Method for manufacturing molybdenum-containing thin film and molybdenum-containing thin film manufactured thereby

A manufacturing method and film technology, applied in the field of molybdenum-containing films, to achieve the effect of high-end poor coverage and excellent purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

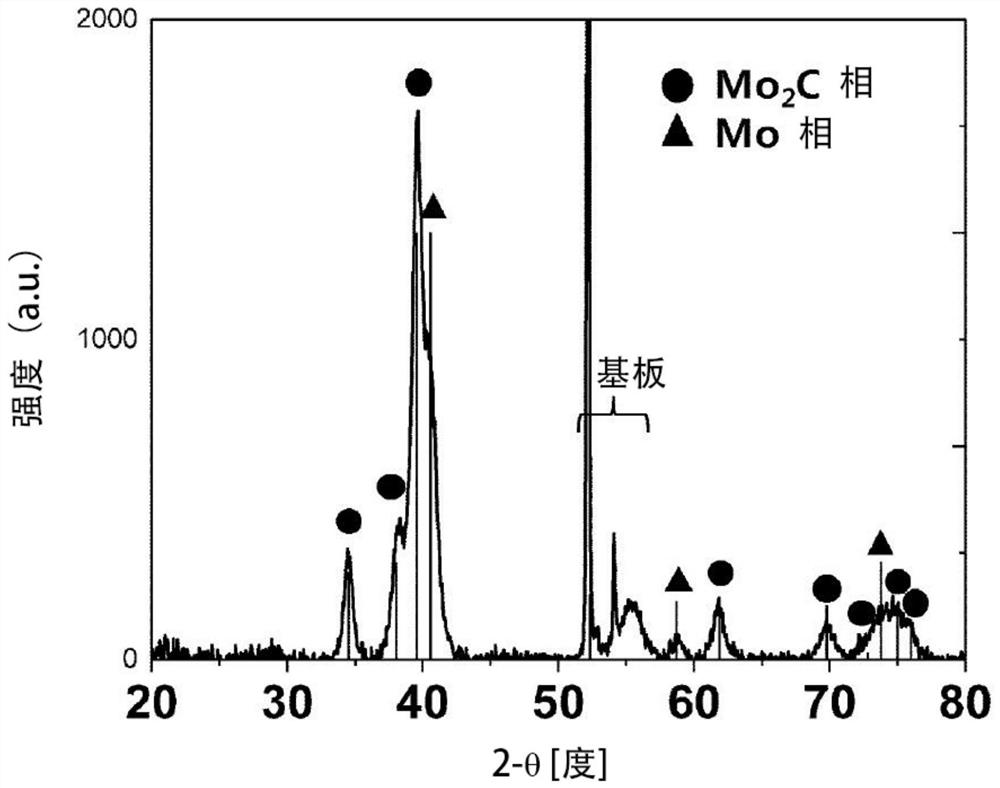

[0097] [Example 1] Manufacture of molybdenum-containing thin film

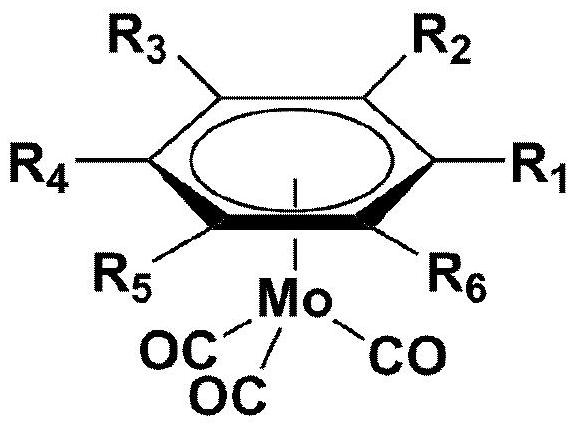

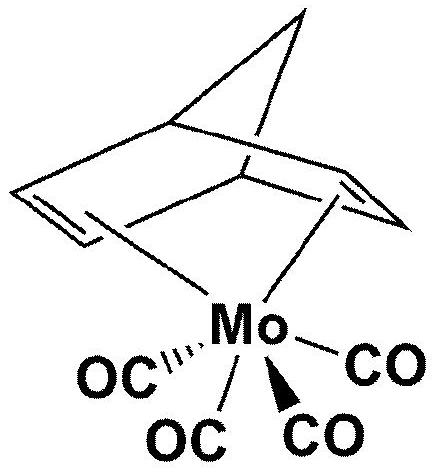

[0098] Will (Compound 1) was used as a molybdenum-containing precursor, diiodomethane (CH 2 I 2 ) is used as a reactive gas, and a molybdenum-containing thin film is formed by atomic layer deposition (Atomic layer deposition).

[0099] First, the silicon oxide film substrate was kept at 250°C, and compound 1 was filled into a stainless steel bubbling vessel and kept at 70°C. Argon gas (50 sccm) was used as a delivery gas to deliver Compound 1 vaporized in the stainless steel bubbling vessel to the silicon oxide film substrate during 1 second (0.0003 g) so that it was adsorbed on the silicon oxide film substrate. Subsequently, unreacted compound 1 was removed with argon (4000 seem) during 10 seconds. After that, diiodomethane (CH 2 I 2 ) to form molybdenum-containing films. Finally, reaction by-products and residual reaction gases were removed using argon (4000 seem) during 30 seconds. For 1 mole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com