Ganoderma lucidum Pu'er tea and processing technology

A processing technology, Pu-erh tea technology, applied in tea treatment before extraction, etc., can solve the problem of small improvement in the mixing efficiency of Ganoderma lucidum components and Pu-erh tea, and achieve the effects of improving component utilization, improving fermentation efficiency, and reducing burnt edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A Ganoderma lucidum Pu'er tea, comprising Ganoderma lucidum mixture, Pu'er tea material, and fermentation bacteria, wherein the Ganoderma lucidum mixture includes pine needle Ganoderma lucidum powder, wild thin tree Ganoderma lucidum powder, white Ganoderma powder, sessile Ganoderma lucidum powder, Phellinus Ganoderma lucidum powder, and the fermenting bacteria include The weight ratio of Corynebacterium Hercules, Ganoderma lucidum mixture, Pu'er tea material and fermentation bacteria is 0.4:1:0.02.

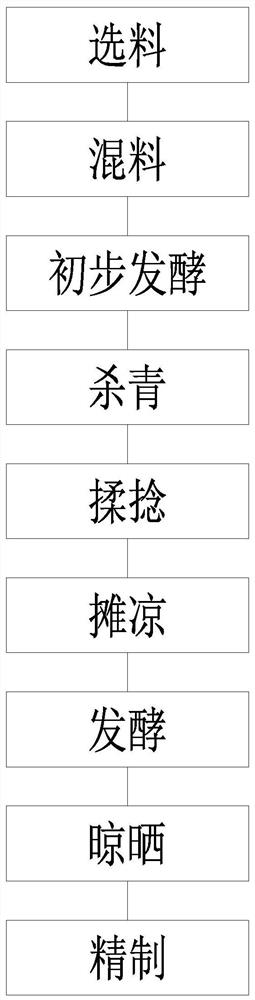

[0028] Such as figure 1 As shown, the present embodiment also discloses a processing technology of Ganoderma lucidum Pu'er tea, comprising the following steps:

[0029] Material selection: choose pine needle ganoderma powder, wild thin tree ganoderma powder, white ganoderma powder, sessile ganoderma powder, Phellinus ganoderma powder, and mix the above five ganoderma powders to make a ganoderma mixture, then mix Pu’er tea with ganoderma The mixture is mixed to obtain the ...

Embodiment 2

[0041] A Ganoderma lucidum Pu'er tea, comprising Ganoderma lucidum mixture, Pu'er tea material, and fermentation bacteria, wherein the Ganoderma lucidum mixture includes pine needle Ganoderma lucidum powder, wild thin tree Ganoderma lucidum powder, white Ganoderma powder, sessile Ganoderma lucidum powder, Phellinus Ganoderma lucidum powder, and the fermenting bacteria include The weight ratio of Corynebacterium glutamicum, Ganoderma lucidum mixture, Pu'er tea material, and fermentation bacteria is 0.2:1:0.03.

[0042] Such as figure 1 As shown, the present embodiment also discloses a processing technology of Ganoderma lucidum Pu'er tea, comprising the following steps:

[0043] Material selection: choose pine needle ganoderma powder, wild thin tree ganoderma powder, white ganoderma powder, sessile ganoderma powder, Phellinus ganoderma powder, and mix the above five ganoderma powders to make a ganoderma mixture, then mix Pu’er tea with ganoderma The mixture is mixed to obtain t...

Embodiment 3

[0055] A Ganoderma lucidum Pu'er tea, comprising Ganoderma lucidum mixture, Pu'er tea material, and fermentation bacteria, wherein the Ganoderma lucidum mixture includes pine needle Ganoderma lucidum powder, wild thin tree Ganoderma lucidum powder, white Ganoderma powder, sessile Ganoderma lucidum powder, Phellinus Ganoderma lucidum powder, and the fermenting bacteria include The weight ratio of Corynebacterium hydrocarbolyticus, Ganoderma lucidum mixture, Pu'er tea material and fermentation bacteria is 0.3:1:0.01.

[0056] Such as figure 1 As shown, the present embodiment also discloses a processing technology of Ganoderma lucidum Pu'er tea, comprising the following steps:

[0057] Material selection: choose pine needle ganoderma powder, wild thin tree ganoderma powder, white ganoderma powder, sessile ganoderma powder, Phellinus ganoderma powder, and mix the above five ganoderma powders to make a ganoderma mixture, then mix Pu’er tea with ganoderma The mixture is mixed to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com