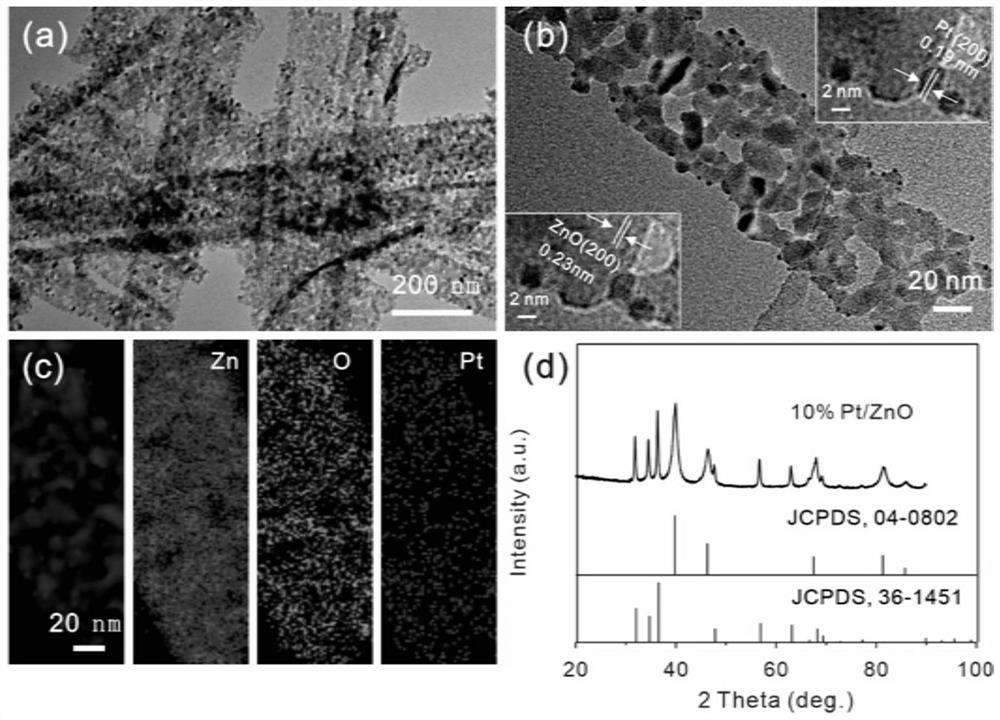

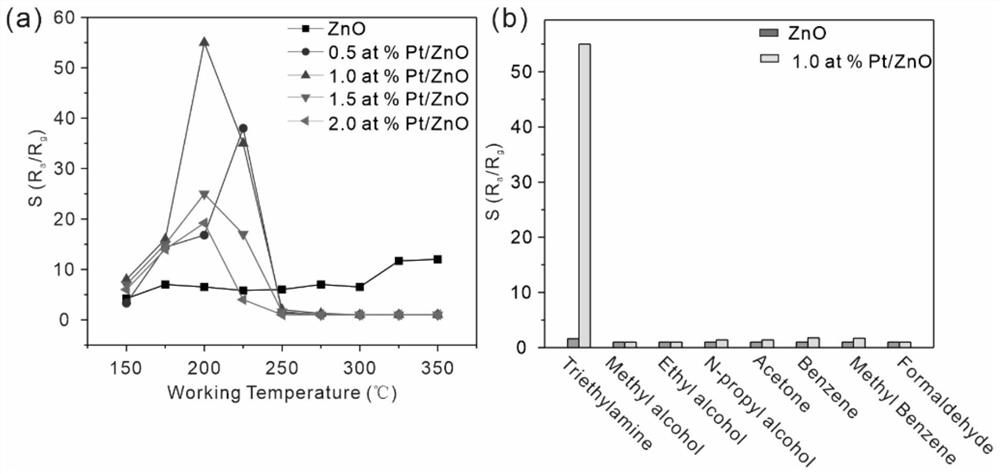

[0026] A kind of highly sensitive, highly selective triethylamine gas sensitive material, its preparation method comprises the steps:

[0027] (1) In the selenium powder solution (dissolving 0.4mmol Se powder in 20mL 80wt% hydrazine hydrate solution to obtain) that the concentration is 0.02mol / L, it is the zinc chloride aqueous solution (0.2mmol ZnCl hydrate) that concentration is 0.01mol / L 2 Dissolved in 20mL ultrapure water), stirred and mixed for 1 hour, and then hydrothermally reacted at 180°C for 12 hours. After the end, the precipitate was centrifugally washed with hydrazine hydrate 4 times to remove excess selenium powder, and then the precipitate was centrifugally washed with water until neutral. Finally, the precipitate was washed 2 times with ethanol to remove water to obtain white ZnSe 0.5N 2 h 4 Precursors of nanoribbons;

[0028] (2) 0.2mmol ZnSe·0.5N 2 h 4 The nanoribbons were dissolved in 90 mL of ethanol solution, and after stirring for 10 min, 200 μL of H ...

Embodiment 2

[0033] A kind of highly sensitive, highly selective triethylamine gas sensitive material, its preparation method comprises the steps:

[0034] (1) In the selenium powder solution (dissolving 0.4mmol Se powder in 20mL 80wt% hydrazine hydrate solution to obtain) that the concentration is 0.02mol / L, it is the zinc chloride aqueous solution (0.2mmol ZnCl hydrate) that concentration is 0.01mol / L 2 Dissolved in 20mL ultrapure water), stirred and mixed for 1 hour, and then hydrothermally reacted at 180°C for 12 hours. After the end, the precipitate was centrifugally washed with hydrazine hydrate 4 times to remove excess selenium powder, and then the precipitate was centrifugally washed with water until neutral. Finally, the precipitate was washed 2 times with ethanol to remove water to obtain white ZnSe 0.5N 2 h 4 Precursors of nanoribbons;

[0035] (2) 0.2mmol ZnSe·0.5N 2 h 4 The nanoribbons were dissolved in 90 mL of ethanol solution, and after stirring for 10 min, 100 μL of H ...

Embodiment 3

[0039] A kind of highly sensitive, highly selective triethylamine gas sensitive material, its preparation method comprises the steps:

[0040] (1) In the selenium powder solution (dissolving 0.4mmol Se powder in 20mL 80wt% hydrazine hydrate solution to obtain) that the concentration is 0.02mol / L, it is the zinc chloride aqueous solution (0.2mmol ZnCl hydrate) that concentration is 0.01mol / L 2 Dissolved in 20mL ultrapure water), stirred and mixed for 1 hour, and then hydrothermally reacted at 180°C for 12 hours. After the end, the precipitate was centrifugally washed with hydrazine hydrate 4 times to remove excess selenium powder, and then the precipitate was centrifugally washed with water until neutral. Finally, the precipitate was washed 2 times with ethanol to remove water to obtain white ZnSe 0.5N 2 h 4 Precursors of nanoribbons;

[0041] (2) 0.2mmol ZnSe·0.5N 2 h 4 The nanoribbons were dissolved in 90 mL of ethanol solution, and after stirring for 10 min, 300 μL of H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com